Introduction to 4140 alloy forgings, forging specifications, model parameters

4140 alloy forgingsrefers to the workpiece or blank obtained by forging metal blank.,Can bear large impact force or heavy load.,High production efficiency,Good mechanical properties,Save raw materials,Great forging flexibility,the advantage is After forging, its structure and mechanical properties can be improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of 4140 alloy forgings.、After forging, its structure and mechanical properties can be improved.,support customization。

1、Brief introduction of 4140 alloy forgings

4140 alloy forgingsforging equipment is used to apply external force to the blank, so that the metal blank is plastically deformed, so as to obtain forgings with required geometric shape and quality.。

4140 alloy forgings

2、Introduction of advantages of 4140 alloy forgings

The advantages of 4140 alloy forgings are as follows:

- Optimizing structural design

- Improve material utilization rate

- Eliminate internal defects

- Improve material utilization rate

- high-intensity

On the premise of ensuring the design strength, through reasonable structural design, the 4140 alloy forgings can be lighter than the casting, thus reducing the overall weight of the machine or equipment and reducing energy consumption and cost.

In the process of 4140 alloy forgings production, through accurate blanking and forging process, the utilization rate of raw materials can be maximized and waste can be reduced.

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the 4140 alloy forgings.

In the process of 4140 alloy forgings production, through accurate blanking and forging process, the utilization rate of raw materials can be maximized and waste can be reduced.

Through forging, the internal structure of the metal is denser and the grain is refined, thus improving the strength of the material. Hot forging promotes crystallization and grain refinement, which enables materials to achieve the greatest possible strength and consistency, and reduces the variation between parts.

4140 alloy forgings

3、Introduction of 4140 alloy forgings characteristics

4140 alloy forgingsit has the characteristics of high-intensity, High productivity, Good anti-fatigue performance, high-precision and high tenacity,is a kind of 4140 alloy forgings manufactured by Jianing forging。

