Introduction to First level pressure vessel forgings and forging advantages and features

First level pressure vessel forgingsrefers to the workpiece or blank obtained by forging metal blank.。The following is to introduce the First level pressure vessel forgings:

1、Brief introduction of First level pressure vessel forgings

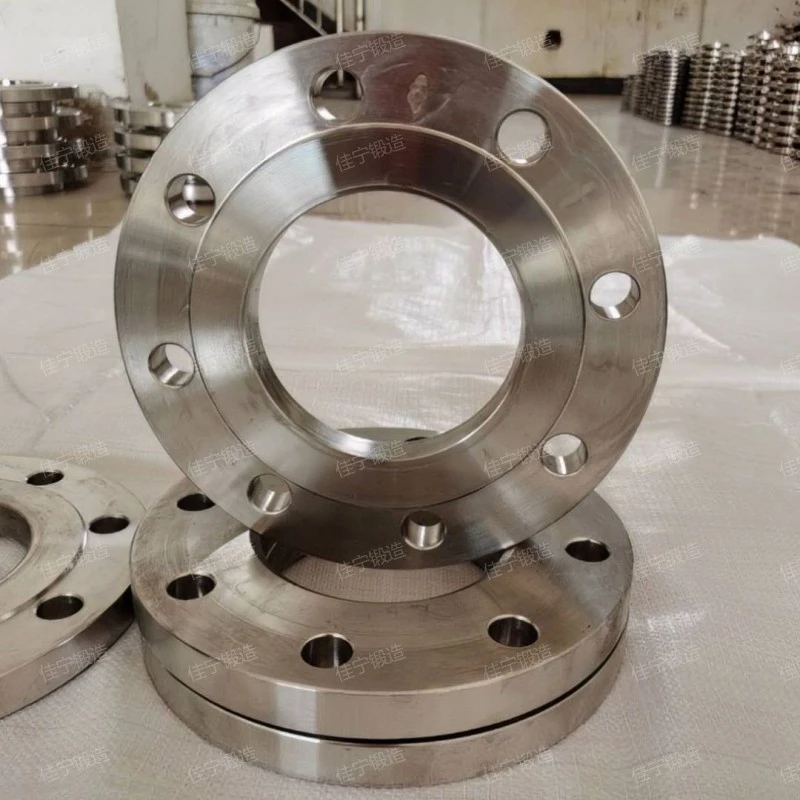

First level pressure vessel forgingsrefers to the workpiece or blank obtained by forging metal blank. In the process of forging, the metal blank is plastically deformed under the pressure of forging hammer, press and other equipment, and then its shape, size and organizational structure are changed to meet specific use requirements.,is a First level pressure vessel forgings,the product looks beautiful.,it is an ideal choice for customers to buy First level pressure vessel forgings。

First level pressure vessel forgings

2、First level pressure vessel forgings HD real picture

The First level pressure vessel forgings has a beautiful appearance and atmosphere for our customers' reference.。

First level pressure vessel forgings

Note: All the pictures in this article were taken by Jianing manufacturer.。

3、First level pressure vessel forgings performance advantage

The advantages of First level pressure vessel forgings are as follows:

- Replace other processing methods

- Perfect quality assurance system

- Eliminate internal defects

- high-intensity

- Good chemical uniformity

In some cases, First level pressure vessel forgings can replace parts produced by other processing methods (such as casting, welding, etc.), thus simplifying the production process and improving production efficiency.

In the process of First level pressure vessel forgings production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the First level pressure vessel forgings.

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the First level pressure vessel forgings.

Through forging, the internal structure of the metal is denser and the grain is refined, thus improving the strength of the material. Hot forging promotes crystallization and grain refinement, which enables materials to achieve the greatest possible strength and consistency, and reduces the variation between parts.

Forging can disperse the segregation of alloy or nonmetal and make the First level pressure vessel forgings have excellent chemical uniformity.

