Introduction to Four-hole ring gear forgings and ring gear working principle

Four-hole ring gear forgingsis a Four-hole ring gear forgings made by forging process, with specific tooth shape and size to meet the requirements of transmission machinery.。

1、Brief introduction of Four-hole ring gear forgings

Four-hole ring gear forgingsis an important part of transmission mechanical devices.,support customization。

Four-hole ring gear forgings

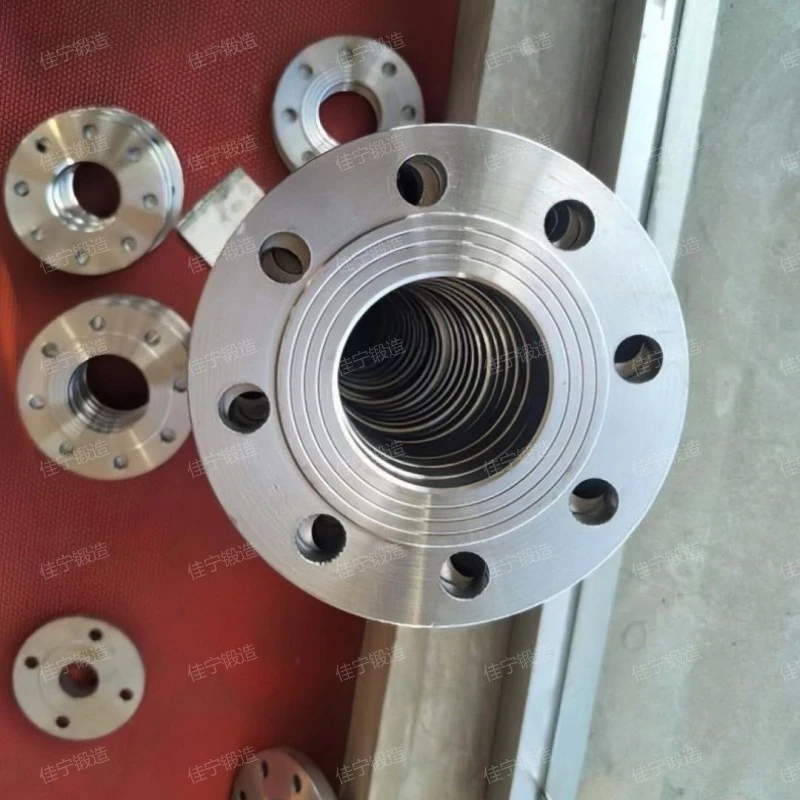

2、Four-hole ring gear forgings HD picture real shot

The following pictures can be used for reference by new and old customers.。

Four-hole ring gear forgings

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

3、Introduction of advantages of Four-hole ring gear forgings

Four-hole ring gear forgingss have the following advantages.

- Good wear resistance

- Improve the overall mechanical properties.

- High precision

- Strong bearing capacity

- Improve production efficiency and material utilization rate

The application of alloy steel material and heat treatment technology makes the Four-hole ring gear forgings surface hard and wear resistant.

Forging process not only improves the strength and toughness of the Four-hole ring gear forgings, but also helps to improve the mechanical properties of the Four-hole ring gear forgings. The improvement of these properties is helpful to improve the overall performance and stability of the transmission system.

Forging process can ensure that the size accuracy and shape accuracy of the Four-hole ring gear forgings reach a high level.

After the forging process, the internal structure of the Four-hole ring gear forgings is compact, and there are no defects such as porosity and slag inclusion, so the bearing capacity is strong.

Forging process can usually form multiple Four-hole ring gear forgingss at one time, and there are fewer subsequent processing steps, thus improving production efficiency. At the same time, due to the high utilization rate of materials in the forging process, the waste of materials is reduced and the production cost is reduced.

Four-hole ring gear forgings

4、Four-hole ring gear forgings application

Four-hole ring gear forgingsIt is a product series that integrates Improve transmission accuracy and efficiency, Transmit motion and power., Improve transmission accuracy and efficiency, Bear load and impact and Transmit motion and power.,it has the characteristics of High shape accuracy, Strong bearing capacity, Good wear resistance, Environmental protection advantage and Thick teeth,is a Four-hole ring gear forgings newly developed by Jianing。

Four-hole ring gear forgings

5、Introduction of Four-hole ring gear forgings characteristics

Four-hole ring gear forgingsit has the characteristics of The rim is toothed., Good wear resistance, Improve the overall mechanical properties., Strong bearing capacity and High shape accuracy,it has been widely used in Construction machinery and equipment, automobile making, mining machinery, petrochemical industry, Construction machinery and equipment and other industries,it is an ideal choice for customers to buy Four-hole ring gear forgings。

Four-hole ring gear forgings

6、Four-hole ring gear forgings price consultation

The Four-hole ring gear forgings price is introduced as follows:

- Company size

- geographical position

- Cost input

- Sales model

- Configuration level

Reliable manufacturers can produce excellent products, and such manufacturers have high comprehensive credibility and can design products in all directions. Therefore, compared with other manufacturers, such products have higher scientific and technological content and more functions. Jianing forging's reputation and products are very high, and it is a trustworthy big brand and manufacturer.

The consumption level in different regions is different, which directly affects the equipment cost investment. Generally speaking, the higher the consumption level, the higher the cost of production equipment, and the higher the cost investment, the higher the price naturally.

The cost of manufacturing Four-hole ring gear forgings varies from manufacturer to manufacturer. The higher the cost of manufacturing products, the higher the product price will be. On the other hand, the lower the production cost, the lower the product price, but the quality of products with high production cost is guaranteed, which can reduce the maintenance cost of customers.

Each manufacturer's sales model is different, and the preferential degree of products is also different. Some manufacturers adopt the mode of "thin profit and quick turnover", and the price is relatively cheap. Some manufacturers sell their products at high prices to earn high profits. When purchasing products, they must compare the prices to avoid being cheated.

Configuration refers to the hardware composition of the product, which mainly includes material selection, parts selection, etc. The higher the overall configuration of the product, the higher the price of the Four-hole ring gear forgings, which is beyond doubt. Jianing makes every product with great care in the attitude of being highly responsible to customers, so the price of Jianing forging Four-hole ring gear forgings is reasonable for products with the same configuration.

Four-hole ring gear forgings

Four-hole ring gear forgingsis a popular Four-hole ring gear forgings,is a mechanical element made by forging process, with teeth on its rim, which can cooperate with other Four-hole ring gear forgingss or racks to realize the transmission of power and movement.。

Related recommendation

-

Introduction to Nut flat welding flange, flange advantages, characteristics and principles

2025-5-26 -

What is a Clamp on flange? How much is the price of the flange?

2025-5-26 -

What is a Concave convex surface threaded flange? flange specifications, models, and parameters

2025-5-26 -

What is a RJ ring connection flange cover? Introduction to the Working Principle of flange

2025-5-26 -

Introduction to Flat plate welded steel flange plate and flange advantages and features

2025-5-26 -

Introduction to Protruding threaded flange and flange working principle

2025-5-26 -

Introduction to Free forging of circular shaft and forging structure principle

2025-5-26 -

Introduction to Docking flat welding flange plate, introduction to flange advantages and characteristics

2025-5-26 -

Introduction to PN65 flange ring, introduction to flange function advantages and characteristics

2025-5-26 -

Introduction to Rotary gear ring forgings, introduction to ring gear advantages and characteristics

2025-5-26