4140 alloy forgings

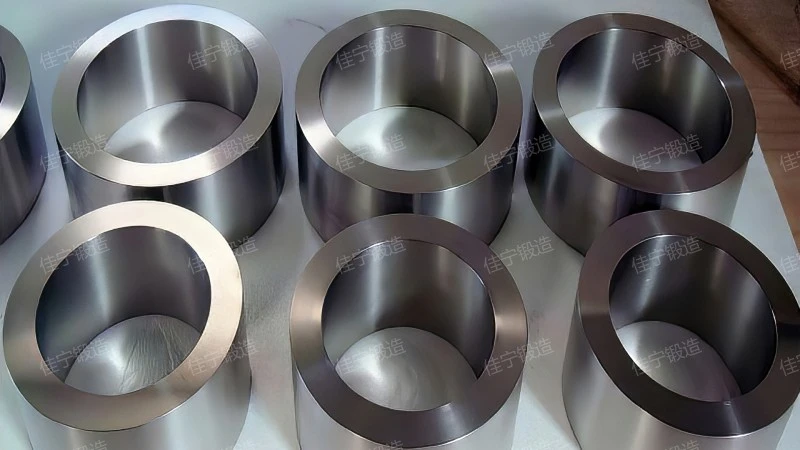

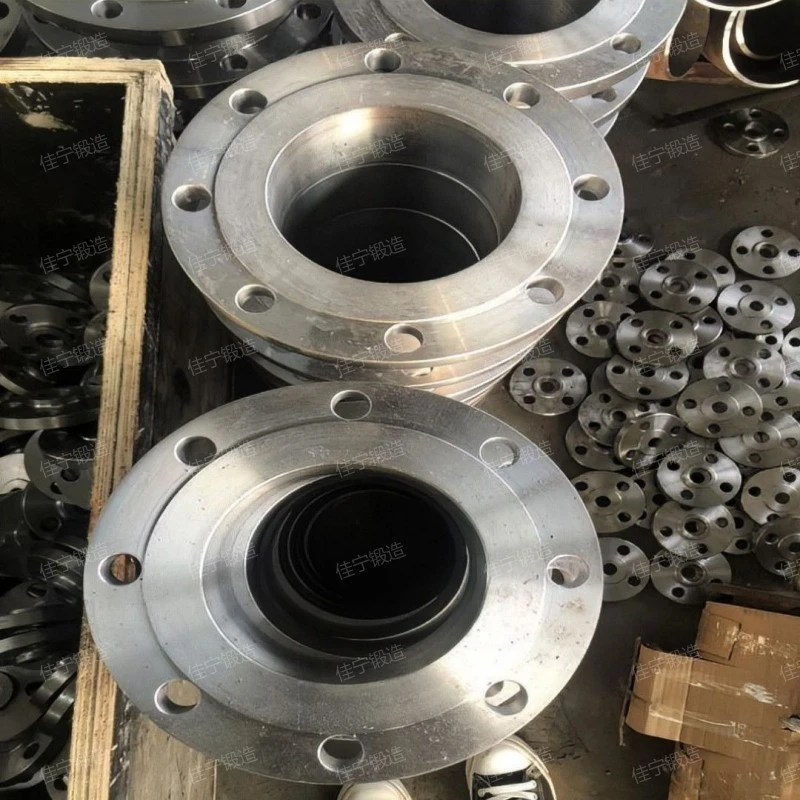

4、4140 alloy forgings work site real shot

Display of 4140 alloy forgings with different specifications and models。

4140 alloy forgings

Note: All the pictures in this article were taken by Jianing manufacturer.。

5、4140 alloy forgings working site

On-site aerial photography of 4140 alloy forgings。

4140 alloy forgings

As you can see from the live video.,Jianing the main features are Light weight, Great forging flexibility, high-intensity, high-precision and Save raw materials。

6、How much is the 4140 alloy forgings?

The 4140 alloy forgings price is introduced as follows:

- Model size

- select a qualified person

- Different regions

- Manufacturer scale

- quality

The quotation of the same series of 4140 alloy forgings with different specifications and models is different. The larger the model, the higher the product cost and the higher the overall quotation. On the contrary, the smaller the model, the lower the product cost and the lower the overall quotation.

The raw materials used by manufacturers of different products will definitely be different. Some manufacturers use good raw materials for processing, and the cost of producing and manufacturing products is definitely high. If the quality of products produced by manufacturers is not guaranteed and the materials used are not very good, then the production cost of products will be low, and the price will be very low.

Geographical location also has a certain influence on the formulation of price, because there is a close relationship between geographical location and transportation cost. Generally, the price of places with superior geographical location will be more fair, which is lower than that of those remote cities. Jianing forging located in Shanxi Xinzhou., where the traffic is very developed and convenient, provides a series of conveniences for the distribution of products to a great extent.

Although there are many manufacturers of products in Shanxi, there are certain differences in the scale and strength of each manufacturer. Some manufacturers are large in scale and strength, some are small in scale, and some manufacturers do not have their own production workshops and belong to middlemen. Relatively speaking, the prices of products formulated by middlemen are higher.

Quality is one of the fundamental and important factors that affect the price. Usually, the better the quality of the 4140 alloy forgings, the higher its price, and the quality is mainly affected by the manufacturing process, raw material materials, workers' experience and other factors. Therefore, if customers want to buy products with better quality, they can conduct on-the-spot visits to the product manufacturers to learn more about the scale, manufacturing process and production capacity of the manufacturers, so as to comprehensively judge the quality of the products.

4140 alloy forgings

4140 alloy forgingsis a part or blank in which a metal blank is plastically deformed under pressure to obtain the required shape, size and performance.,Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of 4140 alloy forgings can be improved.。

Related recommendation

-

What is a 20MnMo forged parts? Introduction to the Working Principle of forging

2025-5-26 -

石油无磁扶正器锻件

2024-12-10 -

What is a Plate type flat welding flat flange? flange specifications, models, and parameters

2025-5-26 -

Introduction to DN1900 flange cover, flange advantages, characteristics and principles

2025-5-26 -

What is a 316L ring groove flange? Introduction to the advantages and characteristics of the flange

2025-5-26 -

What is a Chromium molybdenum vanadium steel valve forging parts? Introduction to the Working Principle of forging

2025-5-26 -

Introduction to DN2200 flange, introduction to flange advantages and characteristics

2025-5-26 -

Introduction to Flat welding groove flange plate and flange advantages and features

2025-5-26 -

Introduction to Carbon steel threaded protruding flange ring, flange advantages, characteristics and principles

2025-5-26 -

Introduction to Disk type forgings, how much is the price of the forging?

2025-5-26