Introduction to 25Mn forged parts, forging specifications, model parameters

25Mn forged partsplastic deformation is made to obtain forgings with certain shapes and mechanical properties.,Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、After forging, its structure and mechanical properties can be improved.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of 25Mn forged parts.,has been favored by more and more customers.。

1、Brief introduction of 25Mn forged parts

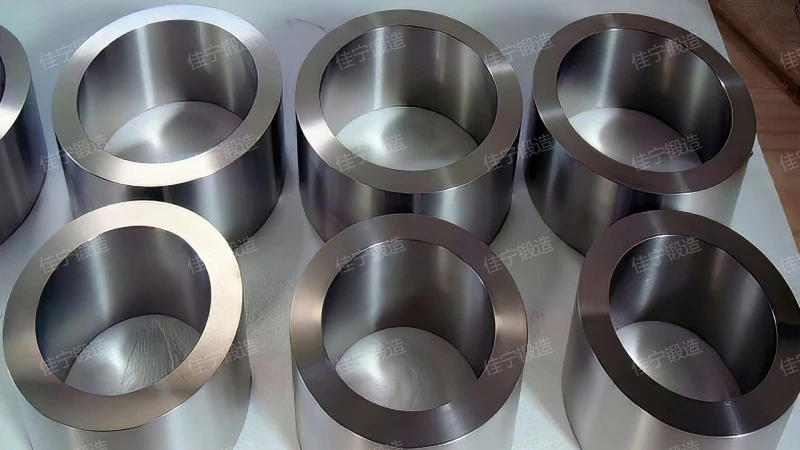

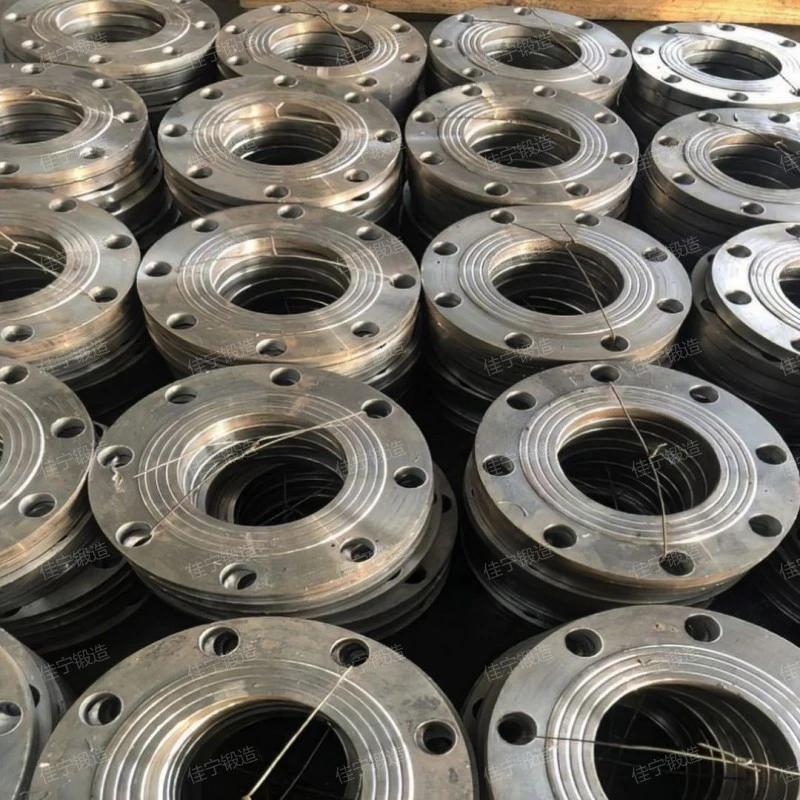

25Mn forged partsthe forging machine is used to exert pressure on the blank.,the product looks beautiful.,is a kind of high quality and low price 25Mn forged parts,usually used in manufacturing industry, automobile, energy, pressure vessel, metallurgy and other fields,Cheap and high quality。

25Mn forged parts

2、Introduction of advantages of 25Mn forged parts

25Mn forged partss have the following advantages.

- High degree of automation

- Meet the requirements of complex working conditions

- Perfect quality assurance system

- Good fatigue resistance.

- Reduce the amount of subsequent processing

Modern forging equipment has a high degree of automation, which can realize continuous and efficient production and greatly improve production efficiency.

The 25Mn forged parts has excellent mechanical properties and structural integrity, which can meet the use requirements under complex working conditions and ensure the long-term stable operation of the equipment.

In the process of 25Mn forged parts production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the 25Mn forged parts.

