Introduction to Round sleeve forging parts, how much is the price of the forging?

Round sleeve forging partsplastic deformation is made to obtain forgings with certain shapes and mechanical properties.,the product looks beautiful.,it is an ideal choice for customers to buy Round sleeve forging parts。The following is to introduce the Round sleeve forging parts:

1、Brief introduction of Round sleeve forging parts

Round sleeve forging partsthe forging machine is used to exert pressure on the blank.。

Round sleeve forging parts

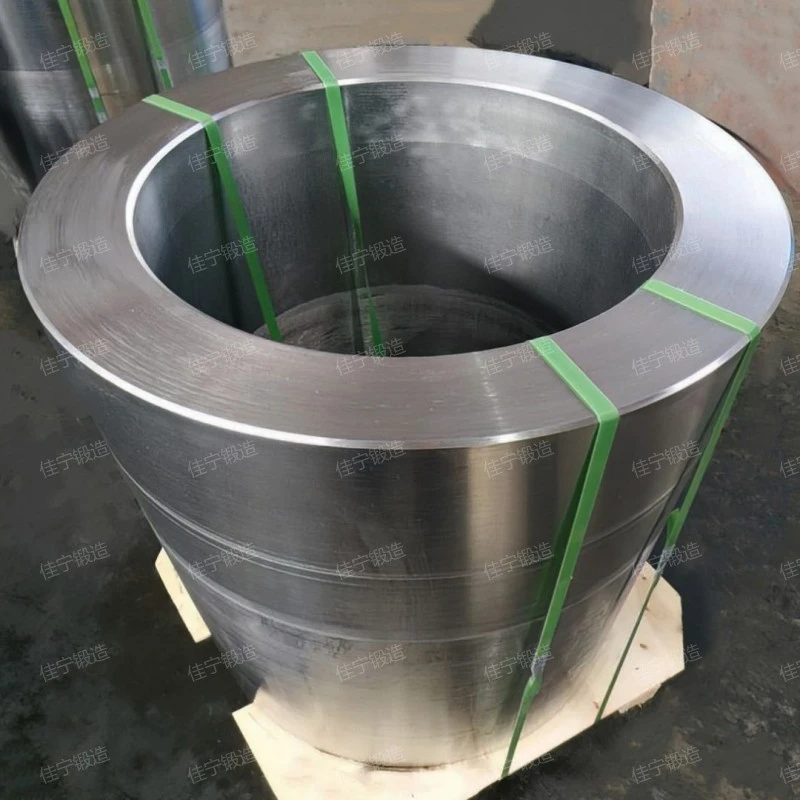

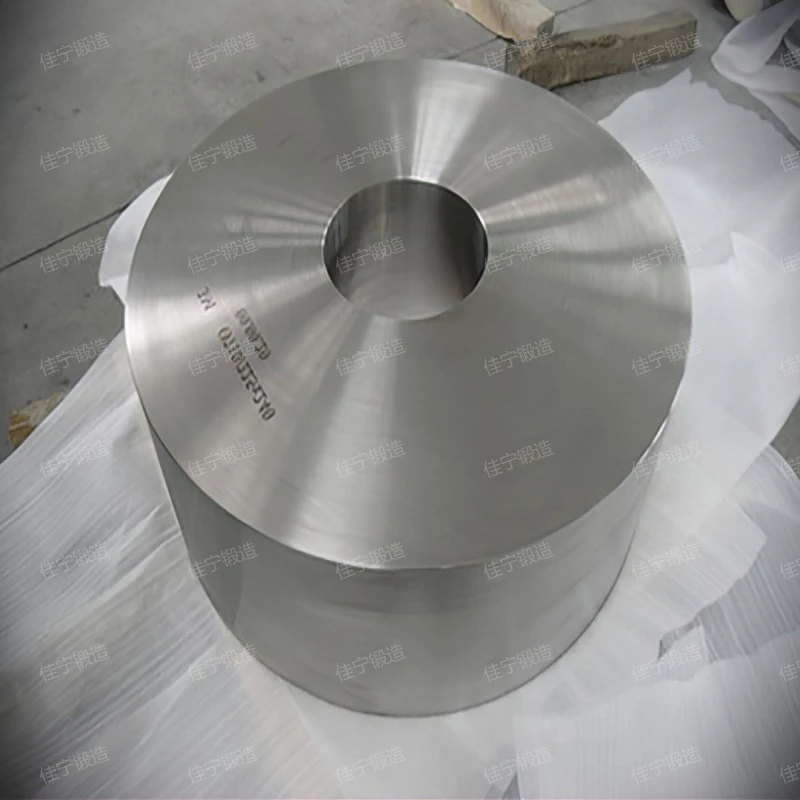

2、Round sleeve forging parts display

The omni-directional high-definition real shot of the Round sleeve forging parts is shown as follows to meet the purchase needs of our customers.。

Round sleeve forging parts

Note: All the pictures in this article were taken by Jianing manufacturer.。

3、Round sleeve forging parts advantage

The advantages of Round sleeve forging parts are as follows:

- Meet the requirements of complex working conditions

- High dimensional accuracy

- Reduce the amount of subsequent processing

- Replace other processing methods

- Optimizing structural design

The Round sleeve forging parts has excellent mechanical properties and structural integrity, which can meet the use requirements under complex working conditions and ensure the long-term stable operation of the equipment.

In the forging process of Round sleeve forging parts, high dimensional accuracy and shape accuracy can be obtained through the precise forming of dies.

The forming precision of the Round sleeve forging parts is high, and the subsequent processing amount is relatively small, thus saving the processing cost and time.

In some cases, Round sleeve forging parts can replace parts produced by other processing methods (such as casting, welding, etc.), thus simplifying the production process and improving production efficiency.

