Introduction to 42CrMo4 forged parts, introduction to forging advantages and characteristics

42CrMo4 forged partsrefers to the workpiece or blank obtained by forging metal blank.,the product looks beautiful.,is a 42CrMo4 forged parts,Forging can eliminate metal porosity and holes, and improve the mechanical properties of 42CrMo4 forged parts.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of 42CrMo4 forged parts can be improved.、After forging, its structure and mechanical properties can be improved.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.,The price is more affordable,reliable quality。The following is to introduce the 42CrMo4 forged parts:

1、Brief introduction of 42CrMo4 forged parts

42CrMo4 forged partsis a part or blank in which a metal blank is plastically deformed under pressure to obtain the required shape, size and performance.,it has the characteristics of Good mechanical properties, High productivity, Good anti-fatigue performance, high-precision and Can bear large impact force or heavy load.。

42CrMo4 forged parts

2、Introduction of 42CrMo4 forged parts characteristics

42CrMo4 forged partsHigh production efficiency,Great forging flexibility,Save raw materials,Good mechanical properties,Save raw materials。

42CrMo4 forged parts

3、42CrMo4 forged parts advantage

The advantages of 42CrMo4 forged parts are as follows:

- Optimizing structural design

- Perfect quality assurance system

- High degree of automation

- Improve material utilization rate

- Eliminate internal defects

On the premise of ensuring the design strength, through reasonable structural design, the 42CrMo4 forged parts can be lighter than the casting, thus reducing the overall weight of the machine or equipment and reducing energy consumption and cost.

In the process of 42CrMo4 forged parts production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the 42CrMo4 forged parts.

Modern forging equipment has a high degree of automation, which can realize continuous and efficient production and greatly improve production efficiency.

In the process of 42CrMo4 forged parts production, through accurate blanking and forging process, the utilization rate of raw materials can be maximized and waste can be reduced.

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the 42CrMo4 forged parts.

42CrMo4 forged parts

4、42CrMo4 forged parts characteristics

42CrMo4 forged partsfeatures include High productivity, High production efficiency, high tenacity, high-intensity and Good anti-fatigue performance,refers to the workpiece or blank obtained by forging metal blank.,Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of 42CrMo4 forged parts.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.,is a kind of high quality and low price 42CrMo4 forged parts,it is widely used in energy, manufacturing industry, metallurgy, rail traffic, shipping and other industries。

