What is a Forged parts of mold steel disc and cake? Introduction to the advantages and characteristics of the forging

Forged parts of mold steel disc and cakeis a workpiece or blank obtained by forging and deforming a metal blank.,reliable quality。

1、Brief introduction of Forged parts of mold steel disc and cake

Forged parts of mold steel disc and cakeis a part or blank in which a metal blank is plastically deformed under pressure to obtain the required shape, size and performance.。

Forged parts of mold steel disc and cake

2、Forged parts of mold steel disc and cake characteristics

Forged parts of mold steel disc and cakefeatures include high tenacity, high-precision, Great forging flexibility, High production efficiency and high-intensity,it is widely used inpower,automobile,manufacturing industry,pressure vessel,construction machinery and other industries,is a common Forged parts of mold steel disc and cake,the product looks beautiful.,is a popular Forged parts of mold steel disc and cake。

Forged parts of mold steel disc and cake

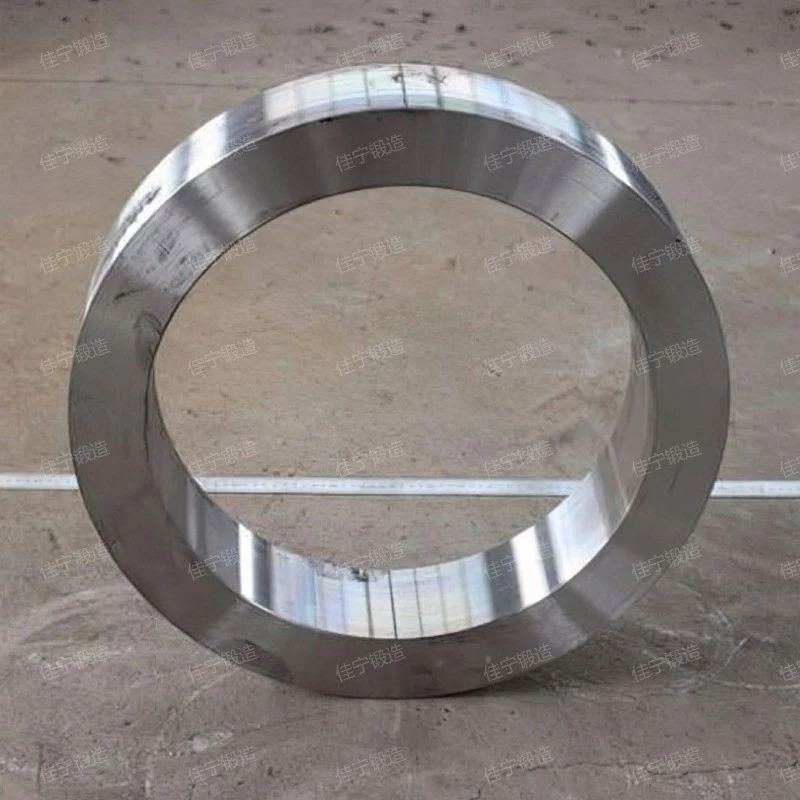

3、Forged parts of mold steel disc and cake HD real shot

High-definition pictures of Forged parts of mold steel disc and cake of different specifications and models,the product looks beautiful., reliable in quality and trustworthy.。

Forged parts of mold steel disc and cake

Note: All the pictures in this article were taken by Jianing manufacturer.。

4、Forged parts of mold steel disc and cake video

You can buy Forged parts of mold steel disc and cake according to your needs and show you Forged parts of mold steel disc and cake videos.。

Forged parts of mold steel disc and cake

As you can see from the live video.,Shanxi jianing forging co., ltd widely used in war industry, energy, metallurgy, shipping, rail traffic and other fields。

5、Introduction of advantages of Forged parts of mold steel disc and cake

The advantages of Forged parts of mold steel disc and cake are as follows:

- Improve material utilization rate

- Good fatigue resistance.

- Reduce the amount of subsequent processing

- High degree of automation

- Replace other processing methods

In the process of Forged parts of mold steel disc and cake production, through accurate blanking and forging process, the utilization rate of raw materials can be maximized and waste can be reduced.

The particle flow inside the Forged parts of mold steel disc and cake flows precisely along the contour of the part, and these continuous streamline lines are beneficial to reduce the incidence of fatigue or common faults.

The forming precision of the Forged parts of mold steel disc and cake is high, and the subsequent processing amount is relatively small, thus saving the processing cost and time.

Modern forging equipment has a high degree of automation, which can realize continuous and efficient production and greatly improve production efficiency.

In some cases, Forged parts of mold steel disc and cake can replace parts produced by other processing methods (such as casting, welding, etc.), thus simplifying the production process and improving production efficiency.

Forged parts of mold steel disc and cake

Forged parts of mold steel disc and cakeis a Forged parts of mold steel disc and cake,refers to the workpiece or blank obtained by forging metal blank.。

Related recommendation

-

Introduction to 1Cr5Mo welded flange plate, introduction to flange function advantages and characteristics

2025-5-26 -

电机轴承锻件

2024-12-10 -

What is a Square gear forgings? Introduction to the principle of gear structure

2025-5-26 -

Introduction to 316L butt welded flange plate, flange advantages, characteristics and principles

2025-5-26 -

Introduction to RF protruding flat welding flange ring, flange specifications, model parameters

2025-5-26 -

What is a Variable diameter convex surface flat welding flange cover? flange specifications, models, and parameters

2025-5-26 -

What is a 310S stainless steel threaded flange plate? Introduction to the advantages and characteristics of the flange

2025-5-26 -

What is a ABS gear? How much is the price of the gear?

2025-5-26 -

What is a Free forging of flange ring? forging specifications, models, and parameters

2025-5-26 -

Introduction to Orifice ring gear forgings and ring gear working principle

2025-5-26