The particle flow inside the 25Mn forged parts flows precisely along the contour of the part, and these continuous streamline lines are beneficial to reduce the incidence of fatigue or common faults.

The forming precision of the 25Mn forged parts is high, and the subsequent processing amount is relatively small, thus saving the processing cost and time.

25Mn forged parts

3、25Mn forged parts introduction video

Speak directly with facts on the spot。

25Mn forged parts

As you can see from the live video.,Jianing the product looks beautiful.。

4、Functional advantages of 25Mn forged parts

The advantages of 25Mn forged parts are as follows:

- high tenacity

- Good chemical uniformity

- Replace other processing methods

- Eliminate internal defects

- Perfect quality assurance system

The fiber structure of the 25Mn forged parts is reasonably distributed, which improves the toughness of the material and enables the 25Mn forged parts to bear greater impact force and alternating stress.

Forging can disperse the segregation of alloy or nonmetal and make the 25Mn forged parts have excellent chemical uniformity.

In some cases, 25Mn forged parts can replace parts produced by other processing methods (such as casting, welding, etc.), thus simplifying the production process and improving production efficiency.

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the 25Mn forged parts.

In the process of 25Mn forged parts production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the 25Mn forged parts.

25Mn forged parts

5、25Mn forged parts quotation

The 25Mn forged parts price is introduced as follows:

- Different regions

- Brand strength

- product costs

- Model size

- mass discrepancy

The consumption level in different regions is different, which directly affects the equipment cost investment. Generally speaking, the higher the consumption level, the higher the cost of production equipment, and the higher the cost investment, the higher the price naturally.

At present, there are various brands of 25Mn forged parts in Xinzhou. The performance, quality and after-sales of products under different brands are different, and the prices of 25Mn forged parts are different.

When it comes to cost, I believe everyone has heard the saying "You get what you want for a price", which shows that the upfront cost of a product is directly proportional to its value. The upfront cost is high, the value is high, the quality is good, and the price is naturally high. The less the cost is, the lower the price is, and the quality is not good.

Specifications and models have a great influence on the price of 25Mn forged parts, so different specifications and models have different selling prices. Customers can reasonably select product specifications and models according to their own needs, so that products can meet their own required standards in terms of specifications and prices.

The quality of products provided by different manufacturers is different, so their prices will be different. Generally, large manufacturers provide products with higher quality, and the cost of technology and materials is more, so the price is relatively high. However, such products have better use effect and can bring longer-term benefits to customers.

25Mn forged parts

6、How to choose the right product manufacturer?

Choosing a suitable 25Mn forged parts manufacturer requires comprehensive consideration of many aspects. First of all, we should examine the strength of manufacturers, including production capacity, R&D team and industry experience. Strong manufacturers can better ensure product supply and innovation ability. Secondly, product quality is the key, and it is evaluated by product certification, material selection and manufacturing process to ensure the durability of products. Product performance can not be ignored, so we should choose manufacturers with matching technical parameters, rich types and customized services according to actual needs. After-sales service is equally important. Professional and timely service team, perfect after-sales content and extensive service network can make users worry about nothing. In addition, market reputation is also an important reference. We can understand the reputation and status of manufacturers through customer evaluation, industry reputation and award-winning honor. Finally, it is necessary to analyze the price and cost performance, and on the premise of ensuring the quality and performance, choose a manufacturer with reasonable price and high cost performance, so as to purchase 25Mn forged parts products that meet the demand and have good cost performance.。

Jianing forging

25Mn forged partsis a popular 25Mn forged parts,the product looks atmospheric.。

Related recommendation

-

What is a Manhole tube plate? Introduction to the advantages, characteristics, and principles of the tube sheet

2025-5-26 -

Introduction to Concave convex sealing face welding flange, introduction to flange advantages and characteristics

2025-5-26 -

Introduction to Variable diameter connection flange ring, introduction to flange function advantages and characteristics

2025-5-26 -

What is a Hydraulic cylinder end cap forging? Introduction to the principle of forging structure

2025-5-26 -

What is a Convex welding flange plate? Introduction to the advantages and characteristics of the flange

2025-5-26 -

Introduction to Activity welding flange cover and flange structure principle

2025-5-26 -

Introduction to Civil defense flange and flange advantages and features

2025-5-26 -

Introduction to Austenitic ring forging parts, forging specifications, model parameters

2025-5-26 -

What is a Flat welded carbon steel flange plate? Introduction to the advantages and characteristics of flange functions

2025-5-26 -

Introduction to Hollow ring forging parts, introduction to forging advantages and characteristics

2025-5-26