42CrMo4 forged parts

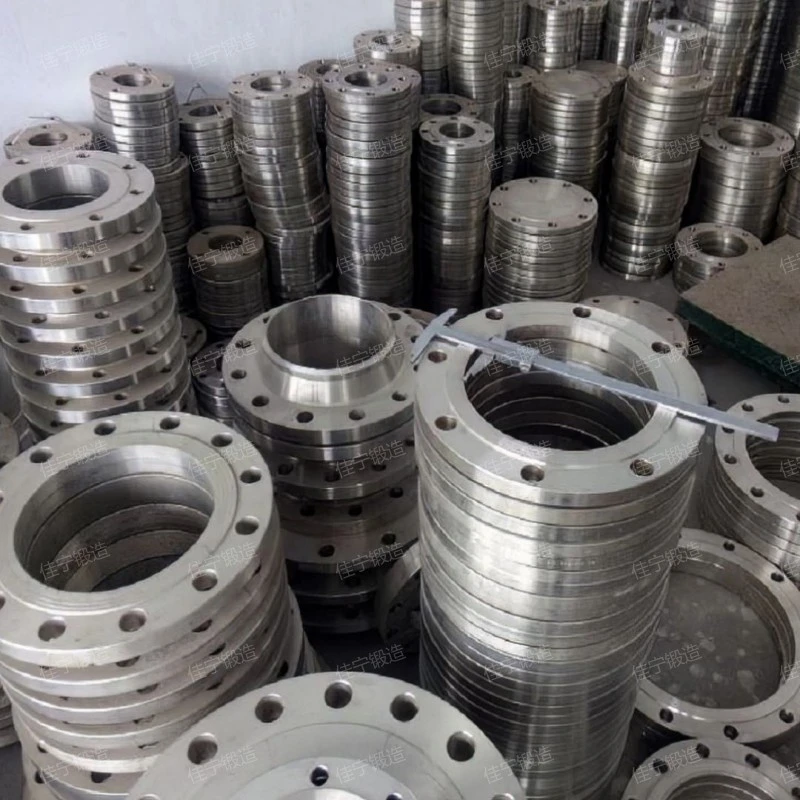

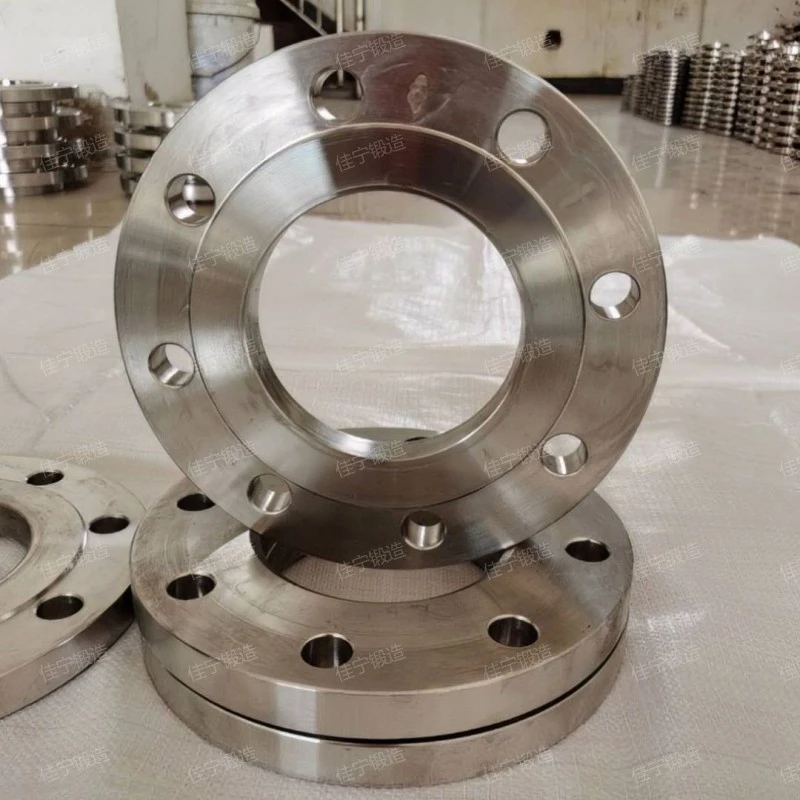

5、42CrMo4 forged parts HD picture real shot

HD pictures of 42CrMo4 forged parts of different specifications and models。

42CrMo4 forged parts

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

6、42CrMo4 forged parts quotation

The 42CrMo4 forged parts price is introduced as follows:

- Proper management mode

- Brand strength

- market factors

- select a qualified person

- Model specification

Jianing 42CrMo4 forged parts manufacturer is a large 42CrMo4 forged partsmanufacturer, the manufacturer produces and sells products directly to customers, without the influence of the price difference between middlemen. The market price of the manufacturer's products is the ex-factory price, and the 42CrMo4 forged parts price is also low.

At present, there are various brands of 42CrMo4 forged parts in Shanxi Xinzhou. The performance, quality and after-sales of products under different brands are different, and the prices of 42CrMo4 forged parts are different.

Market change is the main factor that affects the price level. Because of the instability and uncertainty of the market, the sales price of 42CrMo4 forged parts will fluctuate greatly, and the market changes are various.

The higher the cost of materials, the higher the price will be. In the process of purchasing products, users need to make a detailed understanding of the materials selected for products.

Different models will have different specifications, which will lead to greater differences in the comprehensive configuration of products, which will also lead to greater changes in prices.

42CrMo4 forged parts

42CrMo4 forged partsCan bear large impact force or heavy load.,Light weight,Great forging flexibility,high-precision,Good mechanical properties,widely used inrail traffic,construction machinery,construction machinery,power,pressure vessel and other industries,the product looks atmospheric.。

Related recommendation

-

Introduction to 2-inch flange ring and flange advantages and features

2025-5-26 -

船用螺旋桨轴锻件

2024-12-10 -

Introduction to Reducing flat welding flange and flange structure principle

2025-5-26 -

What is a gear? gear specifications, models, and parameters

2025-5-26 -

Introduction to Ear flange ring, flange advantages, characteristics and principles

2025-5-26 -

不锈钢端部转环锻件

2024-12-10 -

What is a DN3200 flange plate? Introduction to the Working Principle of flange

2025-5-26 -

Introduction to Pipeline variable diameter flange ring and flange structure principle

2025-5-26 -

What is a Type A flat welded container flange? Introduction to the Working Principle of flange

2025-5-26 -

Introduction to DN850 flange cover, how much is the price of the flange?

2025-5-26