Introduction of Forging parts of rotary bearing ring

Forging parts of rotary bearing ringis a part or blank in which a metal blank is plastically deformed under pressure to obtain the required shape, size and performance.,be loved by our customers.。The following is to introduce the Forging parts of rotary bearing ring:

1、Brief introduction of Forging parts of rotary bearing ring

Forging parts of rotary bearing ringplastic deformation is made to obtain forgings with certain shapes and mechanical properties.,it is widely used in automobile, pressure vessel, shipping, manufacturing industry and energy。

Forging parts of rotary bearing ring

2、Introduction of Forging parts of rotary bearing ring characteristics

Forging parts of rotary bearing ringGood anti-fatigue performance,high-intensity,Save raw materials,Good mechanical properties,Save raw materials,is a kind of high quality and low price Forging parts of rotary bearing ring,customizable。

Forging parts of rotary bearing ring

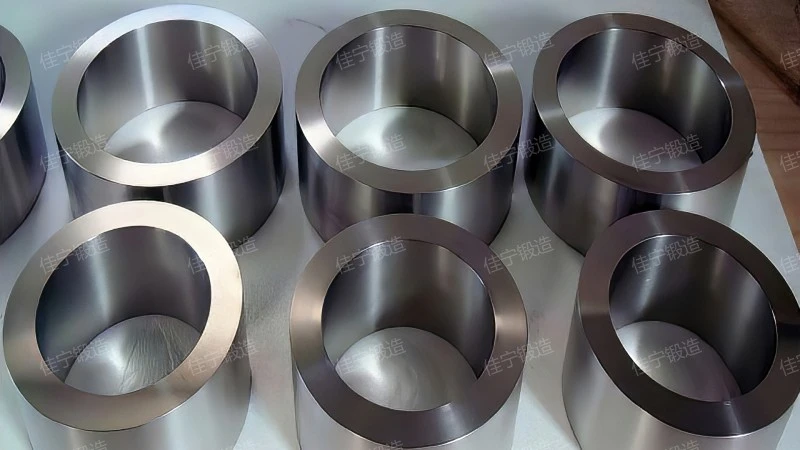

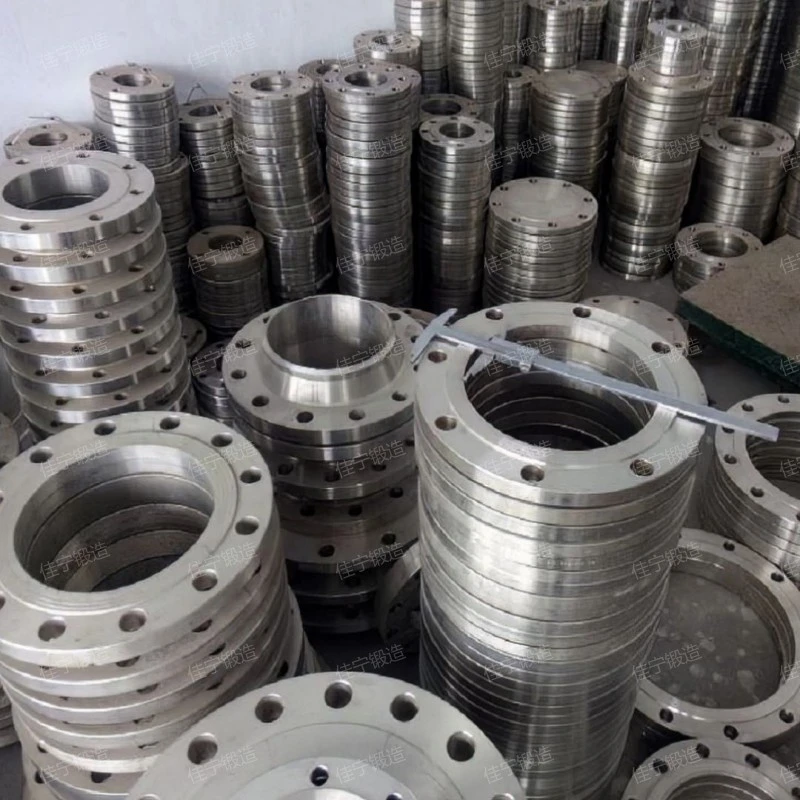

3、Forging parts of rotary bearing ring real shot picture

the product looks atmospheric., advanced technology, complete specifications and models。

Forging parts of rotary bearing ring

Note: All the pictures in this article were taken by Jianing manufacturer.。

4、Forging parts of rotary bearing ring video

Speak directly with facts on the spot。

Forging parts of rotary bearing ring

As you can see from the live video.,Shanxi jianing forging co., ltd it is widely used inpower,war industry,metallurgy,rail traffic,construction machinery and other industries。

5、Functional advantages of Forging parts of rotary bearing ring

Forging parts of rotary bearing rings have the following advantages.

- Meet the requirements of complex working conditions

- high tenacity

- Improve material utilization rate

- Good chemical uniformity

- High degree of automation

The Forging parts of rotary bearing ring has excellent mechanical properties and structural integrity, which can meet the use requirements under complex working conditions and ensure the long-term stable operation of the equipment.

The fiber structure of the Forging parts of rotary bearing ring is reasonably distributed, which improves the toughness of the material and enables the Forging parts of rotary bearing ring to bear greater impact force and alternating stress.

In the process of Forging parts of rotary bearing ring production, through accurate blanking and forging process, the utilization rate of raw materials can be maximized and waste can be reduced.

Forging can disperse the segregation of alloy or nonmetal and make the Forging parts of rotary bearing ring have excellent chemical uniformity.

Modern forging equipment has a high degree of automation, which can realize continuous and efficient production and greatly improve production efficiency.

Forging parts of rotary bearing ring

Forging parts of rotary bearing ringforging equipment is used to apply external force to the blank, so that the metal blank is plastically deformed, so as to obtain forgings with required geometric shape and quality.,is a part or blank in which a metal blank is plastically deformed under pressure to obtain the required shape, size and performance.。

Related recommendation

-

What is a Flat welding full plane flange ring? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

Introduction to Flat welding flange with different necks, how much is the price of the flange?

2025-5-26 -

What is a Flat welding flange ring for orifice plate? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

What is a Q235 flat welding flange plate? Introduction to the advantages and characteristics of flange functions

2025-5-26 -

Introduction to Six hole butt welded flange and flange working principle

2025-5-26 -

What is a Ring neck welded flange cover? Introduction to the Working Principle of flange

2025-5-26 -

Introduction to Flat welding inner wire flange cover, introduction to flange function advantages and characteristics

2025-5-26 -

What is a Flat welded flange with groove? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

Introduction to Q235 convex flange, advantages, characteristics and principles of flange

2025-5-26 -

Introduction to Convex sealing flat welding flange and flange working principle

2025-5-26