Introduction to 9Cr18 free forging, forging advantages, characteristics and principles

9Cr18 free forgingis the metal that exerts pressure to shape the required shape or appropriate compression through plastic deformation.,the main features are high-intensity, High production efficiency, High productivity, Save raw materials and high-precision,the product looks beautiful.,it is an ideal choice for customers to buy 9Cr18 free forging。

1、Brief introduction of 9Cr18 free forging

9Cr18 free forgingrefers to the workpiece or blank obtained by forging metal blank.,it is widely used in power, construction machinery, war industry, manufacturing industry, power and other industries,Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、After forging, its structure and mechanical properties can be improved.,Can bear large impact force or heavy load.,Good mechanical properties,Light weight,Good anti-fatigue performance,High productivity,reliable quality,favorable price。

9Cr18 free forging

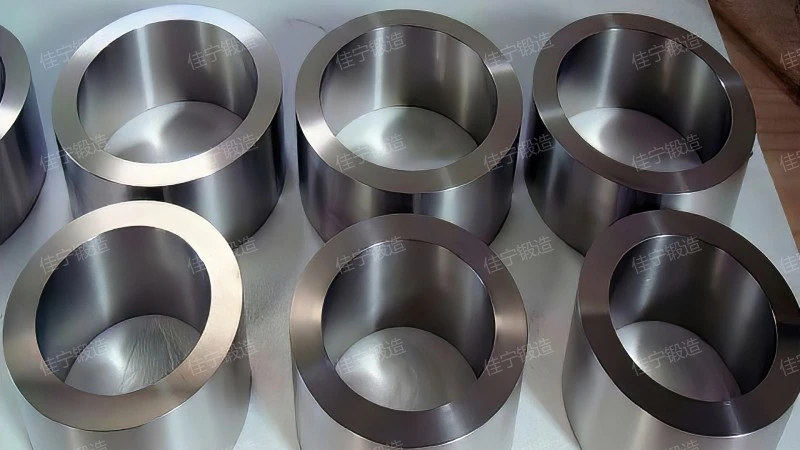

2、9Cr18 free forging real beat

Haide 9Cr18 free forging manufacturing factory。

9Cr18 free forging

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

3、Introduction of 9Cr18 free forging characteristics

9Cr18 free forgingit has the characteristics of Great forging flexibility, High production efficiency, high-intensity, high tenacity and Save raw materials,it is widely used in construction machinery, energy, power, metallurgy and manufacturing industry。

9Cr18 free forging

4、Introduction of advantages of 9Cr18 free forging

The advantages of 9Cr18 free forging are as follows:

- High dimensional accuracy

- Meet the requirements of complex working conditions

- high-intensity

- High degree of automation

- Eliminate internal defects

In the forging process of 9Cr18 free forging, high dimensional accuracy and shape accuracy can be obtained through the precise forming of dies.

The 9Cr18 free forging has excellent mechanical properties and structural integrity, which can meet the use requirements under complex working conditions and ensure the long-term stable operation of the equipment.

Through forging, the internal structure of the metal is denser and the grain is refined, thus improving the strength of the material. Hot forging promotes crystallization and grain refinement, which enables materials to achieve the greatest possible strength and consistency, and reduces the variation between parts.

Modern forging equipment has a high degree of automation, which can realize continuous and efficient production and greatly improve production efficiency.

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the 9Cr18 free forging.

9Cr18 free forging

5、9Cr18 free forging quotation

The 9Cr18 free forging price is introduced as follows:

- product quality

- Model specification

- Product technology

- service

- product function

Quality is the fundamental factor that determines the price. The better the quality, the more detailed the manufacturing process, the more careful the materials are, the better the performance is, and the price will naturally be more expensive.

The same equipment, even with different models and different configurations, has different investment costs, so the price will be different.

The more advanced the technology, the higher the price will be, otherwise the product price will be low, and customers must pay attention to whether their own technology meets the production requirements when purchasing products.

Service factors always affect the sales price of products, and high-quality service will make customers have greater satisfaction and recognition. The service factors mainly include pre-sales service, in-sales service and after-sales service. For each stage of service, our company takes the price factor into account and makes a reasonable judgment between service and price, so that the 9Cr18 free forging price and service can meet the actual needs of customers.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

9Cr18 free forging

6、High-definition map of Jianing forging workshop

The finished products of the 9Cr18 free forging factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Jianing

The finished products of the 9Cr18 free forging factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

9Cr18 free forgingit is widely used inmetallurgy,shipping,rail traffic,pressure vessel,automobile and other industries,refers to the workpiece or blank obtained by forging metal blank. In the process of forging, the metal blank is plastically deformed under the pressure of forging hammer, press and other equipment, and then its shape, size and organizational structure are changed to meet specific use requirements.。

Related recommendation

-

What is a Lining ring flat flange cover? flange specifications, models, and parameters

2025-5-26 -

Introduction to Flat welded tenon groove flange cover, flange specifications, model parameters

2025-5-26 -

支撑轴锻件

2024-12-10 -

Introduction to RF facing welding flange and flange advantages and features

2025-5-26 -

What is a Plate type reducing flange cover? Introduction to the advantages and characteristics of flange functions

2025-5-26 -

What is a 50SiMn forged parts? Introduction to the principle of forging structure

2025-5-26 -

冷却风机轴毛坯锻件

2024-12-10 -

Introduction to Carbon steel plate flat welded pipe flange ring, introduction to flange function advantages and characteristics

2025-5-26 -

What is a 20 # steel free forging? forging specifications, models, and parameters

2025-5-26 -

Introduction to Pipe gear ring forgings, introduction to ring gear advantages and characteristics

2025-5-26