Introduction of Rolling ring forging parts

Rolling ring forging partsis the metal that exerts pressure to shape the required shape or appropriate compression through plastic deformation.,is a kind of high quality and low price Rolling ring forging parts,the advantage is Forging can eliminate metal porosity and holes, and improve the mechanical properties of Rolling ring forging parts.、After forging, its structure and mechanical properties can be improved.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.。

1、Brief introduction of Rolling ring forging parts

Rolling ring forging partsrefers to the workpiece or blank obtained by forging metal blank. In the process of forging, the metal blank is plastically deformed under the pressure of forging hammer, press and other equipment, and then its shape, size and organizational structure are changed to meet specific use requirements.,is a kind of Rolling ring forging parts manufactured by Jianing forging。

Rolling ring forging parts

2、Rolling ring forging parts advantage

The advantages of Rolling ring forging parts are as follows:

- Optimizing structural design

- Replace other processing methods

- Perfect quality assurance system

- high-intensity

- high tenacity

On the premise of ensuring the design strength, through reasonable structural design, the Rolling ring forging parts can be lighter than the casting, thus reducing the overall weight of the machine or equipment and reducing energy consumption and cost.

In some cases, Rolling ring forging parts can replace parts produced by other processing methods (such as casting, welding, etc.), thus simplifying the production process and improving production efficiency.

In the process of Rolling ring forging parts production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the Rolling ring forging parts.

Through forging, the internal structure of the metal is denser and the grain is refined, thus improving the strength of the material. Hot forging promotes crystallization and grain refinement, which enables materials to achieve the greatest possible strength and consistency, and reduces the variation between parts.

The fiber structure of the Rolling ring forging parts is reasonably distributed, which improves the toughness of the material and enables the Rolling ring forging parts to bear greater impact force and alternating stress.

Rolling ring forging parts

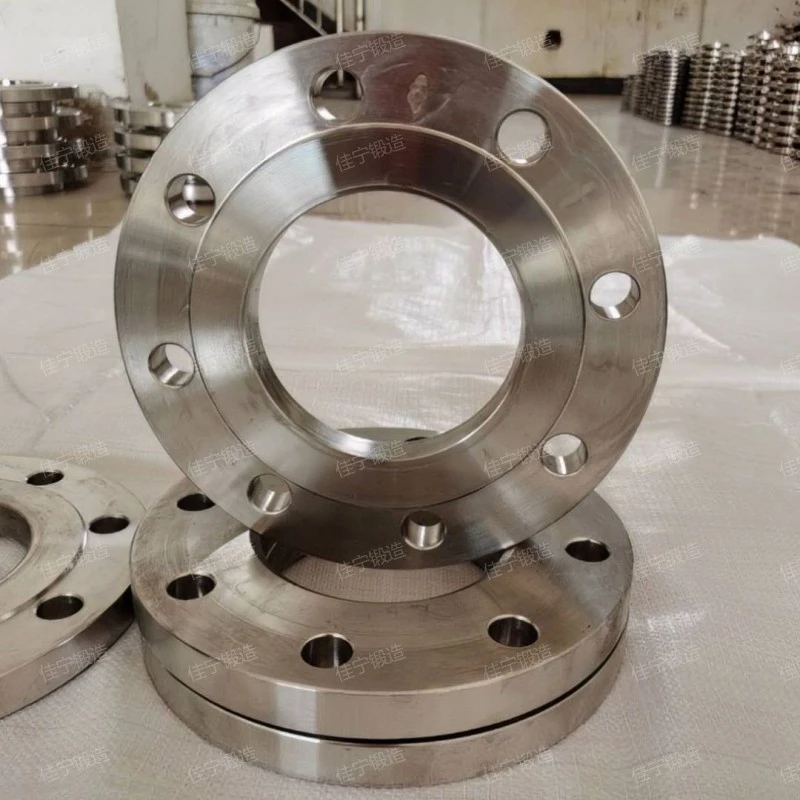

3、Rolling ring forging parts real shot picture

High-definition picture display of Rolling ring forging parts, excellent material selection, reliable quality and trustworthy.。

Rolling ring forging parts

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

4、Introduction of Rolling ring forging parts characteristics

Rolling ring forging partsfeatures include Light weight, high tenacity, high tenacity, Light weight and high-precision,is a popular Rolling ring forging parts,widely used in war industry, shipping, automobile, rail traffic, war industry and other fields,the product looks beautiful.,is based on Jianing is carefully developed by Jianing combined with advanced technology。

Rolling ring forging parts

5、Rolling ring forging parts price consultation

The Rolling ring forging parts price is introduced as follows:

- Cost input

- market factors

- select a qualified person

- Parameter size

- Brand strength

When the Rolling ring forging parts is manufactured, the materials selected by different manufacturers will be different. Some manufacturers use high-quality materials, and the price will be relatively high, while some manufacturers use ordinary materials, and the price will be lower.

Market supply and demand is the inevitable law of market development, with more market supply, less demand and lower product prices; The market supply is small, and people's demand is large. "Things are scarce and expensive", the product price will increase accordingly, and the price of Jianing forging Rolling ring forging parts will also conform to this market law.

The higher the cost of materials, the higher the price will be. In the process of purchasing products, users need to make a detailed understanding of the materials selected for products.

The same product, with different specifications and models, requires different materials and accessories when manufacturing. Moreover, the products with different specifications and models have different performance, and the manufacturers have different production costs, so the prices of products with different specifications and models are also different.

At present, there are various brands of Rolling ring forging parts in Shanxi. The performance, quality and after-sales of products under different brands are different, and the prices of Rolling ring forging parts are different.

Rolling ring forging parts

6、Jianing delivery site

Jianing forging provides customers with on-site high-definition video, fully demonstrates the advantages of on-site productt operation, and helps customers to deeply understand the Rolling ring forging parts production process and production site, and gain favorable comments and recognition from customers.。

Rolling ring forging parts

As you can see from the live video.Jianing is a Rolling ring forging parts。

Rolling ring forging partshigh-intensity,High productivity,Can bear large impact force or heavy load.,High production efficiency,Save raw materials,the product looks atmospheric.。

Related recommendation

-

What is a 1Cr5Mo welded flange cover? Introduction to the principle of flange structure

2025-5-26 -

Introduction to Forged parts of piston rod, how much is the price of the forging?

2025-5-26 -

What is a Irregular thread flange? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

What is a Rolling ring forgings? Introduction to the principle of forging structure

2025-5-26 -

Introduction to Carbon steel threaded flange, introduction to flange advantages and characteristics

2025-5-26 -

What is a DN50 flange plate? Introduction to the Working Principle of flange

2025-5-26 -

Introduction to Mortise and tenon facing welded flange plate, introduction to flange function advantages and characteristics

2025-5-26 -

Introduction to Hydraulic stainless steel flat welding flange cover, advantages, characteristics and principles of flange

2025-5-26 -

What is a 304 stainless steel threaded flange cover? How much is the price of the flange?

2025-5-26 -

Introduction to Q235B carbon steel forged parts and forging advantages and features

2025-5-26