On the premise of ensuring the design strength, through reasonable structural design, the Round sleeve forging parts can be lighter than the casting, thus reducing the overall weight of the machine or equipment and reducing energy consumption and cost.

Round sleeve forging parts

4、Functional advantages of Round sleeve forging parts

Round sleeve forging partss have the following advantages.

- Good chemical uniformity

- Eliminate internal defects

- high-intensity

- High dimensional accuracy

- High degree of automation

Forging can disperse the segregation of alloy or nonmetal and make the Round sleeve forging parts have excellent chemical uniformity.

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the Round sleeve forging parts.

Through forging, the internal structure of the metal is denser and the grain is refined, thus improving the strength of the material. Hot forging promotes crystallization and grain refinement, which enables materials to achieve the greatest possible strength and consistency, and reduces the variation between parts.

In the forging process of Round sleeve forging parts, high dimensional accuracy and shape accuracy can be obtained through the precise forming of dies.

Modern forging equipment has a high degree of automation, which can realize continuous and efficient production and greatly improve production efficiency.

Round sleeve forging parts

5、Round sleeve forging parts quotation

The Round sleeve forging parts price is introduced as follows:

- product function

- Low cost of raw materials

- region

- Manufacturer's sales model

- quality

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

When the Round sleeve forging parts is produced, the materials selected by different manufacturers will be different. Some manufacturers use high-quality materials, and the price will be relatively high, while some manufacturers use ordinary materials, and the price will be lower.

Geographical location also has a certain influence on the formulation of price, because there is a close relationship between geographical location and transportation cost. Generally, the price of places with superior geographical location will be more fair, which is lower than that of those remote cities. Jianing forging address:Shanxi, where the traffic is very developed and convenient, provides a series of conveniences for the distribution of products to a great extent.

Jianing forging has long used the sales method of small profits but quick turnover to sell products, and the product price, market price and ex-factory price are the same. The purpose of this is to improve the sales volume of products and the visibility of enterprises.

Generally speaking, the higher the product quality, the higher the Round sleeve forging parts price. A reasonable balance is made between quality and price, so that the comprehensive quality of the product can meet the customer's use standards and meet the basic needs of customers in terms of price.

Round sleeve forging parts

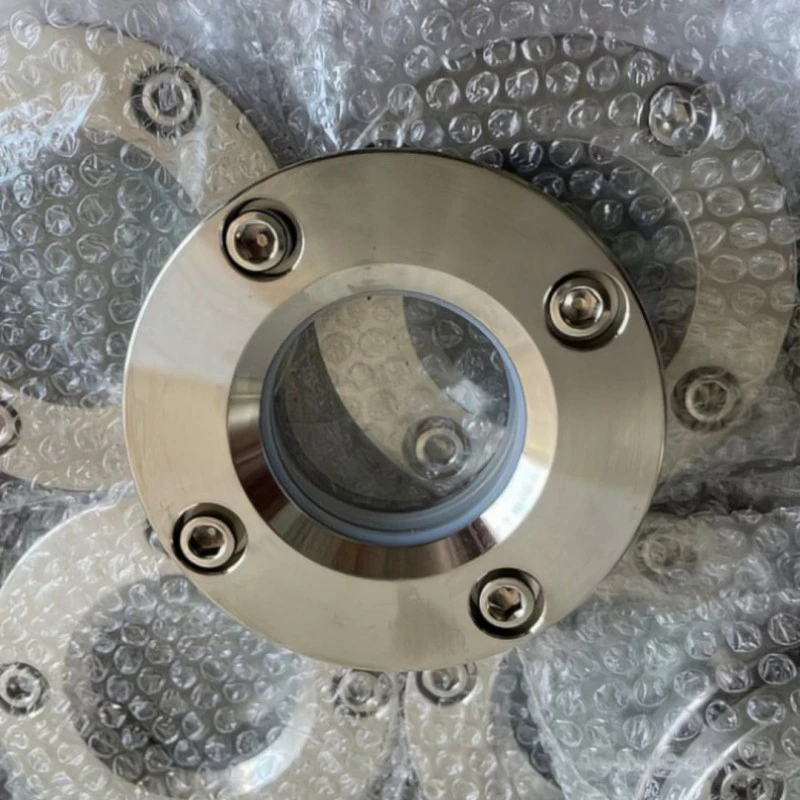

6、Jianing forging workshop real shot

The finished products of the Round sleeve forging parts factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Jianing

The finished products of the Round sleeve forging parts factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Round sleeve forging partsAfter forging, its structure and mechanical properties can be improved.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.,High productivity,high-intensity,Can bear large impact force or heavy load.,Can bear large impact force or heavy load.,Light weight,refers to the workpiece or blank obtained by forging metal blank.。

Related recommendation

-

Introduction to Clamp on flat welding flange and flange working principle

2025-5-26 -

Introduction to Secondary pressure vessel forgings, introduction to forging function advantages and characteristics

2025-5-26 -

Introduction to Free forging of pressure steel, advantages, characteristics and principles of forging

2025-5-26 -

Introduction to Convex steel butt welded flange ring, flange specifications, model parameters

2025-5-26 -

What is a 310s flat welding flange cover? flange specifications, models, and parameters

2025-5-26 -

9Cr2Mo轧辊毛坯锻件

2024-12-10 -

Introduction to Rolling ring free forging, introduction to forging function advantages and characteristics

2025-5-26 -

Introduction to Pressure bearing gear forgings and gear structure principle

2025-5-26 -

Introduction to First level pressure vessel forgings and forging advantages and features

2025-5-26 -

What is a Q275C carbon steel forged parts? forging specifications, models, and parameters

2025-5-26