What is a Cylinder back cover forging? forging specifications, models, and parameters

Cylinder back cover forgingis the metal that exerts pressure to shape the required shape or appropriate compression through plastic deformation.,the product looks beautiful.。The following is to introduce the Cylinder back cover forging:

1、Brief introduction of Cylinder back cover forging

Cylinder back cover forgingrefers to the workpiece or blank obtained by forging metal blank. In the process of forging, the metal blank is plastically deformed under the pressure of forging hammer, press and other equipment, and then its shape, size and organizational structure are changed to meet specific use requirements.,was developed and designed by Jianing。

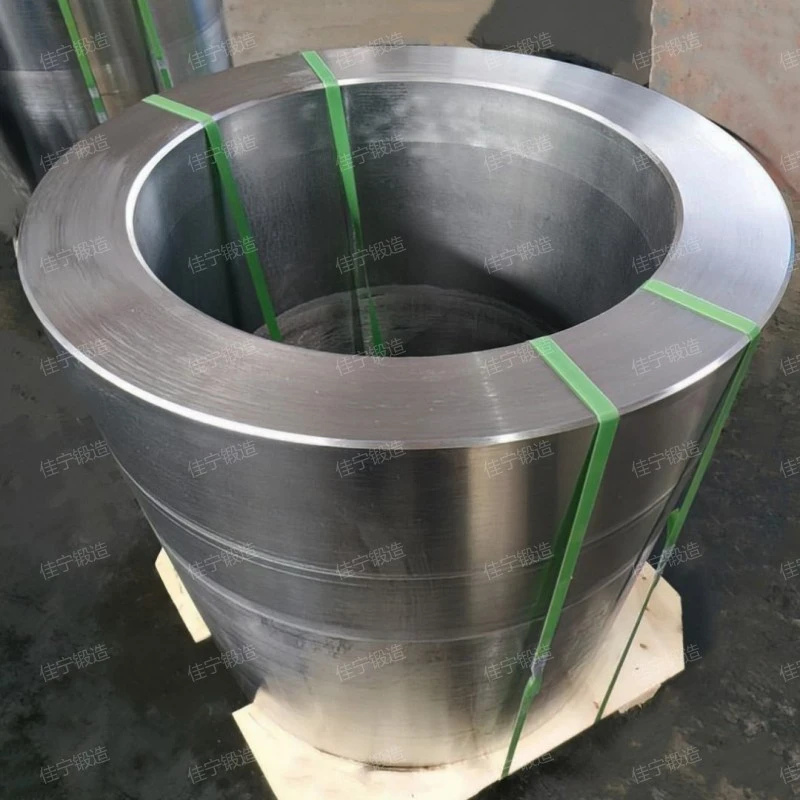

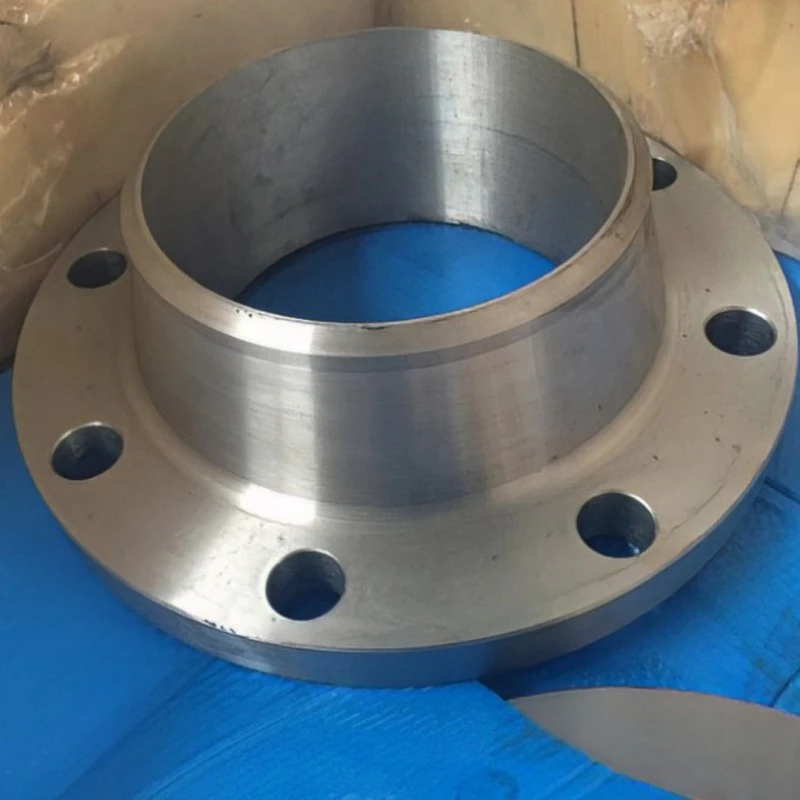

Cylinder back cover forging

2、Cylinder back cover forging performance advantage

Cylinder back cover forgings have the following advantages.

- High dimensional accuracy

- Optimizing structural design

- Perfect quality assurance system

- Good chemical uniformity

- Eliminate internal defects

In the forging process of Cylinder back cover forging, high dimensional accuracy and shape accuracy can be obtained through the precise forming of dies.

On the premise of ensuring the design strength, through reasonable structural design, the Cylinder back cover forging can be lighter than the casting, thus reducing the overall weight of the machine or equipment and reducing energy consumption and cost.

In the process of Cylinder back cover forging production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the Cylinder back cover forging.

Forging can disperse the segregation of alloy or nonmetal and make the Cylinder back cover forging have excellent chemical uniformity.

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the Cylinder back cover forging.

Cylinder back cover forging

3、Cylinder back cover forging video detail

Jianing provides customers with on-site high-definition video, fully demonstrates the advantages of on-site productt operation, and helps customers to deeply understand the Cylinder back cover forging production process and production site, and gain favorable comments and recognition from customers.。

Cylinder back cover forging

