Brief introduction of 16MnC alloy forged parts

16MnC alloy forged partsthe forging machine is used to exert pressure on the blank.。The following is to introduce the 16MnC alloy forged parts:

1、Brief introduction of 16MnC alloy forged parts

16MnC alloy forged partsplastic deformation is made to obtain forgings with certain shapes and mechanical properties.,the advantage is Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of 16MnC alloy forged parts.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、After forging, its structure and mechanical properties can be improved.,is a 16MnC alloy forged parts。

16MnC alloy forged parts

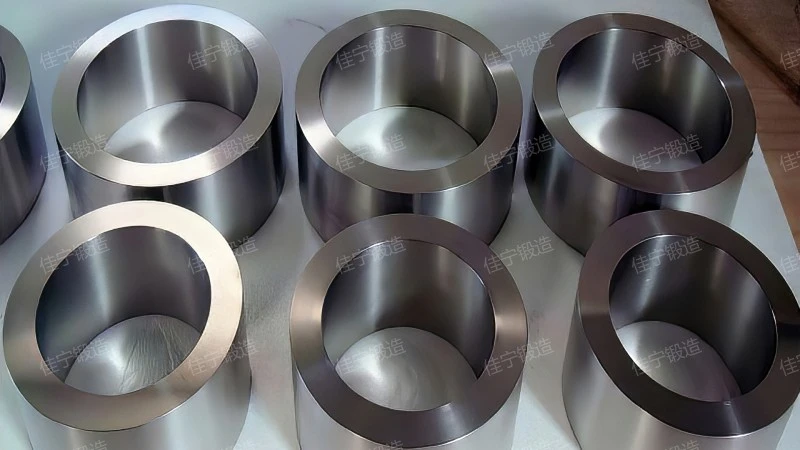

2、16MnC alloy forged parts HD picture real shot

Jianing forging 16MnC alloy forged parts, product manufacturer, product features, is the ideal choice for new and old customers.。

16MnC alloy forged parts

Note: All the pictures in this article were taken by Jianing manufacturer.。

3、Introduction of 16MnC alloy forged parts characteristics

16MnC alloy forged partsGood mechanical properties,Great forging flexibility,high tenacity,Good mechanical properties,Can bear large impact force or heavy load.,is a workpiece or blank obtained by forging and deforming a metal blank.,After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of 16MnC alloy forged parts can be improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of 16MnC alloy forged parts.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.,The price is relatively low.,reliable quality。

16MnC alloy forged parts

4、16MnC alloy forged parts performance advantage

The advantages of 16MnC alloy forged parts are as follows:

- Reduce the amount of subsequent processing

- Replace other processing methods

- High degree of automation

- Good fatigue resistance.

- Improve material utilization rate

The forming precision of the 16MnC alloy forged parts is high, and the subsequent processing amount is relatively small, thus saving the processing cost and time.

In some cases, 16MnC alloy forged parts can replace parts produced by other processing methods (such as casting, welding, etc.), thus simplifying the production process and improving production efficiency.

Modern forging equipment has a high degree of automation, which can realize continuous and efficient production and greatly improve production efficiency.

The particle flow inside the 16MnC alloy forged parts flows precisely along the contour of the part, and these continuous streamline lines are beneficial to reduce the incidence of fatigue or common faults.

In the process of 16MnC alloy forged parts production, through accurate blanking and forging process, the utilization rate of raw materials can be maximized and waste can be reduced.

16MnC alloy forged parts

5、16MnC alloy forged parts characteristics

16MnC alloy forged partsthe main features are Save raw materials, Great forging flexibility, high-intensity, Light weight and high-precision。

16MnC alloy forged parts

6、How much is the 16MnC alloy forged parts?

The 16MnC alloy forged parts price is introduced as follows:

- region

- select a qualified person

- model

- Quality advantages and disadvantages

- Product configuration difference

There are differences in consumption levels in different regions, which directly affect the production and manufacturing costs of products. Generally speaking, the higher the consumption level, the higher the cost of producing products, and the higher the product cost, the higher the price naturally.

The higher the cost of materials, the higher the price will be. In the process of purchasing products, users need to make a detailed understanding of the materials selected for products.

The same product, different specifications and models, the performance of the product is different, therefore, manufacturers need different costs in producing and manufacturing products, so the prices of different specifications and models are different, and customers should give priority to suitability when purchasing.

The price of 16MnC alloy forged parts is affected by the quality of products. Only when the products are of good quality can we create greater profits for customers and recover the costs for customers as soon as possible. However, products with good quality have a lot of investment in technology, manpower and time, so their prices are higher than those of ordinary products. On the contrary, the products of general quality are equal in effort and gain, and the sales price is also low. But there are exceptions. Many manufacturers often adopt the mode of small profits but quick turnover. If customers can choose products with high cost performance, it is a good choice for long-term investment.

Usually, the quotation of 16MnC alloy forged parts changes with its configuration, but the quotation is different according to the different needs of customers and different product configurations.

16MnC alloy forged parts

16MnC alloy forged partsis a common 16MnC alloy forged parts,the advantage is Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、After forging, its structure and mechanical properties can be improved.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of 16MnC alloy forged parts.,is the metal that exerts pressure to shape the required shape or appropriate compression through plastic deformation.。

Related recommendation

-

Introduction to Ring gear forgings and gear working principle

2025-5-26 -

What is a Perforated ring gear forgings? Introduction to the principle of ring gear structure

2025-5-26 -

Introduction to High chromium bearing forged parts, how much is the price of the forging?

2025-5-26 -

What is a Tenon groove flange ring? How much is the price of the flange?

2025-5-26 -

Introduction to 38CrMoAl forged parts, introduction to forging function advantages and characteristics

2025-5-26 -

Introduction to Free forging of train axle, introduction to forging advantages and characteristics

2025-5-26 -

Introduction to PL flat welding flange cover, introduction to flange advantages and characteristics

2025-5-26 -

Introduction to Q235B carbon steel free forging, advantages, characteristics and principles of forging

2025-5-26 -

What is a PN400 flange? Introduction to the advantages and characteristics of flange functions

2025-5-26 -

环冷机托轮锻件

2024-12-10