Introduction to 15CrMoV forged parts and forging structure principle

15CrMoV forged partsplastic deformation is made to obtain forgings with certain shapes and mechanical properties.,widely used in construction machinery, automobile, pressure vessel, energy, shipping and other fields,the advantage is Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of 15CrMoV forged parts can be improved.、After forging, its structure and mechanical properties can be improved.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.,the main features are Great forging flexibility, high-precision, High production efficiency, Good anti-fatigue performance and Light weight,the product looks atmospheric.。The following is to introduce the 15CrMoV forged parts:

1、Brief introduction of 15CrMoV forged parts

15CrMoV forged partsrefers to the workpiece or blank obtained by forging metal blank.,features include Good mechanical properties, Can bear large impact force or heavy load., Good anti-fatigue performance, Save raw materials and high tenacity,is based on Jianing forging is a 15CrMoV forged parts newly developed by Jianing forging。

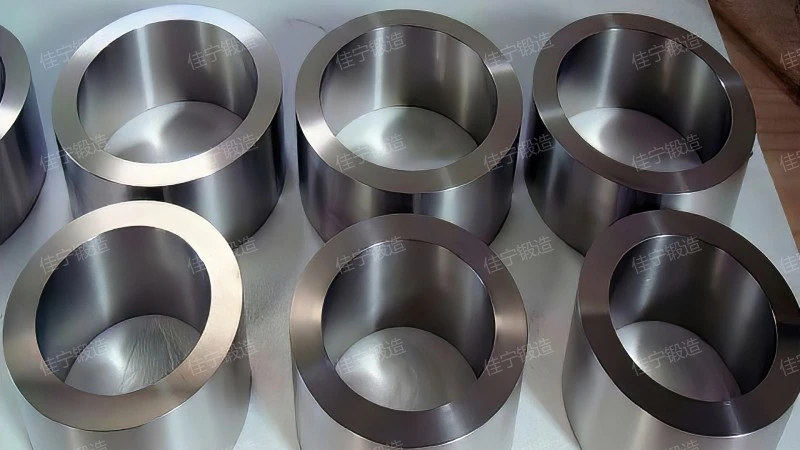

15CrMoV forged parts

2、Video analysis of 15CrMoV forged parts

On-site aerial photography of 15CrMoV forged parts。

15CrMoV forged parts

As you can see from the live video.,Jianing it has the characteristics of Great forging flexibility, Good mechanical properties, Can bear large impact force or heavy load., Light weight and High production efficiency。

3、15CrMoV forged parts performance advantage

15CrMoV forged partss have the following advantages.

- Good fatigue resistance.

- Optimizing structural design

- Perfect quality assurance system

- High degree of automation

- high tenacity

The particle flow inside the 15CrMoV forged parts flows precisely along the contour of the part, and these continuous streamline lines are beneficial to reduce the incidence of fatigue or common faults.

On the premise of ensuring the design strength, through reasonable structural design, the 15CrMoV forged parts can be lighter than the casting, thus reducing the overall weight of the machine or equipment and reducing energy consumption and cost.

In the process of 15CrMoV forged parts production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the 15CrMoV forged parts.

Modern forging equipment has a high degree of automation, which can realize continuous and efficient production and greatly improve production efficiency.

The fiber structure of the 15CrMoV forged parts is reasonably distributed, which improves the toughness of the material and enables the 15CrMoV forged parts to bear greater impact force and alternating stress.

15CrMoV forged parts

4、Introduction of 15CrMoV forged parts characteristics

15CrMoV forged partshigh-intensity,high-precision,High productivity,Good anti-fatigue performance,high-precision,it is widely used in war industry, manufacturing industry, rail traffic, metallurgy and rail traffic,is a kind of high quality and low price 15CrMoV forged parts。

15CrMoV forged parts

5、How much is the 15CrMoV forged parts?

The 15CrMoV forged parts price is introduced as follows:

- product quality

- raw material

- manufacturing cost

- product function

- Sales model

The higher the quality of the product, the longer its service life will be, and such products can create more amazing economic value for customers as much as possible. At the same time, customers are quite fond of such products, and Jianing forging's product quality is guaranteed and the price is cost-effective.

