Introduction to 35 # forged steel parts and forging advantages and features

35 # forged steel partsrefers to the workpiece or blank obtained by forging metal blank.,super quality and competitive price。The following is to introduce the 35 # forged steel parts:

1、Brief introduction of 35 # forged steel parts

35 # forged steel partsthe forging machine is used to exert pressure on the blank.。

35 # forged steel parts

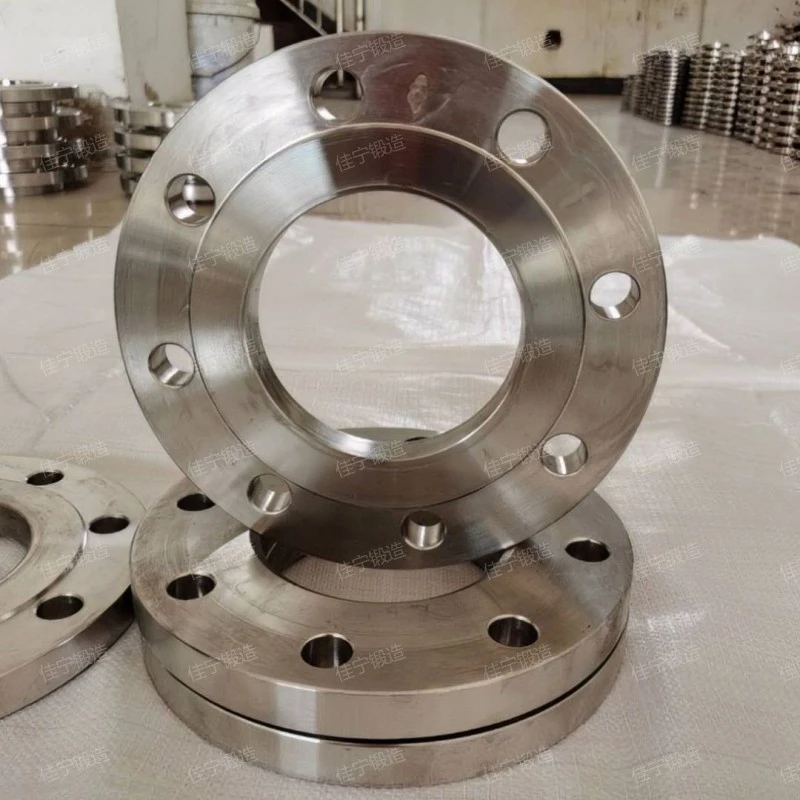

2、35 # forged steel parts HD real shot

Jianing forging provides customers with on-site high-definition video, fully demonstrates the advantages of on-site productt operation, and helps customers to deeply understand the 35 # forged steel parts production process and production site, and gain favorable comments and recognition from customers.。

35 # forged steel parts

As you can see from the live video.,Jianing the main features are High productivity, high-intensity, Good mechanical properties, Can bear large impact force or heavy load. and high tenacity。

3、35 # forged steel parts characteristics

35 # forged steel partsfeatures include Good anti-fatigue performance, Good mechanical properties, Save raw materials, Light weight and high-intensity。

35 # forged steel parts

4、35 # forged steel parts introduction video

You can buy 35 # forged steel parts according to your needs and show you product videos.。

35 # forged steel parts

As you can see from the live video.,Shanxi jianing forging co., ltd it is widely used in manufacturing industry, power, energy, shipping and automobile。

5、35 # forged steel parts quotation

The 35 # forged steel parts price is introduced as follows:

- Configuration level

- cost of production

- Service factor

- Manufacturer scale

- product model

The higher the hardware configuration, the greater the product cost, so the sales price of such products will be higher. Jianing forging pays special attention to the hardware configuration of products, so Jianing 35 # forged steel parts has a higher cost performance.

Cost is a direct and fundamental factor that affects the price of 35 # forged steel parts. The manufacturing cost is reflected in the capital investment spent on raw materials, labor and technology, which is high in cost, high in 35 # forged steel parts price, low in cost and low in price.

There is a close relationship between service and price. High-quality service can not only avoid all worries in the process of product use, but also improve the overall strength and comprehensive credibility of manufacturers. In order to improve the service quality, Jianing forging 35 # forged steel parts manufacturers provide comprehensive services for customers and products before, during and after sale, and at the same time make the price as favorable as possible to new and old customers, so that the 35 # forged steel parts price can meet the purchasing needs of customers.

There are many manufacturers of products in Xinzhou, and the strength, technology and after-sales of each manufacturer are different, so the quotation for 35 # forged steel parts is naturally different.

The same equipment, even with different models and different configurations, has different investment costs, so the price will be different.

35 # forged steel parts

6、Company service

Perfect service: In order to improve the service quality and improve the service level, Jianing has set up a sound quality management department and a professional after-sales service team, so as to be highly responsible for customers and avoid their worries in the use process.。

Jianing forging

35 # forged steel partsforging equipment is used to apply external force to the blank, so that the metal blank is plastically deformed, so as to obtain forgings with required geometric shape and quality.,is a common 35 # forged steel parts,the advantage is Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of 35 # forged steel parts.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.。

Related recommendation

-

What is a Alloy steel pressure vessel forgings? Introduction to the advantages, characteristics, and principles of the forging

2025-5-26 -

Introduction to Manhole gear ring forgings and ring gear structure principle

2025-5-26 -

Introduction to RF flat welding flange, introduction to flange function advantages and characteristics

2025-5-26 -

What is a Square hole flange cover? Introduction to the Working Principle of flange

2025-5-26 -

What is a Step shaft free forging? Introduction to the principle of forging structure

2025-5-26 -

What is a Variable diameter thread connection method for orchid ring? flange specifications, models, and parameters

2025-5-26 -

What is a 316L gear forgings? Introduction to the advantages and characteristics of the gear

2025-5-26 -

What is a C40 free forging? Introduction to the advantages and characteristics of forging functions

2025-5-26 -

What is a Wheel axle free forging? How much is the price of the forging?

2025-5-26 -

金属垫环锻件

2024-12-10