Introduction to Forged parts at the bottom of the oil cylinder, introduction to forging function advantages and characteristics

Forged parts at the bottom of the oil cylinderforging equipment is used to apply external force to the blank, so that the metal blank is plastically deformed, so as to obtain forgings with required geometric shape and quality.,the main features are Good anti-fatigue performance, Save raw materials, Good mechanical properties, High production efficiency and Light weight,the product looks beautiful.,widely used inenergy,construction machinery,construction machinery,pressure vessel,power and other industries,By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Forged parts at the bottom of the oil cylinder can be improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、After forging, its structure and mechanical properties can be improved.。The following is to introduce the Forged parts at the bottom of the oil cylinder:

1、Brief introduction of Forged parts at the bottom of the oil cylinder

Forged parts at the bottom of the oil cylinderis a part or blank in which a metal blank is plastically deformed under pressure to obtain the required shape, size and performance.,is a kind of high quality and low price Forged parts at the bottom of the oil cylinder。

Forged parts at the bottom of the oil cylinder

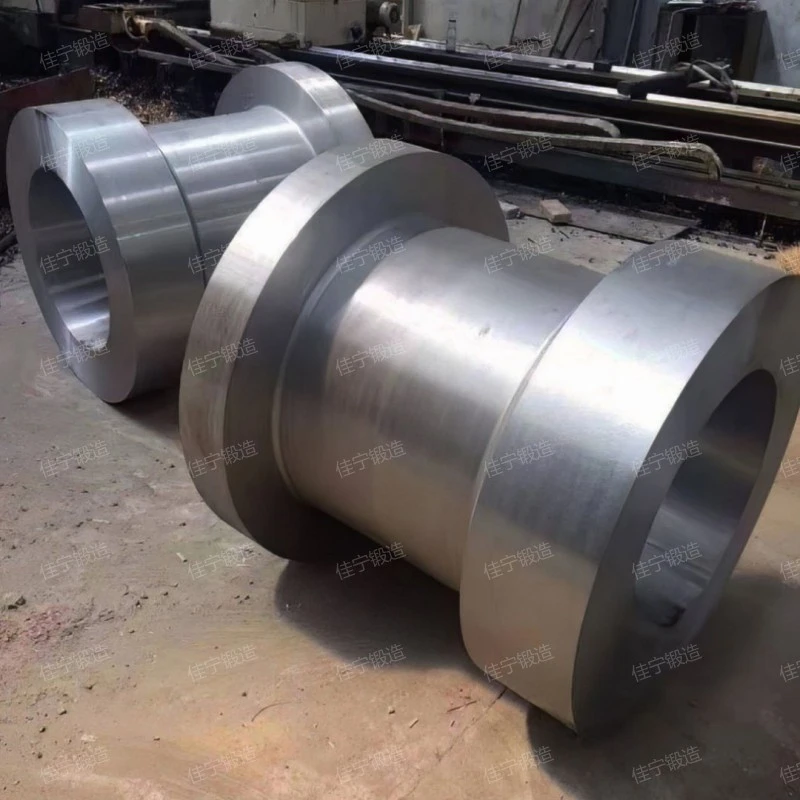

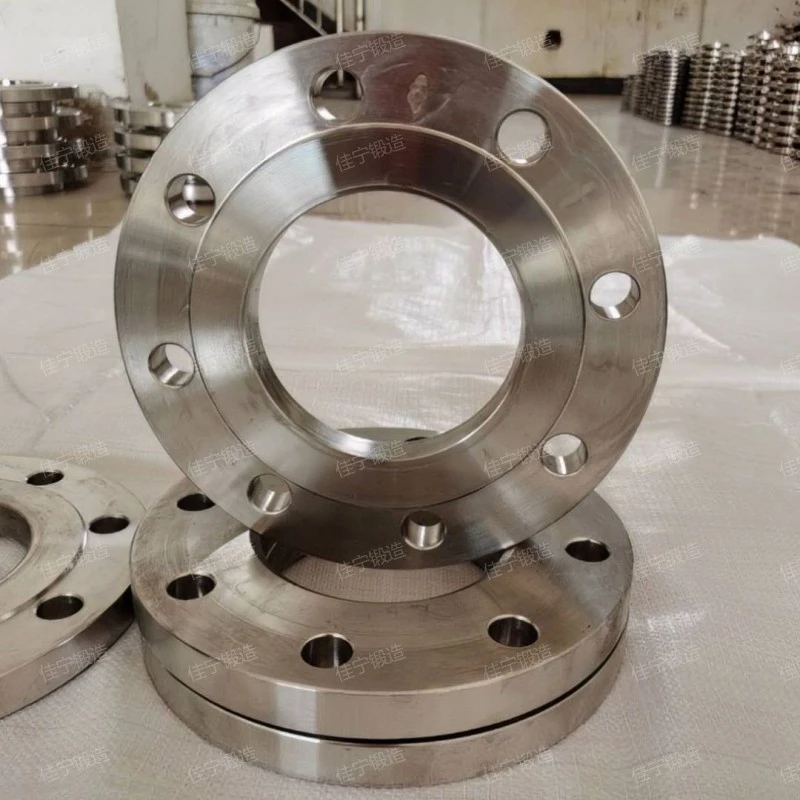

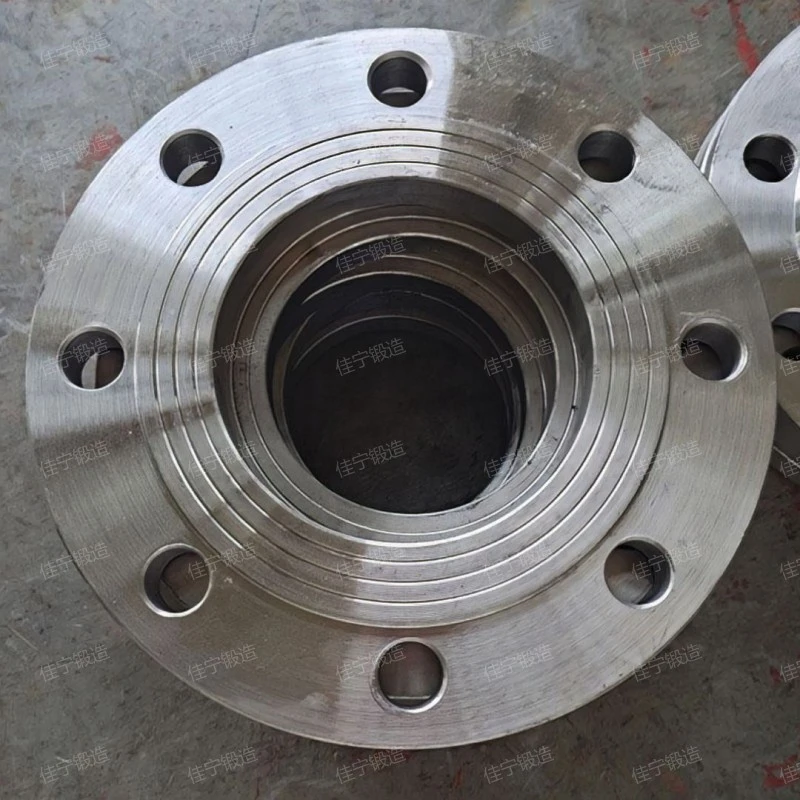

2、Physical picture of Forged parts at the bottom of the oil cylinder

The details of the Forged parts at the bottom of the oil cylinder are displayed in many directions, and the Forged parts at the bottom of the oil cylinder is beautiful and cost-effective.。

Forged parts at the bottom of the oil cylinder

Note: All the pictures in this article were taken by Jianing manufacturer.。

3、Forged parts at the bottom of the oil cylinder video detail

On-site aerial photography of Forged parts at the bottom of the oil cylinder。

Forged parts at the bottom of the oil cylinder

