What is a 20 # forged steel parts? Introduction to the advantages and characteristics of forging functions

20 # forged steel partsforging equipment is used to apply external force to the blank, so that the metal blank is plastically deformed, so as to obtain forgings with required geometric shape and quality.,it is widely used in manufacturing industry, automobile, power, metallurgy and energy,features include high tenacity, High production efficiency, Great forging flexibility, high-precision and Good anti-fatigue performance,it can be used in manufacturing industry, war industry, pressure vessel, shipping, automobile and other industries,the product looks atmospheric.。

1、Brief introduction of 20 # forged steel parts

20 # forged steel partsis the metal that exerts pressure to shape the required shape or appropriate compression through plastic deformation.,the advantage is Forging can eliminate metal porosity and holes, and improve the mechanical properties of 20 # forged steel parts.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of 20 # forged steel parts can be improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.,is a common 20 # forged steel parts。

20 # forged steel parts

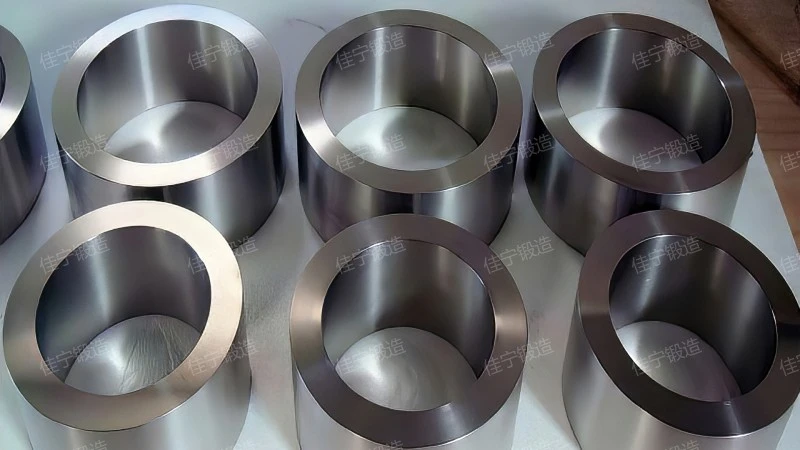

2、20 # forged steel parts real beat

The 20 # forged steel parts has been upgraded, and the beauty of details is appreciated.。

20 # forged steel parts

Note: All the pictures in this article were taken by Jianing manufacturer.。

3、Introduction of advantages of 20 # forged steel parts

20 # forged steel partss have the following advantages.

- High dimensional accuracy

- Optimizing structural design

- Improve material utilization rate

- Eliminate internal defects

- Good chemical uniformity

In the forging process of 20 # forged steel parts, high dimensional accuracy and shape accuracy can be obtained through the precise forming of dies.

On the premise of ensuring the design strength, through reasonable structural design, the 20 # forged steel parts can be lighter than the casting, thus reducing the overall weight of the machine or equipment and reducing energy consumption and cost.

In the process of 20 # forged steel parts production, through accurate blanking and forging process, the utilization rate of raw materials can be maximized and waste can be reduced.

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the 20 # forged steel parts.

Forging can disperse the segregation of alloy or nonmetal and make the 20 # forged steel parts have excellent chemical uniformity.

20 # forged steel parts

4、Introduction of 20 # forged steel parts characteristics

20 # forged steel partsHigh productivity,Good mechanical properties,Save raw materials,Can bear large impact force or heavy load.,Light weight,the advantage is Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of 20 # forged steel parts can be improved.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of 20 # forged steel parts.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.,the product looks atmospheric.,favorable price。

20 # forged steel parts

5、How much is the 20 # forged steel parts?

The 20 # forged steel parts price is introduced as follows:

- marketing channel

- manufacturing cost

- select a qualified person

- product function

- deploy

If there is no middleman to earn the difference, then the 20 # forged steel parts price will naturally decrease. Jianing forging adopts the business model of "self-production and self-marketing" to sell products, thus realizing "one-on-one" sales, so the comprehensive price of our products is relatively high.

A 20 # forged steel parts needs to spend a lot of manufacturing costs from research and development to production to sales, including raw material costs, technical costs, labor costs, etc. The higher the manufacturing cost, the higher the price will be.

The higher the cost of materials, the higher the price will be. In the process of purchasing, customers need to make a detailed understanding of the materials selected for manufacturing products.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

If the comprehensive configuration of the product is higher, the selling price of the product will be higher, otherwise the price will be lower, so there is a close relationship between the configuration level and the price.

20 # forged steel parts

6、Jianing service

Jianing forging's after-sales service is in place, and the after-sales service is one-stop, and the installation, training and production are in place at one time, creating higher economic benefits.。

Jianing

20 # forged steel partsAfter forging, its structure and mechanical properties can be improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、After forging, its structure and mechanical properties can be improved.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.,the product looks beautiful.。

Related recommendation

-

Introduction to Q345B alloy free forging, introduction to forging advantages and characteristics

2025-5-26 -

What is a Electric shaft forgings? Introduction to the principle of forging structure

2025-5-26 -

What is a Alloy steel ring forging? Introduction to the advantages and characteristics of the forging

2025-5-26 -

What is a DN700 flange cover? How much is the price of the flange?

2025-5-26 -

What is a Flat flat welding flange plate? How much is the price of the flange?

2025-5-26 -

What is a Flat welding irregular flange? Introduction to the advantages and characteristics of flange functions

2025-5-26 -

Introduction to Free forging of axle head and forging advantages and features

2025-5-26 -

40Cr4NiMo轧辊毛坯锻件

2024-12-10 -

Introduction to Chemical flat welding flange cover, how much is the price of the flange?

2025-5-26 -

Introduction to Bearing gear, introduction to gear function advantages and characteristics

2025-5-26