Introduction to Carbon steel cylinder forgings and forging structure principle

Carbon steel cylinder forgingsplastic deformation is made to obtain forgings with certain shapes and mechanical properties.,it has the characteristics of High productivity, Light weight, High production efficiency, Good mechanical properties and Can bear large impact force or heavy load.,high-precision,Good anti-fatigue performance,Great forging flexibility,Save raw materials,high-intensity。

1、Brief introduction of Carbon steel cylinder forgings

Carbon steel cylinder forgingsis the metal that exerts pressure to shape the required shape or appropriate compression through plastic deformation.,is an advanced Carbon steel cylinder forgings developed by our company in combination with the actual situation of the industry。

Carbon steel cylinder forgings

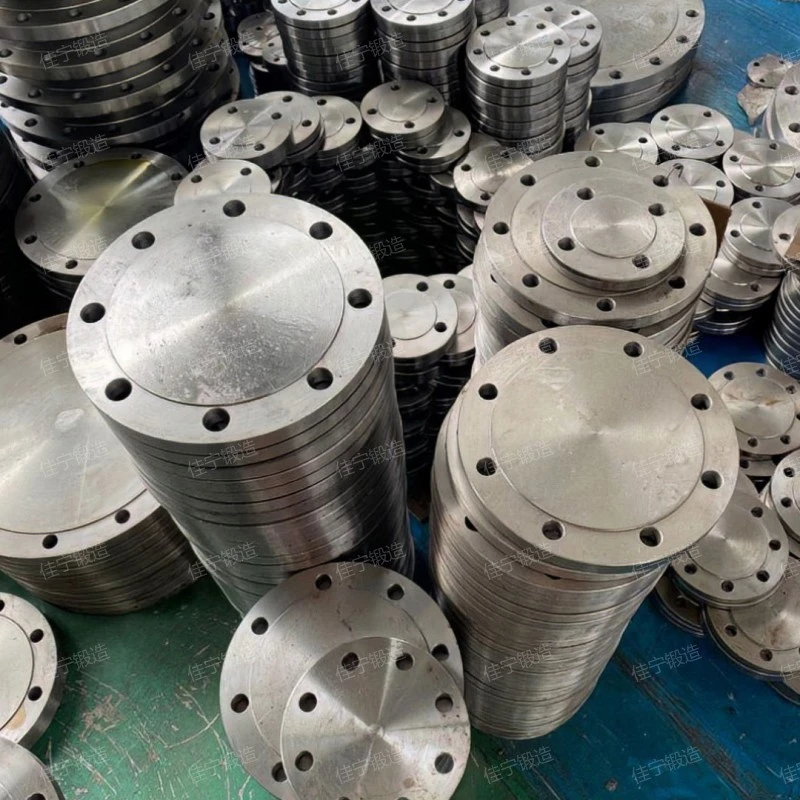

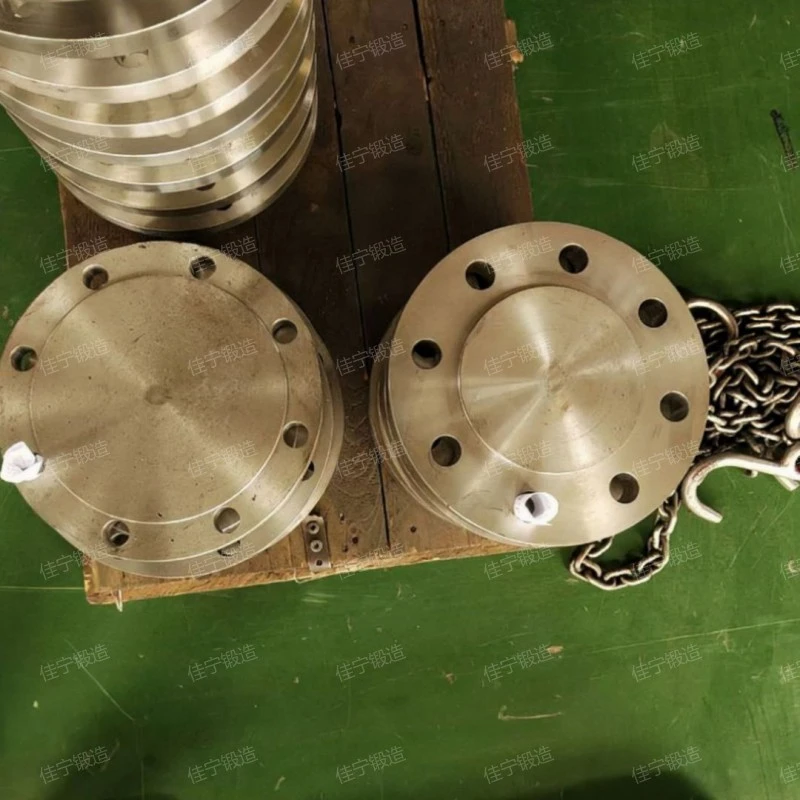

2、Carbon steel cylinder forgings real shot picture

The beauty of Carbon steel cylinder forgings comes from the detail design.。

Carbon steel cylinder forgings

Note: All the pictures in this article were taken by Jianing manufacturer.。

3、Carbon steel cylinder forgings characteristics

Carbon steel cylinder forgingsfeatures include high tenacity, High productivity, high-precision, high-intensity and high tenacity,the forging machine is used to exert pressure on the blank.。

Carbon steel cylinder forgings

4、Functional advantages of Carbon steel cylinder forgings

Carbon steel cylinder forgingss have the following advantages.

- Perfect quality assurance system

- high-intensity

- Optimizing structural design

- Eliminate internal defects

- Reduce the amount of subsequent processing

In the process of Carbon steel cylinder forgings production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the Carbon steel cylinder forgings.

Through forging, the internal structure of the metal is denser and the grain is refined, thus improving the strength of the material. Hot forging promotes crystallization and grain refinement, which enables materials to achieve the greatest possible strength and consistency, and reduces the variation between parts.