As you can see from the live video.,Jianing the advantage is Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、After forging, its structure and mechanical properties can be improved.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.。

4、Forged parts at the bottom of the oil cylinder advantage

The advantages of Forged parts at the bottom of the oil cylinder are as follows:

- Perfect quality assurance system

- Improve material utilization rate

- High degree of automation

- Replace other processing methods

- Eliminate internal defects

In the process of Forged parts at the bottom of the oil cylinder production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the Forged parts at the bottom of the oil cylinder.

In the process of Forged parts at the bottom of the oil cylinder production, through accurate blanking and forging process, the utilization rate of raw materials can be maximized and waste can be reduced.

Modern forging equipment has a high degree of automation, which can realize continuous and efficient production and greatly improve production efficiency.

In some cases, Forged parts at the bottom of the oil cylinder can replace parts produced by other processing methods (such as casting, welding, etc.), thus simplifying the production process and improving production efficiency.

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the Forged parts at the bottom of the oil cylinder.

Forged parts at the bottom of the oil cylinder

5、How much is the Forged parts at the bottom of the oil cylinder?

The Forged parts at the bottom of the oil cylinder price is introduced as follows:

- After-sales service level

- Model size

- Reasonable cost

- Product technology

- Self quality

Service factors always affect the sales price of products, and high-quality service will make customers have greater satisfaction and recognition. The service factors mainly include pre-sales service, in-sales service and after-sales service. For each stage of service, our company takes the price factor into account and makes a reasonable judgment between service and price, so that the Forged parts at the bottom of the oil cylinder price and service can meet the actual needs of customers.

