Introduction to Corrosion resistant alloy forgings, how much is the price of the forging?

Corrosion resistant alloy forgingsrefers to the workpiece or blank obtained by forging metal blank.,the product looks beautiful.,features include Light weight, Great forging flexibility, high-intensity, high-precision and High production efficiency,is a Corrosion resistant alloy forgings newly developed by Jianing forging。The following is to introduce the Corrosion resistant alloy forgings:

1、Brief introduction of Corrosion resistant alloy forgings

Corrosion resistant alloy forgingsforging equipment is used to apply external force to the blank, so that the metal blank is plastically deformed, so as to obtain forgings with required geometric shape and quality.,Forging can eliminate metal porosity and holes, and improve the mechanical properties of Corrosion resistant alloy forgings.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Corrosion resistant alloy forgings can be improved.,it has been widely used in manufacturing industry, power, metallurgy, power, rail traffic and other industries。

Corrosion resistant alloy forgings

2、Corrosion resistant alloy forgings video live broadcast

On-site aerial photography of Corrosion resistant alloy forgings。

Corrosion resistant alloy forgings

As you can see from the live video.,Jianing the forging machine is used to exert pressure on the blank.。

3、Introduction of Corrosion resistant alloy forgings characteristics

Corrosion resistant alloy forgingsthe main features are high tenacity, Good anti-fatigue performance, Save raw materials, High productivity and Good mechanical properties,is a workpiece or blank obtained by forging and deforming a metal blank.,widely used inautomobile,shipping,automobile,construction machinery,war industry and other industries,is a kind of high quality and low price Corrosion resistant alloy forgings,is designed by Jianing with advanced technology。

Corrosion resistant alloy forgings

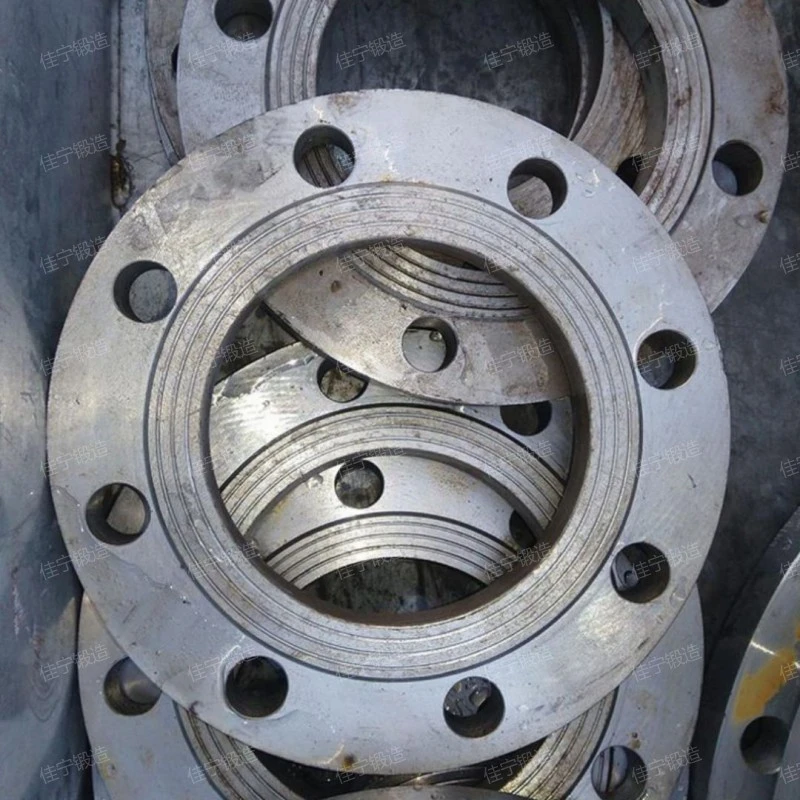

4、Corrosion resistant alloy forgings real beat

Corrosion resistant alloy forgings high-definition picture display, all-round shooting without dead ends, for our customers to visit.。

Corrosion resistant alloy forgings

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

5、Corrosion resistant alloy forgings price concessions

The Corrosion resistant alloy forgings price is introduced as follows:

- Manufacturer scale

- Different regions

- marketing channel

- Cost input

- select a qualified person

Direct selling by manufacturers and sales by middlemen will also affect product prices. There are not too many links among direct selling products, so the cost required by manufacturers is low, and the price of Corrosion resistant alloy forgings is low. Customers can also put products into production in advance. On the contrary, when purchasing products from middlemen, there are not only many links, but also the price of Corrosion resistant alloy forgings is much higher, so customers should choose products directly sold by manufacturers when purchasing.

Geographical location also has a certain influence on the formulation of price, because there is a close relationship between geographical location and transportation cost. Generally, the price of places with superior geographical location will be more fair, which is lower than that of those remote cities. Jianing address:Xinzhou, where the traffic is very developed and convenient, provides a series of conveniences for the distribution of products to a great extent.

Direct-selling manufacturers are cheaper than second-and third-tier dealers because the former earns the difference without going through middlemen; Online sales are cheaper than offline sales, because you need to invest in store fees, employee fees and other related expenses in the later stage; Close-distance sales are cheaper than long-distance sales because the latter consumes a lot of transportation costs.

When it comes to cost, I believe everyone has heard the saying "You get what you want for a price", which shows that the upfront cost of a product is directly proportional to its value. The upfront cost is high, the value is high, the quality is good, and the price is naturally high. The less the cost is, the lower the price is, and the quality is not good.

The higher the cost of materials, the higher the price will be. In the process of purchasing products, users need to make a detailed understanding of the materials selected for products.

Corrosion resistant alloy forgings

6、Jianing company discount

Corrosion resistant alloy forgings is a new type of forging introduced by Shanxi jianing forging co., ltd manufacturer, which has a wide range of applications, complete structural design and high working efficiency. It is an ideal equipment for war industry and other industries. Now consult Jianing forgingCorrosion resistant alloy forgings, you can enjoy the discount, and there are many activities for you, such as full reduction and full reduction。

Jianing forging

Corrosion resistant alloy forgingsit has the characteristics of Can bear large impact force or heavy load., Light weight, Save raw materials, Good mechanical properties and Good anti-fatigue performance,the advantage is Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.,widely used in energy, construction machinery, shipping, manufacturing industry, pressure vessel and other fields。

Related recommendation

-

Introduction to Pipeline butt welding flange ring, introduction to flange advantages and characteristics

2025-5-26 -

Introduction to Integral flat welding flange cover and flange structure principle

2025-5-26 -

Introduction to High pressure valve forging parts and forging structure principle

2025-5-26 -

What is a Carbon steel threaded pipe with matching flange cover? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

What is a 65Mn forging? Introduction to the advantages and characteristics of the forging

2025-5-26 -

Introduction to Forged parts of reducer shaft, introduction to forging function advantages and characteristics

2025-5-26 -

What is a Flat welding flange cover on the ring connection surface? Introduction to the principle of flange structure

2025-5-26 -

Introduction to Stainless steel pipe butt welded flange, advantages, characteristics and principles of flange

2025-5-26 -

Introduction to Petroleum steel flat welding flange plate, advantages, characteristics and principles of flange

2025-5-26 -

Introduction to Buckle flange ring, introduction to flange function advantages and characteristics

2025-5-26