Introduction to Nickel based alloy forged parts, advantages, characteristics and principles of forging

Nickel based alloy forged partsrefers to the workpiece or blank obtained by forging metal blank.,the product looks atmospheric.,the main features are high-intensity, Can bear large impact force or heavy load., Good mechanical properties, high tenacity and Great forging flexibility,is designed by Jianing with advanced technology。

1、Brief introduction of Nickel based alloy forged parts

Nickel based alloy forged partsrefers to the workpiece or blank obtained by forging metal blank.,the product looks beautiful.。

Nickel based alloy forged parts

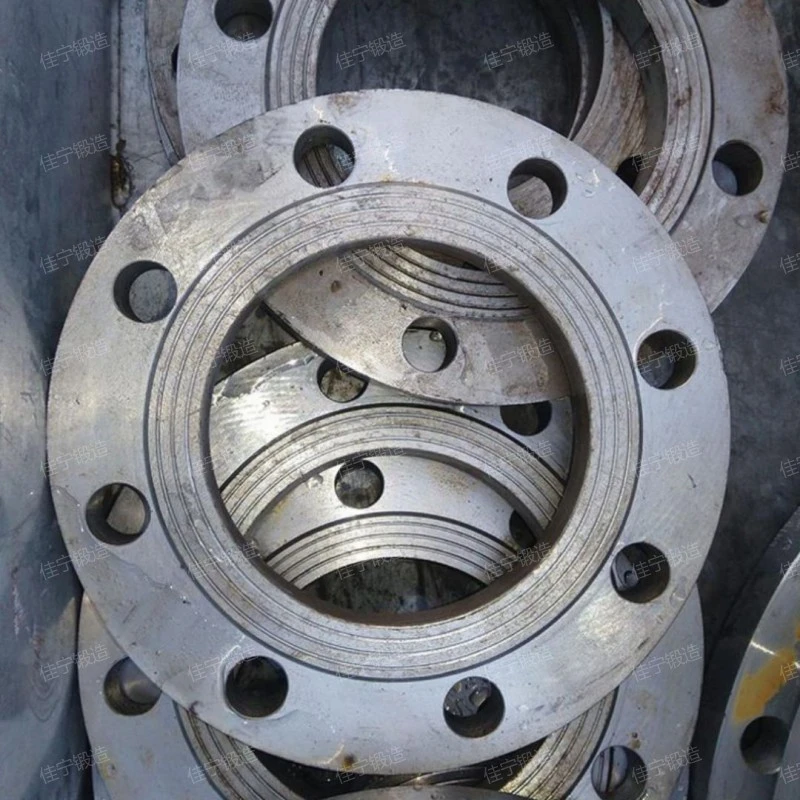

2、On-site real shot of Nickel based alloy forged parts

Jianing forging Nickel based alloy forged parts manufacturers, a variety of series of Nickel based alloy forged parts with high-definition pictures at a glance, showing the product style, for the majority of users to choose at will.。

Nickel based alloy forged parts

Note: All the pictures in this article were taken by Jianing manufacturer.。

3、Nickel based alloy forged parts video detail

You can buy Nickel based alloy forged parts according to your needs and show you product videos.。

Nickel based alloy forged parts

As you can see from the live video.,Shanxi jianing forging co., ltd is a workpiece or blank obtained by forging and deforming a metal blank.。

4、Nickel based alloy forged parts performance advantage

The advantages of Nickel based alloy forged parts are as follows:

- Improve material utilization rate

- high tenacity

- High dimensional accuracy

- high-intensity

- Perfect quality assurance system

In the process of Nickel based alloy forged parts production, through accurate blanking and forging process, the utilization rate of raw materials can be maximized and waste can be reduced.

The fiber structure of the Nickel based alloy forged parts is reasonably distributed, which improves the toughness of the material and enables the Nickel based alloy forged parts to bear greater impact force and alternating stress.

In the forging process of Nickel based alloy forged parts, high dimensional accuracy and shape accuracy can be obtained through the precise forming of dies.

Through forging, the internal structure of the metal is denser and the grain is refined, thus improving the strength of the material. Hot forging promotes crystallization and grain refinement, which enables materials to achieve the greatest possible strength and consistency, and reduces the variation between parts.

In the process of Nickel based alloy forged parts production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the Nickel based alloy forged parts.

