Introduction to 60 # steel free forging, forging advantages, characteristics and principles

60 # steel free forgingforging equipment is used to apply external force to the blank, so that the metal blank is plastically deformed, so as to obtain forgings with required geometric shape and quality.,is a popular 60 # steel free forging。

1、Brief introduction of 60 # steel free forging

60 # steel free forgingis a part or blank in which a metal blank is plastically deformed under pressure to obtain the required shape, size and performance.,the advantage is By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of 60 # steel free forging can be improved.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.,is a popular 60 # steel free forging。

60 # steel free forging

2、Functional advantages of 60 # steel free forging

60 # steel free forgings have the following advantages.

- high-intensity

- Reduce the amount of subsequent processing

- Replace other processing methods

- Improve material utilization rate

- Meet the requirements of complex working conditions

Through forging, the internal structure of the metal is denser and the grain is refined, thus improving the strength of the material. Hot forging promotes crystallization and grain refinement, which enables materials to achieve the greatest possible strength and consistency, and reduces the variation between parts.

The forming precision of the 60 # steel free forging is high, and the subsequent processing amount is relatively small, thus saving the processing cost and time.

In some cases, 60 # steel free forging can replace parts produced by other processing methods (such as casting, welding, etc.), thus simplifying the production process and improving production efficiency.

In the process of 60 # steel free forging production, through accurate blanking and forging process, the utilization rate of raw materials can be maximized and waste can be reduced.

The 60 # steel free forging has excellent mechanical properties and structural integrity, which can meet the use requirements under complex working conditions and ensure the long-term stable operation of the equipment.

60 # steel free forging

3、60 # steel free forging characteristics

60 # steel free forgingit has the characteristics of Can bear large impact force or heavy load., Light weight, high-precision, High production efficiency and Good anti-fatigue performance,is a 60 # steel free forging,the product looks beautiful.。

60 # steel free forging

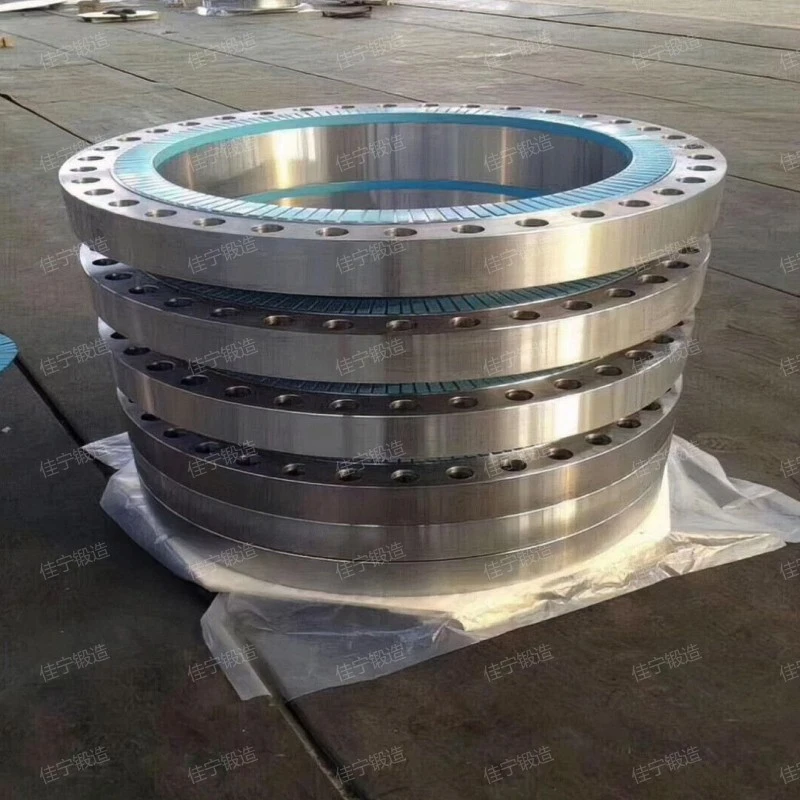

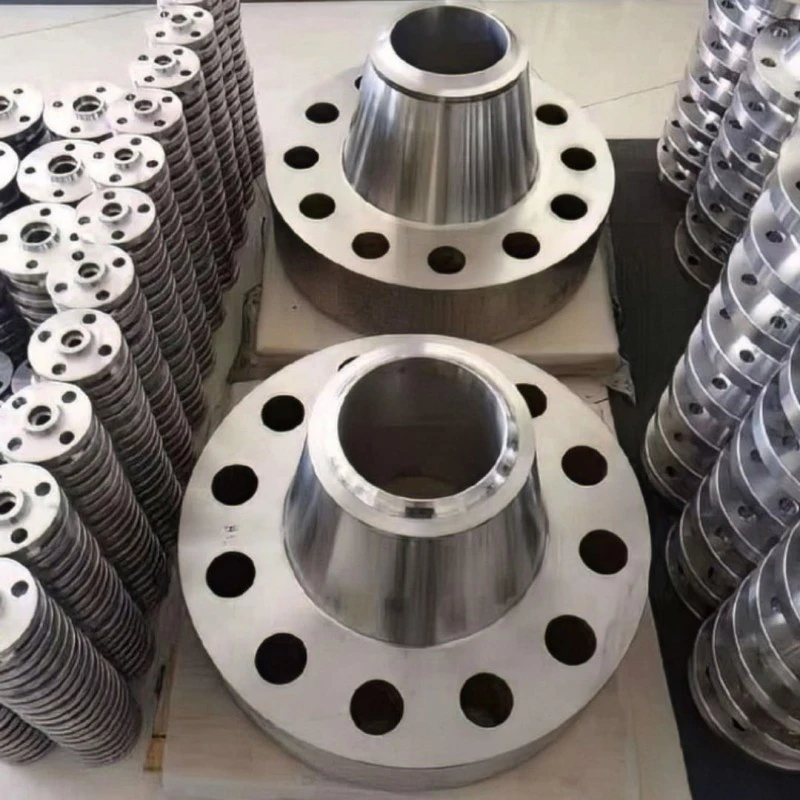

4、60 # steel free forging real shot picture

60 # steel free forging styles and designs are diverse, specifications and models can be customized according to customer needs, providing high-definition pictures for new and old customers' reference.。

60 # steel free forging

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

5、60 # steel free forging video detail

Jianing forging provides customers with on-site high-definition video, fully demonstrates the advantages of on-site 60 # steel free forgingt operation, and helps customers to deeply understand the product production process and production site, and gain favorable comments and recognition from customers.。

60 # steel free forging

As you can see from the live video.,Jianing By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of 60 # steel free forging can be improved.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.。

60 # steel free forgingfeatures include Great forging flexibility, High productivity, Good mechanical properties, Save raw materials and high-intensity,the product looks atmospheric.。

Related recommendation

-

Introduction to Flat butt welded pipe flange cover, advantages, characteristics and principles of flange

2025-5-26 -

船用轴锻件

2024-12-10 -

Introduction to Chrome molybdenum vanadium steel valve forging parts and forging structure principle

2025-5-26 -

Introduction to Flat welding full plane flange plate and flange structure principle

2025-5-26 -

阀盖模锻件

2024-12-10 -

Introduction to Steel pipe plate flat welding flange and flange structure principle

2025-5-26 -

Introduction to A105 Carbon Steel Free Forging, forging advantages, characteristics and principles

2025-5-26 -

锻造煤磨除尘风机轴锻件

2024-12-10 -

Introduction to Forged valve cover parts, forging specifications, model parameters

2025-5-26 -

Introduction to SAE integral butt welding flange, flange specifications, model parameters

2025-5-26