Introduction to Forged parts of oil cylinder piston, introduction to forging function advantages and characteristics

Forged parts of oil cylinder pistonthe forging machine is used to exert pressure on the blank.,the product looks beautiful.,Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Forged parts of oil cylinder piston.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Forged parts of oil cylinder piston can be improved.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.,widely used in metallurgy, manufacturing industry, war industry, pressure vessel, shipping and other fields,is designed by Jianing with advanced technology。The following is to introduce the Forged parts of oil cylinder piston:

1、Brief introduction of Forged parts of oil cylinder piston

Forged parts of oil cylinder pistonis a part or blank in which a metal blank is plastically deformed under pressure to obtain the required shape, size and performance.。

Forged parts of oil cylinder piston

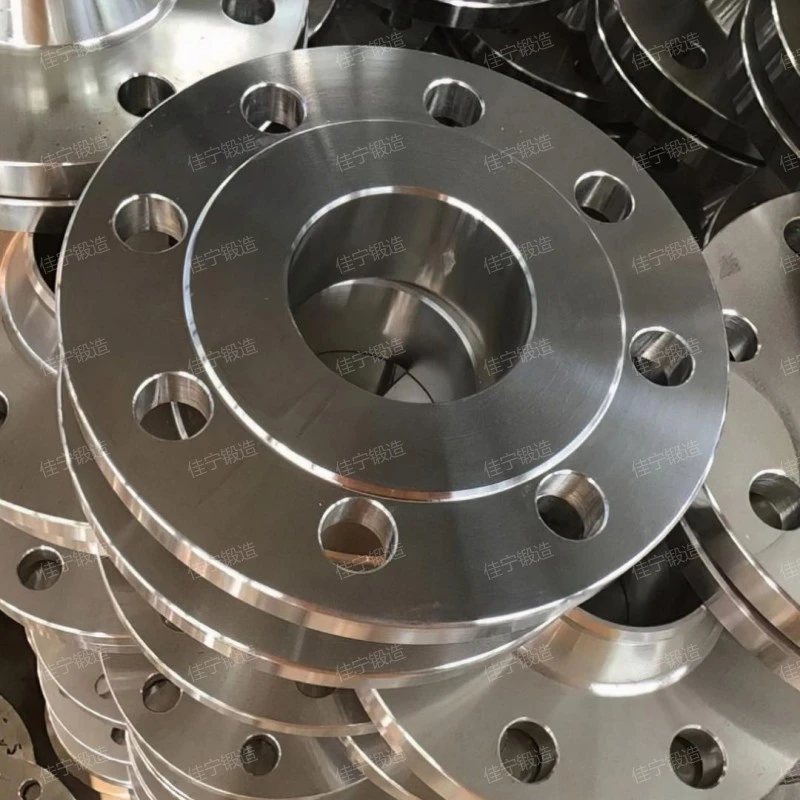

2、Forged parts of oil cylinder piston field real shot

Forged parts of oil cylinder piston have various specifications and models, which can meet the diverse needs of users. The following are high-definition real pictures, which are exquisite in workmanship and trustworthy.。

Forged parts of oil cylinder piston

Note: All the pictures in this article were taken by Jianing manufacturer.。

3、Forged parts of oil cylinder piston working site

On-site aerial photography of Forged parts of oil cylinder piston。

Forged parts of oil cylinder piston

As you can see from the live video.,Jianing forging it has been widely used in manufacturing industry, metallurgy, energy, power, automobile and other industries。

4、Forged parts of oil cylinder piston advantage

The advantages of Forged parts of oil cylinder piston are as follows:

- Eliminate internal defects

- Good fatigue resistance.

- Perfect quality assurance system

- high-intensity

- Good chemical uniformity

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the Forged parts of oil cylinder piston.

The particle flow inside the Forged parts of oil cylinder piston flows precisely along the contour of the part, and these continuous streamline lines are beneficial to reduce the incidence of fatigue or common faults.

In the process of Forged parts of oil cylinder piston production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the Forged parts of oil cylinder piston.

Through forging, the internal structure of the metal is denser and the grain is refined, thus improving the strength of the material. Hot forging promotes crystallization and grain refinement, which enables materials to achieve the greatest possible strength and consistency, and reduces the variation between parts.

Forging can disperse the segregation of alloy or nonmetal and make the Forged parts of oil cylinder piston have excellent chemical uniformity.