Nickel based alloy forged parts

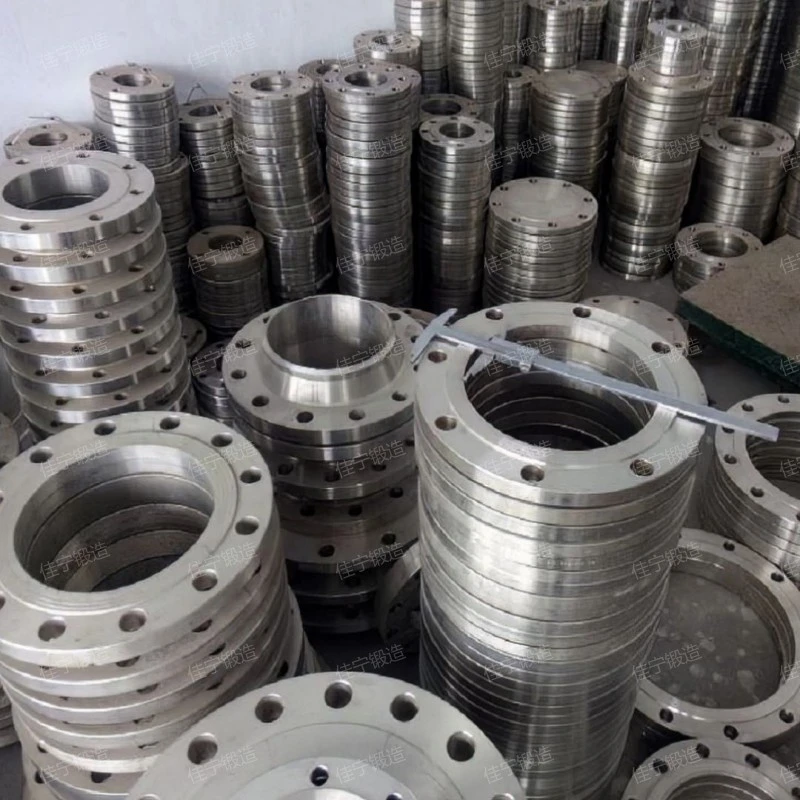

5、Nickel based alloy forged parts HD picture

High-definition pictures for various Nickel based alloy forged parts, panoramic display,the product looks atmospheric., reliable in quality and trustworthy.。

Nickel based alloy forged parts

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

6、How much is the Nickel based alloy forged parts?

The Nickel based alloy forged parts price is introduced as follows:

- brand

- Self quality

- Configuration difference

- Manufacturer's strength

- geographical position

Different brands of products in the same series have more or less differences in product prices, and different brands of Nickel based alloy forged parts have more or less differences in price.

Quality is an important and fundamental factor that affects the price of Nickel based alloy forged parts. In the final analysis, its price depends on its quality. Usually, Nickel based alloy forged parts with better quality will cost more, and such products have better effects, longer service life and more advanced technology. A Nickel based alloy forged parts with a relatively general quality will cost less, have a shorter service life and have a relatively general use effect.

There is a direct connection between configuration and specifications. Generally speaking, with different specifications, its configuration scheme will be different, and the selection of products' materials and parts will be different, so the sales price of products will be different. It is not difficult to see that the configuration and price of Nickel based alloy forged parts are closely related. Jianing forging has comprehensively measured the configuration and sales price of products when designing Nickel based alloy forged parts, which not only ensures that the functions of products can meet the actual needs of customers, but also can be in terms of price.

There are many Nickel based alloy forged parts manufacturers on the market. Different manufacturers spend different costs, such as material costs, labor costs, manufacturing costs, etc., and their products are quoted differently.

Geographical location also has a certain influence on the formulation of price, because there is a close relationship between geographical location and transportation cost. Generally, the price of places with superior geographical location will be more fair, which is lower than that of those remote cities. Jianing address:Shanxi, where the traffic is very developed and convenient, provides a series of conveniences for the distribution of products to a great extent.

Nickel based alloy forged parts

Nickel based alloy forged partsBy forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Nickel based alloy forged parts can be improved.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Nickel based alloy forged parts.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.,forging equipment is used to apply external force to the blank, so that the metal blank is plastically deformed, so as to obtain forgings with required geometric shape and quality.。

Related recommendation

-

Introduction to Flange ring of protruding pipe, flange advantages, characteristics and principles

2025-5-26 -

Introduction to SAE butt welding flange, introduction to flange advantages and characteristics

2025-5-26 -

What is a Shaft head free forging? Introduction to the Working Principle of forging

2025-5-26 -

What is a PN25 flange ring? flange specifications, models, and parameters

2025-5-26 -

Introduction to SAE blind plate, introduction to blind plate function advantages and characteristics

2025-5-26 -

What is a High pressure oil cylinder forging parts? How much is the price of the forging?

2025-5-26 -

Introduction to Flat welded flange cover with different necks and flange advantages and features

2025-5-26 -

What is a Quick plug flange? Introduction to the principle of flange structure

2025-5-26 -

Introduction to Chemical Department flat welding flange, how much is the price of the flange?

2025-5-26 -

Introduction to Ring groove sealing face welding flange, introduction to flange function advantages and characteristics

2025-5-26