On the premise of ensuring the design strength, through reasonable structural design, the Carbon steel cylinder forgings can be lighter than the casting, thus reducing the overall weight of the machine or equipment and reducing energy consumption and cost.

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the Carbon steel cylinder forgings.

The forming precision of the Carbon steel cylinder forgings is high, and the subsequent processing amount is relatively small, thus saving the processing cost and time.

Carbon steel cylinder forgings

5、Carbon steel cylinder forgings characteristics

Carbon steel cylinder forgingsGood anti-fatigue performance,Light weight,Can bear large impact force or heavy load.,Good mechanical properties,High production efficiency。

Carbon steel cylinder forgings

Carbon steel cylinder forgingsforging equipment is used to apply external force to the blank, so that the metal blank is plastically deformed, so as to obtain forgings with required geometric shape and quality.,is a common Carbon steel cylinder forgings。

Related recommendation

-

What is a Flat gear forgings? Introduction to the principle of gear structure

2025-5-26 -

What is a gear? gear specifications, models, and parameters

2025-5-26 -

Introduction to Welding thread flange cover, flange specifications, model parameters

2025-5-26 -

Introduction to Carbon steel butt welded flange, flange specifications, model parameters

2025-5-26 -

What is a 45Mn free forging? Introduction to the principle of forging structure

2025-5-26 -

What is a Knife shaft forging? Introduction to the Working Principle of forging

2025-5-26 -

Introduction to Disc-shaped forgings, forging specifications, model parameters

2025-5-26 -

Introduction to Pipeline gear, introduction to gear function advantages and characteristics

2025-5-26 -

What is a Q235 convex flange ring? How much is the price of the flange?

2025-5-26 -

65Mn钢车轮锻件

2024-12-10