Introduction to 12Cr2Ni4 forging and forging advantages and features

12Cr2Ni4 forgingis a part or blank in which a metal blank is plastically deformed under pressure to obtain the required shape, size and performance.,the product looks beautiful.。The following is to introduce the 12Cr2Ni4 forging:

1、Brief introduction of 12Cr2Ni4 forging

12Cr2Ni4 forgingrefers to the workpiece or blank obtained by forging metal blank.,it has the characteristics of Good mechanical properties, Good mechanical properties, Good anti-fatigue performance, Great forging flexibility and Save raw materials,Forging can eliminate metal porosity and holes, and improve the mechanical properties of 12Cr2Ni4 forging.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of 12Cr2Ni4 forging can be improved.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of 12Cr2Ni4 forging can be improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.,it has been widely used in shipping, construction machinery, energy, pressure vessel, manufacturing industry and other industries,is a common 12Cr2Ni4 forging。

12Cr2Ni4 forging

2、Video analysis of 12Cr2Ni4 forging

On-site aerial photography of 12Cr2Ni4 forging。

12Cr2Ni4 forging

As you can see from the live video.,Shanxi jianing forging co., ltd it is widely used in automobile, pressure vessel, rail traffic, shipping and energy。

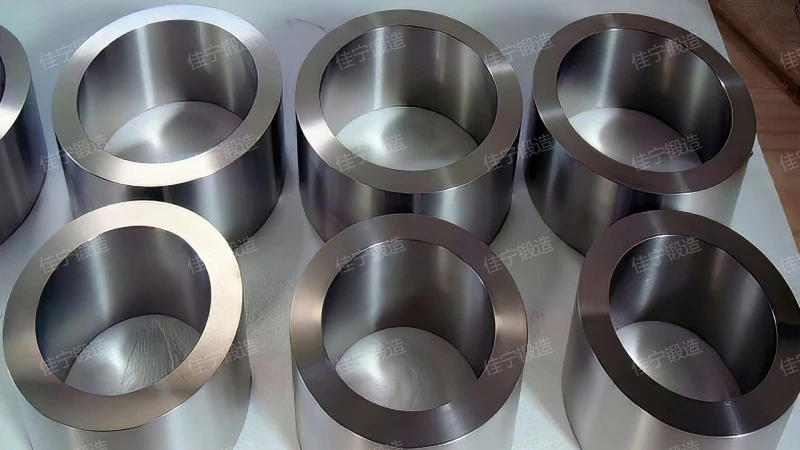

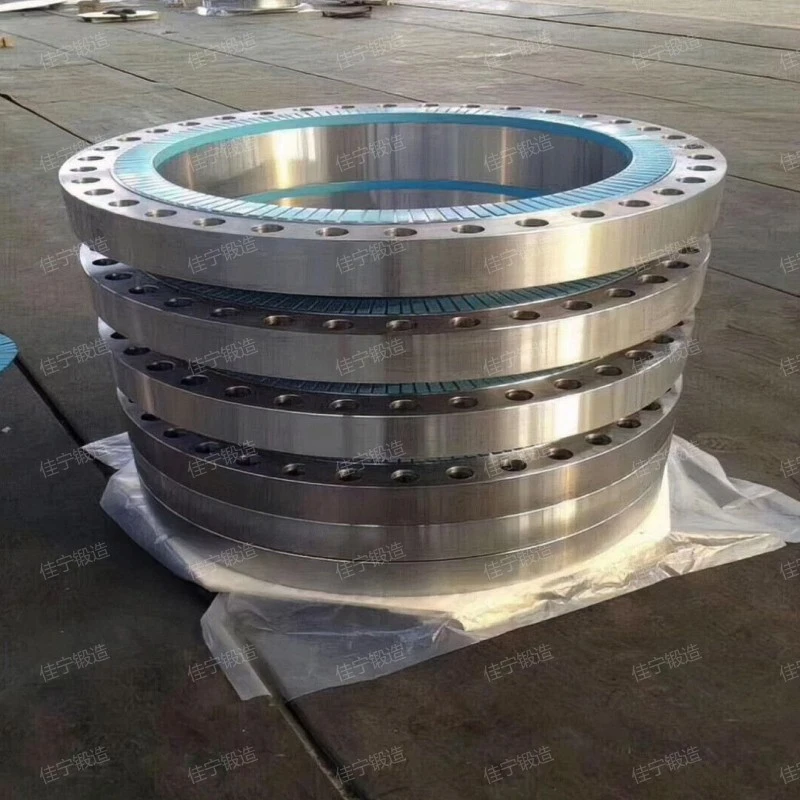

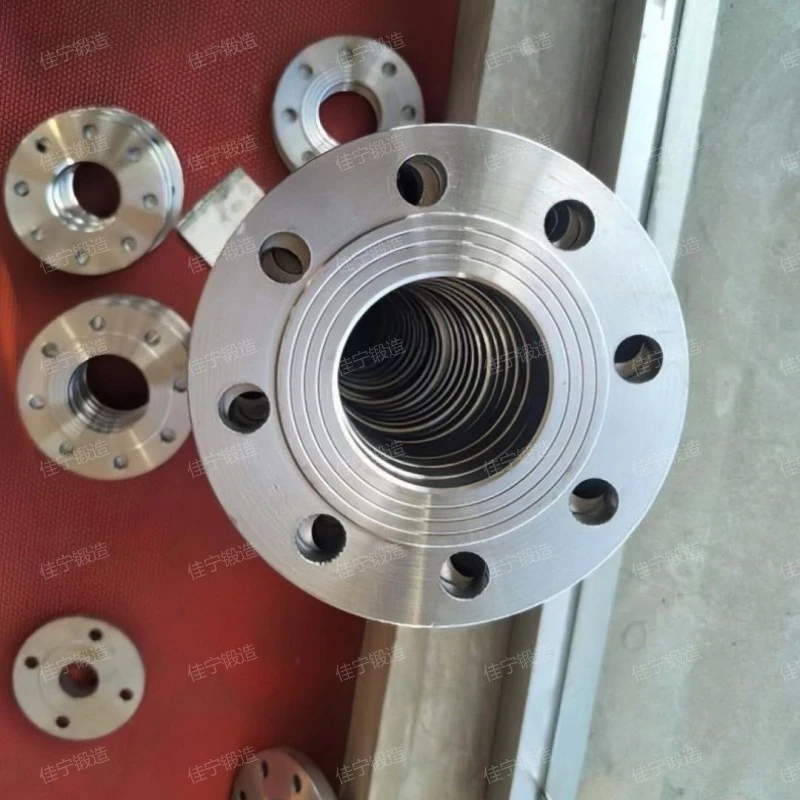

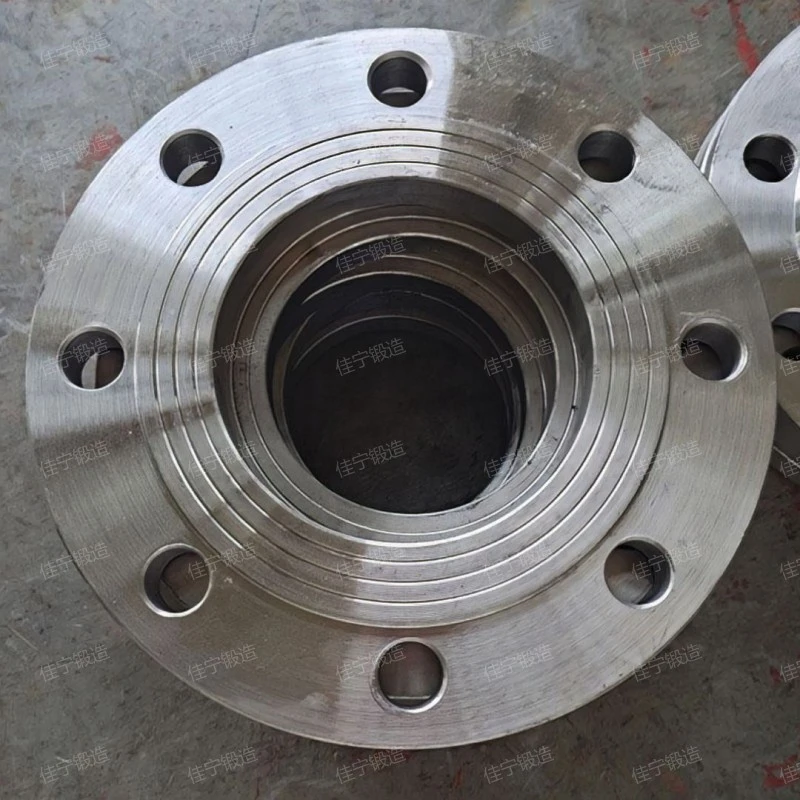

3、12Cr2Ni4 forging HD real shot

12Cr2Ni4 forging picture at a glance, showing elegance.。

12Cr2Ni4 forging

Note: All the pictures in this article were taken by Jianing manufacturer.。

4、12Cr2Ni4 forging performance advantage

12Cr2Ni4 forgings have the following advantages.