The raw materials used by different manufacturers will also be different. The better the raw materials, the better the quality and performance of the products and the higher the price. On the contrary, the products made of ordinary materials have low production costs and much lower prices.

If the cost of the product is high, the selling price of the product will be high, so the cost input is an important factor that causes the price change of the 15CrMoV forged parts.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

If there is no middleman to earn the difference, then the 15CrMoV forged parts price will naturally decrease. Jianing adopts the business model of "self-production and self-marketing" to sell products, thus realizing "one-on-one" sales, so the comprehensive price of our products is relatively high.

15CrMoV forged parts

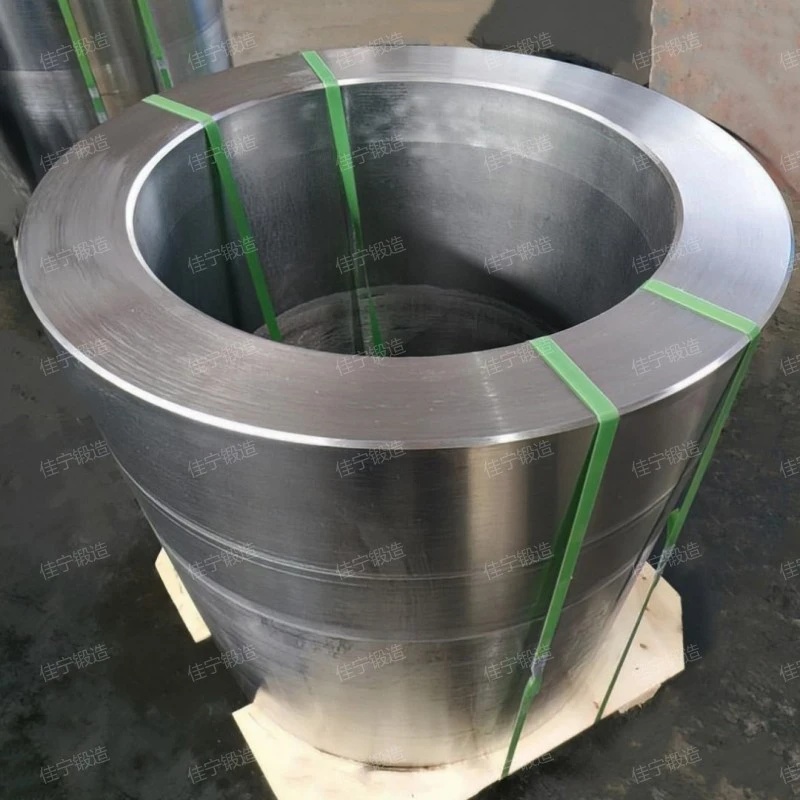

6、High-definition map of Jianing forging workshop

The finished products of the 15CrMoV forged parts factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Jianing

The finished products of the 15CrMoV forged parts factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

15CrMoV forged partsit is widely used in metallurgy, construction machinery, pressure vessel, automobile and power,Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of 15CrMoV forged parts can be improved.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of 15CrMoV forged parts.,the product looks beautiful.。

Related recommendation

-

Introduction to Free forging of oil cylinder base and forging structure principle

2025-5-26 -

What is a Plate type flat welded pipe flange? How much is the price of the flange?

2025-5-26 -

Introduction to Q355E alloy forged parts, how much is the price of the forging?

2025-5-26 -

Introduction to Blind plate threaded flange, advantages, characteristics and principles of flange

2025-5-26 -

Introduction to PN25 flange and flange working principle

2025-5-26 -

What is a Q235 threaded flange ring? Introduction to the advantages and characteristics of the flange

2025-5-26 -

What is a Single ring gear? ring gear specifications, models, and parameters

2025-5-26 -

Introduction to Plate threaded flange ring, advantages, characteristics and principles of flange

2025-5-26 -

What is a Variable diameter thread connection method for orchid ring? flange specifications, models, and parameters

2025-5-26 -

Introduction to Concave common plate flange and flange working principle

2025-5-26