First level pressure vessel forgings

4、Video analysis of First level pressure vessel forgings

The following is the live video of First level pressure vessel forgings designed and produced by Jianing forging for users, from which we can see the the advantage is Forging can eliminate metal porosity and holes, and improve the mechanical properties of First level pressure vessel forgings.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of First level pressure vessel forgings can be improved.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of First level pressure vessel forgings.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal. of Jianing forgingFirst level pressure vessel forgings.。

First level pressure vessel forgings

As you can see from the live video.,Jianing forging refers to the workpiece or blank obtained by forging metal blank. In the process of forging, the metal blank is plastically deformed under the pressure of forging hammer, press and other equipment, and then its shape, size and organizational structure are changed to meet specific use requirements.。

5、How much is the First level pressure vessel forgings?

The First level pressure vessel forgings price is introduced as follows:

- technology

- Reasonable cost

- Self quality

- Service factor

- cost of production

Each customer needs different products, wants to achieve different purposes, and has different product technical design. The higher or more advanced the technical requirements, the more the product cost will be, and the price will increase with the increase of cost. On the contrary, the price will be cheaper.

When it comes to cost, I believe everyone has heard the saying "You get what you want for a price", which shows that the upfront cost of a product is directly proportional to its value. The upfront cost is high, the value is high, the quality is good, and the price is naturally high. The less the cost is, the lower the price is, and the quality is not good.

The quality of the First level pressure vessel forgings is the key factor that affects its price. The manufacturer of high-quality products has high cost in production and high product performance, which can bring higher economic benefits to customers. Because the manufacturer of high-quality products has high production investment, the manufacturer is on the high side when positioning the First level pressure vessel forgings price.

Service factors always affect the sales price of products, and high-quality service will make customers have greater satisfaction and recognition. The service factors mainly include pre-sales service, in-sales service and after-sales service. For each stage of service, our company takes the price factor into account and makes a reasonable judgment between service and price, so that the First level pressure vessel forgings price and service can meet the actual needs of customers.

The production cost determines the price. The production cost here mainly includes technology, materials, technology, manpower and other related factors, among which the technology content is high, and the cost is relatively high, but the performance will be better; The better the quality of raw materials, the greater the cost and the longer the overall life of the product; If the manufacturer has a rational manufacturing process and strict production management system, and can make full use of human and material resources, then it can reduce the waste of expenses and production costs to a great extent, and the First level pressure vessel forgings just meets this condition, so as to ensure the high-tech content and high quality of products, it can also enjoy low prices.

First level pressure vessel forgings

6、Jianing after-sales service

Perfect service: In order to improve the service quality and improve the service level, Jianing forging has set up a sound quality management department and a professional after-sales service team, so as to be highly responsible for customers and avoid their worries in the use process.。

Jianing

First level pressure vessel forgingsAfter forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、After forging, its structure and mechanical properties can be improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.,is a kind of high quality and low price First level pressure vessel forgings,the product looks atmospheric.。

Related recommendation

-

Introduction to Cover body threaded flange ring and flange advantages and features

2025-5-26 -

台车轮锻件

2024-12-10 -

Introduction to Concave convex welded steel pipe flange cover, how much is the price of the flange?

2025-5-26 -

What is a Stainless Steel Forgings? forging specifications, models, and parameters

2025-5-26 -

What is a 14 inch flange? Introduction to the advantages and characteristics of flange functions

2025-5-26 -

What is a DN150 flange ring? flange specifications, models, and parameters

2025-5-26 -

What is a 60 # forged steel parts? Introduction to the advantages and characteristics of the forging

2025-5-26 -

Introduction to Pump body forging parts, forging specifications, model parameters

2025-5-26 -

What is a Round pancake forging parts? Introduction to the advantages and characteristics of forging functions

2025-5-26 -

Introduction to Protruding flange ring, how much is the price of the flange?

2025-5-26