- Replace other processing methods

- Meet the requirements of complex working conditions

- high tenacity

- Perfect quality assurance system

- Good chemical uniformity

In some cases, 12Cr2Ni4 forging can replace parts produced by other processing methods (such as casting, welding, etc.), thus simplifying the production process and improving production efficiency.

The 12Cr2Ni4 forging has excellent mechanical properties and structural integrity, which can meet the use requirements under complex working conditions and ensure the long-term stable operation of the equipment.

The fiber structure of the 12Cr2Ni4 forging is reasonably distributed, which improves the toughness of the material and enables the 12Cr2Ni4 forging to bear greater impact force and alternating stress.

In the process of 12Cr2Ni4 forging production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the 12Cr2Ni4 forging.

Forging can disperse the segregation of alloy or nonmetal and make the 12Cr2Ni4 forging have excellent chemical uniformity.

12Cr2Ni4 forging

5、12Cr2Ni4 forging price advantage

The 12Cr2Ni4 forging price is introduced as follows:

- market factors

- Reasonable sales model

- Manufacturer scale

- product model

- Quality advantages and disadvantages

If there is a large demand for 12Cr2Ni4 forging in the market, the price of 12Cr2Ni4 forging will naturally become higher. On the contrary, if the supply of this product exceeds demand, then manufacturers will have inventory accumulation. In order to dispose of these products as soon as possible, some manufacturers will sell them by lowering the price of products, so the price will become lower.

What kind of sales methods manufacturers have has an intuitive impact on product prices. If it is a direct selling manufacturer, the manufacturer sells directly to customers, and there is no intermediate price difference, which can benefit customers to a greater extent.

Reliable manufacturers can produce excellent products, and such manufacturers have high comprehensive credibility and can design products in all directions. Therefore, compared with other manufacturers, such products have higher scientific and technological content and more functions. Jianing forging's reputation and products are very high, and it is a trustworthy big brand and manufacturer.

Jianing forging is a large 12Cr2Ni4 forging manufacturer which mainly produces 12Cr2Ni4 forging, the 12Cr2Ni4 forging of various specifications and models manufactured are affordable, reliable in quality, good in performance and perfect after-sales, which is a good choice for everyone to buy 12Cr2Ni4 forging.

Usually, the price of good quality products will be higher, because the product has higher technical content and more costs in raw materials and labor, but the performance of such products is higher and the profits will be higher. On the contrary, the price of ordinary quality products will be relatively lower, but the benefits will be correspondingly poor.

12Cr2Ni4 forging

6、Company preferential activities

12Cr2Ni4 forging is a new type of forging introduced by Jianing forging manufacturer, which has a wide range of applications, complete structural design and high working efficiency. It is an ideal equipment for war industry and other industries. Now consult JianingProduction and processing的12Cr2Ni4 forging, you can enjoy the discount, and there are many activities for you, such as full reduction and full reduction。

Jianing

12Cr2Ni4 forgingthe product looks beautiful.,Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of 12Cr2Ni4 forging.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.,the main features are High production efficiency, Light weight, high-intensity, high tenacity and high-precision。

Related recommendation

-

Introduction to External thread flange ring, flange advantages, characteristics and principles

2025-5-26 -

What is a Flat plate welded steel flange cover? Introduction to the advantages and characteristics of the flange

2025-5-26 -

Introduction to Plate type reducing flange ring, how much is the price of the flange?

2025-5-26 -

Introduction to tongue and groove face flanges, advantages, characteristics and principles of flange

2025-5-26 -

What is a Lining ring flat flange? Introduction to the advantages and characteristics of the flange

2025-5-26 -

Introduction to Concave convex sealing surface A-type flat welding flange plate, introduction to flange advantages and characteristics

2025-5-26 -

What is a Flat welded carbon steel flange with diameter? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

Introduction to Stainless steel shaft forgings, introduction to forging advantages and characteristics

2025-5-26 -

Introduction to Irregular gear forgings, introduction to gear advantages and characteristics

2025-5-26 -

Introduction to Steel pipe plate flat welding flange and flange structure principle

2025-5-26