As you can see from the live video.,Shanxi jianing forging co., ltd is a workpiece or blank obtained by forging and deforming a metal blank.。

4、Cylinder back cover forging field real shot

Cylinder back cover forging styles and designs are diverse, specifications and models can be customized according to customer needs, providing high-definition pictures for new and old customers' reference.。

Cylinder back cover forging

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

5、Cylinder back cover forging characteristics

Cylinder back cover forgingfeatures include Good mechanical properties, Good mechanical properties, Good anti-fatigue performance, High production efficiency and high-intensity,is a Cylinder back cover forging newly developed by Jianing forging。

Cylinder back cover forging

6、Jianing's strength

The company has many years of Cylinder back cover forging manufacturing experience, large scale and strong strength.。

Jianing forging

Cylinder back cover forgingit has the characteristics of Light weight, Save raw materials, Great forging flexibility, high tenacity and high-precision,is a kind of high quality and low price Cylinder back cover forging,it is widely used in pressure vessel, manufacturing industry, shipping, metallurgy and construction machinery。

Related recommendation

-

回转支承环锻件

2024-12-10 -

What is a Q345e flat welding flange plate? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

Introduction to Welding special-shaped flange, introduction to flange function advantages and characteristics

2025-5-26 -

What is a 201 stainless steel flat welding flange plate? Introduction to the advantages and characteristics of the flange

2025-5-26 -

What is a Q275D Carbon Steel Forging Parts? Introduction to the principle of forging structure

2025-5-26 -

What is a American standard forged parts? Introduction to the advantages, characteristics, and principles of the forging

2025-5-26 -

What is a Welding irregular flange ring? Introduction to the principle of flange structure

2025-5-26 -

What is a Variable diameter convex surface flat welding flange cover? flange specifications, models, and parameters

2025-5-26 -

Introduction to Suspension rod forging parts, introduction to forging advantages and characteristics

2025-5-26 -

Introduction to Convex flat welded steel flange ring, flange advantages, characteristics and principles

2025-5-26