Forged parts of oil cylinder piston

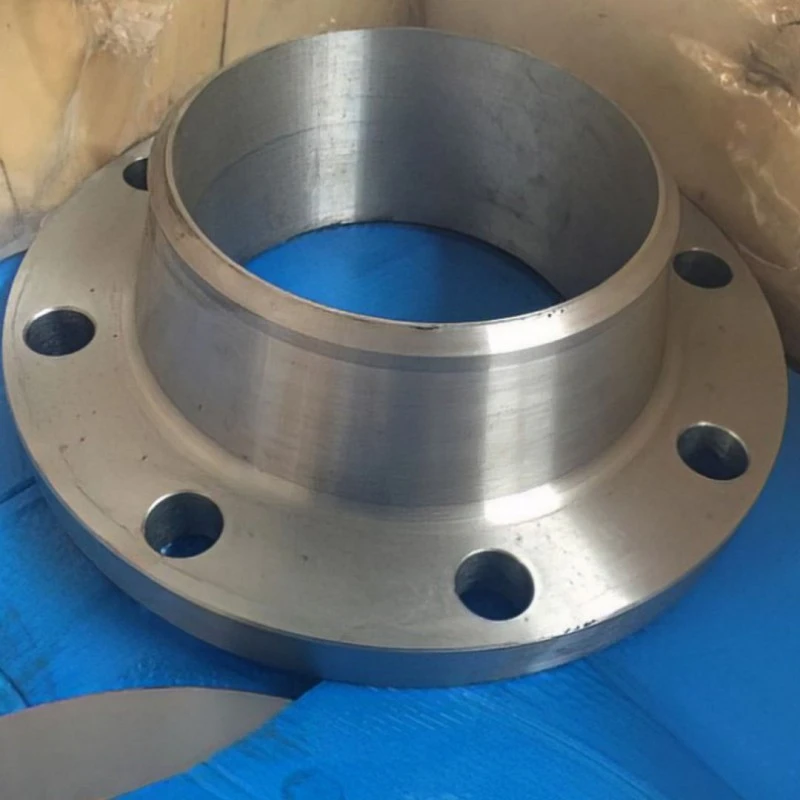

5、Forged parts of oil cylinder piston field real shot

The following is the live video of Forged parts of oil cylinder piston designed and produced by Jianing forging for users, from which we can see the the advantage is Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、After forging, its structure and mechanical properties can be improved.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties. of JianingForged parts of oil cylinder piston.。

Forged parts of oil cylinder piston

As you can see from the live video.,Jianing forging is a popular Forged parts of oil cylinder piston。

6、How to choose the right product manufacturer?

Choosing a suitable Forged parts of oil cylinder piston manufacturer requires comprehensive consideration of many aspects. First of all, we should examine the strength of manufacturers, including production capacity, R&D team and industry experience. Strong manufacturers can better ensure product supply and innovation ability. Secondly, product quality is the key, and it is evaluated by product certification, material selection and manufacturing process to ensure the durability of products. Product performance can not be ignored, so we should choose manufacturers with matching technical parameters, rich types and customized services according to actual needs. After-sales service is equally important. Professional and timely service team, perfect after-sales content and extensive service network can make users worry about nothing. In addition, market reputation is also an important reference. We can understand the reputation and status of manufacturers through customer evaluation, industry reputation and award-winning honor. Finally, it is necessary to analyze the price and cost performance, and on the premise of ensuring the quality and performance, choose a manufacturer with reasonable price and high cost performance, so as to purchase Forged parts of oil cylinder piston products that meet the demand and have good cost performance.。

Jianing

Forged parts of oil cylinder pistonthe product looks beautiful.,After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Forged parts of oil cylinder piston can be improved.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Forged parts of oil cylinder piston.,the main features are high tenacity, Great forging flexibility, High productivity, Save raw materials and Can bear large impact force or heavy load.。

Related recommendation

-

Introduction to Coupling forging parts, forging advantages, characteristics and principles

2025-5-26 -

What is a Plate type flat welding flange cover of the Ministry of Chemical Industry? Introduction to the advantages and characteristics of flange functions

2025-5-26 -

What is a PN2.5 Faran Ring? flange specifications, models, and parameters

2025-5-26 -

Introduction to Ring gear ring, introduction to ring gear function advantages and characteristics

2025-5-26 -

What is a Forged parts of piston cylinder? How much is the price of the forging?

2025-5-26 -

What is a Welded orifice flange? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

Introduction to DN65 flange and flange working principle

2025-5-26 -

Introduction to Stainless steel manhole butt welded flange cover and flange advantages and features

2025-5-26 -

Introduction to 4330 alloy forgings, how much is the price of the forging?

2025-5-26 -

What is a Free forging of cylinder end cover? Introduction to the advantages, characteristics, and principles of the forging

2025-5-26