Introduction to 316L butt welded flange plate, flange advantages, characteristics and principles

316L butt welded flange plateflanges, gaskets and bolts are interconnected as a group to form a detachable connection of combined sealing structure.,the product looks atmospheric.,the advantage is Based on the principle of surface sealing, the uneven parts on the sealing surface are filled with gaskets to realize effective sealing, prevent fluid leakage and ensure safe and stable operation in the production process.、Suitable connection methods can be selected according to different requirements, such as threaded connection and welding connection, so as to adapt to different working environments and technological requirements.、The manufacturing cost is relatively low, and the assembly is simple through fixing methods such as screws or nuts, so that the production efficiency is improved and the production cost is reduced.、The materials are varied, including carbon steel, stainless steel, alloy steel, etc. The appropriate materials can be selected according to the nature of the medium and working conditions to ensure the stability and corrosion resistance of the flange in different environments.、The design of the connection takes into account the factors such as disassembly, cleaning, overhaul and replacement, and has good operability, which reduces the difficulty and cost of installation.,the product looks atmospheric.,it is widely used in food processing, Pipe connection, Air conditioning and refrigeration, Pipe connection and device attachment。The following is to introduce the 316L butt welded flange plate:

1、Brief introduction of 316L butt welded flange plate

316L butt welded flange plateused for connection between pipe ends.,it is an ideal choice for customers to buy 316L butt welded flange plate。

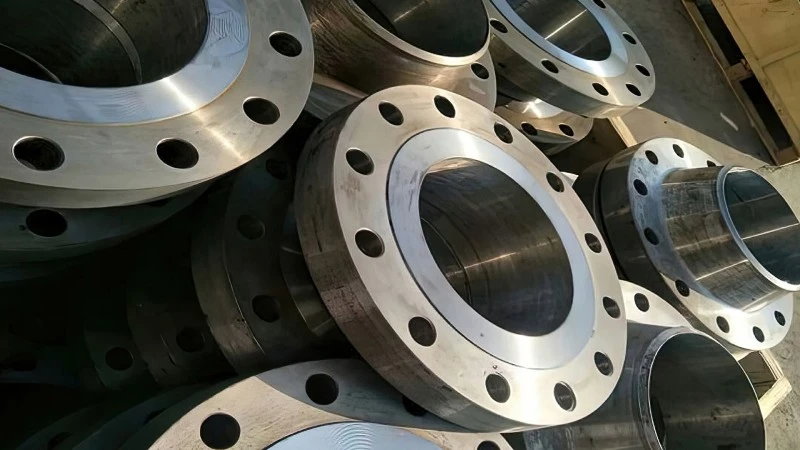

316L butt welded flange plate

2、Introduction of 316L butt welded flange plate characteristics

316L butt welded flange platethe main features are Long service life, Long service life, high-temperature resistance, Good stability and corrosion-resistant,is a disk-shaped part.,was developed and designed by Jianing forging。

316L butt welded flange plate

3、Functional advantages of 316L butt welded flange plate

316L butt welded flange plates have the following advantages.

- Good sealing performance

- zonula occludens

- Generality

- Strong bearing capacity

- economy

The 316L butt welded flange plate adopts the principle of surface sealing, and the uneven parts on the sealing surface are filled with gaskets to realize effective sealing, prevent fluid leakage and ensure safe and stable operation in the production process.

316L butt welded flange plate closely connect the two 316L butt welded flange plate through bolts and other fasteners, forming a firm mechanical connection to ensure the stable connection between pipelines and equipment.

The 316L butt welded flange plate adopts standardized design, conforms to the standards and specifications of many countries and regions, and can be used in conjunction with various brands of equipment and pipelines, thus improving the interchangeability and versatility of equipment.

The structural design of the 316L butt welded flange plate makes it have strong bearing capacity and can adapt to the needs of high-pressure working environment. Excellent performance in pipeline connection of high temperature, high pressure and corrosive media, ensuring long-term stable operation of pipeline system.

The manufacturing cost of the 316L butt welded flange plate is relatively low, and it is simple to assemble by fixing methods such as screws or nuts, which improves the production efficiency and reduces the production cost.

316L butt welded flange plate

4、316L butt welded flange plate application

316L butt welded flange plates have the following purposes.

- Convenient disassembly

- Pipe connection

- seal

- connect

- device attachment

The disassembly of the 316L butt welded flange plate is simple and convenient, and it is suitable for equipment and pipelines that need to be cleaned, overhauled or replaced frequently, which is convenient for maintenance personnel to maintain.

Used for conveying various liquids, gases and solid fluids, such as [commodity industry] and other fields.

Through the principle of surface sealing, it is ensured that the joint will not leak air, water or oil, thus ensuring the safe and reliable operation of the fluid conveying system.

316L butt welded flange plate can closely connect different pipelines, valves, pumps and containers to form a complete fluid conveying system.

Connect all kinds of equipment and machinery, such as engines, pumps, compressors, heat exchangers, air conditioning equipment, etc.

316L butt welded flange plate

5、Introduction of 316L butt welded flange plate characteristics

316L butt welded flange plateHigh reliability,Long service life,high-temperature resistance,corrosion-resistant,High reliability,is a 316L butt welded flange plate,Widely used in support, Pipe connection, connect, device attachment and seal。

316L butt welded flange plate

316L butt welded flange platethe advantage is Simple and convenient disassembly, suitable for equipment and pipelines that need to be cleaned, overhauled or replaced frequently, convenient for maintenance personnel to maintain, and reducing downtime and maintenance cost.、The two flanges are tightly connected by bolts and other fasteners to form a firm mechanical connection, thus ensuring the stable connection between the pipeline and the equipment.、Simple and convenient disassembly, suitable for equipment and pipelines that need to be cleaned, overhauled or replaced frequently, convenient for maintenance personnel to maintain, and reducing downtime and maintenance cost.、The materials are varied, including carbon steel, stainless steel, alloy steel, etc. The appropriate materials can be selected according to the nature of the medium and working conditions to ensure the stability and corrosion resistance of the flange in different environments.、The structural design makes it have strong bearing capacity and can adapt to the needs of high-pressure working environment. Excellent performance in pipeline connection of high temperature, high pressure and corrosive media, ensuring long-term stable operation of pipeline system.,is a disc-shaped part, which is mainly used to connect pipes, valves, pumps and containers.,the product looks beautiful.。

Related recommendation

-

Introduction to 40Cr forging, introduction to forging advantages and characteristics

2025-5-26 -

S2工具钢锻件

2024-12-10 -

Introduction to 40Cr forged shaft parts, advantages, characteristics and principles of forging

2025-5-26 -

Introduction to Flat welding lining ring flange, introduction to flange function advantages and characteristics

2025-5-26 -

Introduction to PN160 flange and flange working principle

2025-5-26 -

Introduction to National Army Standard Free Forging and forging advantages and features

2025-5-26 -

What is a Orifice plate welded flange ring? Introduction to the principle of flange structure

2025-5-26 -

Introduction to Flat welding docking flange plate, advantages, characteristics and principles of flange

2025-5-26 -

What is a High strength steel forged parts? forging specifications, models, and parameters

2025-5-26 -

Introduction to Oil cylinder bottom forging, introduction to forging advantages and characteristics

2025-5-26