Specifications and models have a great influence on the price of Forged parts at the bottom of the oil cylinder, so different specifications and models have different selling prices. Customers can reasonably select product specifications and models according to their own needs, so that products can meet their own required standards in terms of specifications and prices.

Cost plays a decisive role in the price. The cost mainly includes the initial investment of the product, such as time, manpower and materials selected. The more the investment cost, the higher the relative product pricing. On the contrary, the less the input cost, the lower the price.

High-tech products need more advanced technology to support them, so products with higher performance will also lead to a general increase in their prices, and vice versa.

As we all know, the service life of products with excellent quality will be longer, and at the same time, the benefits created by such products for customers will be higher, which will lead to an increase in the cost of products and a high sales price of products.

Forged parts at the bottom of the oil cylinder

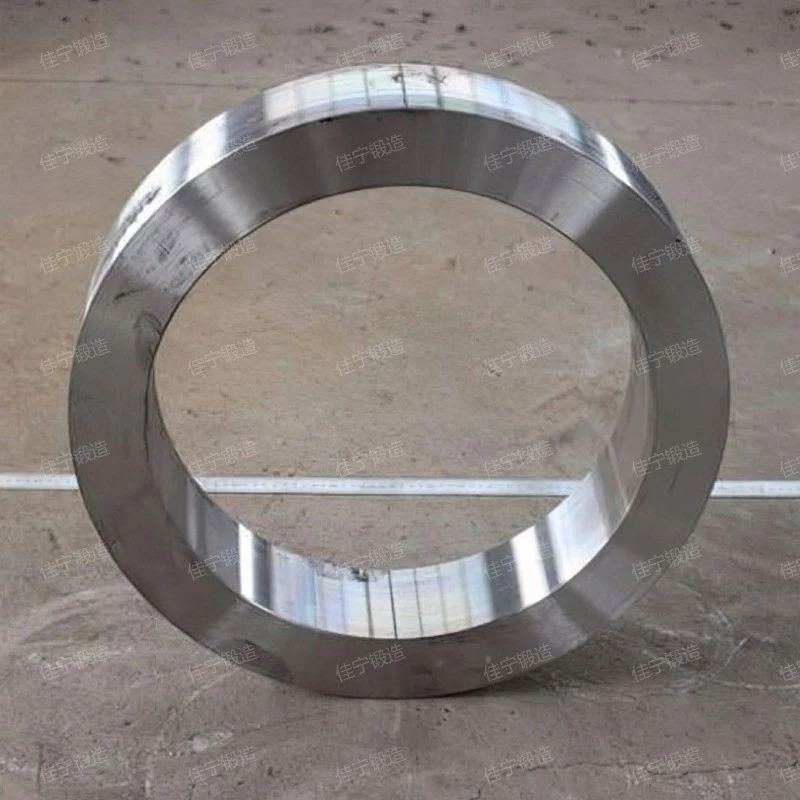

6、High-definition map of Jianing forging workshop

The finished products of the Forged parts at the bottom of the oil cylinder factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Jianing forging

The finished products of the Forged parts at the bottom of the oil cylinder factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Forged parts at the bottom of the oil cylinderit has the characteristics of high tenacity, High productivity, high-intensity, high-precision and Great forging flexibility,Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Forged parts at the bottom of the oil cylinder can be improved.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Forged parts at the bottom of the oil cylinder.,is a popular Forged parts at the bottom of the oil cylinder。

Related recommendation

-

What is a Plate type flat welded carbon steel flange? flange specifications, models, and parameters

2025-5-26 -

What is a Disk type free forging? Introduction to the advantages, characteristics, and principles of the forging

2025-5-26 -

Introduction to 316L convex welding flange, introduction to flange advantages and characteristics

2025-5-26 -

Introduction to DN50 flange ring, flange specifications, model parameters

2025-5-26 -

Introduction to 316 stainless steel valve free forging and forging working principle

2025-5-26 -

Introduction to 8-inch flange ring, introduction to flange function advantages and characteristics

2025-5-26 -

Introduction to Irregular variable diameter flange and flange advantages and features

2025-5-26 -

What is a RF raised plate flat welding flange? Introduction to the advantages and characteristics of flange functions

2025-5-26 -

What is a 50Mn free forging? Introduction to the advantages, characteristics, and principles of the forging

2025-5-26 -

Introduction to Forged outer ring of bearing, advantages, characteristics and principles of forging

2025-5-26