Introduction and advantages of Aluminum alloy ring forging parts

Aluminum alloy ring forging partsis a workpiece or blank obtained by forging and deforming a metal blank.,Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Aluminum alloy ring forging parts can be improved.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.,it has the characteristics of Good mechanical properties, Save raw materials, high-intensity, high-intensity and high-precision,the product looks beautiful.,is a kind of high quality and low price Aluminum alloy ring forging parts。

1、Brief introduction of Aluminum alloy ring forging parts

Aluminum alloy ring forging partsrefers to the workpiece or blank obtained by forging metal blank.,it is widely used in metallurgy, shipping, manufacturing industry, power and rail traffic,the product looks beautiful.。

Aluminum alloy ring forging parts

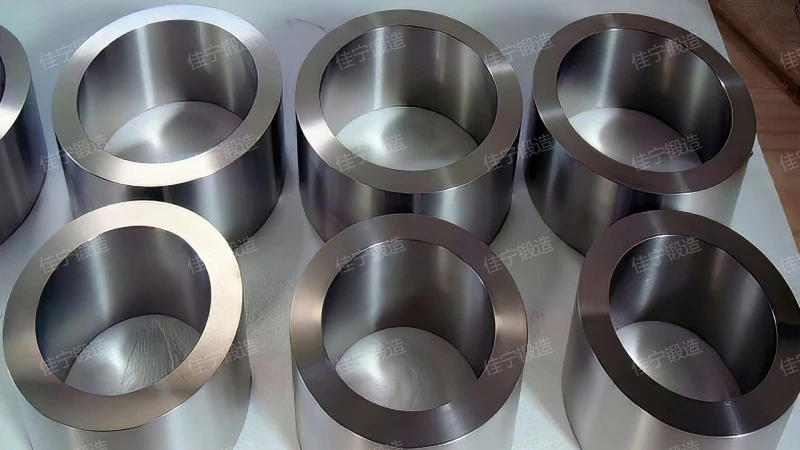

2、Aluminum alloy ring forging parts HD picture real shot

Take a look at the beautiful pictures of the Aluminum alloy ring forging parts, showing the product style.。

Aluminum alloy ring forging parts

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

3、Aluminum alloy ring forging parts display

Overview of high-definition pictures,the product looks atmospheric.。

Aluminum alloy ring forging parts

Note: All the pictures in this article were taken by Jianing manufacturer.。

4、Aluminum alloy ring forging parts performance advantage

The advantages of Aluminum alloy ring forging parts are as follows:

- Perfect quality assurance system

- high tenacity

- Good chemical uniformity

- Reduce the amount of subsequent processing

- Good fatigue resistance.

In the process of Aluminum alloy ring forging parts production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the Aluminum alloy ring forging parts.

The fiber structure of the Aluminum alloy ring forging parts is reasonably distributed, which improves the toughness of the material and enables the Aluminum alloy ring forging parts to bear greater impact force and alternating stress.

Forging can disperse the segregation of alloy or nonmetal and make the Aluminum alloy ring forging parts have excellent chemical uniformity.

The forming precision of the Aluminum alloy ring forging parts is high, and the subsequent processing amount is relatively small, thus saving the processing cost and time.

The particle flow inside the Aluminum alloy ring forging parts flows precisely along the contour of the part, and these continuous streamline lines are beneficial to reduce the incidence of fatigue or common faults.

Aluminum alloy ring forging parts

5、Introduction of Aluminum alloy ring forging parts characteristics

Aluminum alloy ring forging partsSave raw materials,Can bear large impact force or heavy load.,High production efficiency,Great forging flexibility,Light weight,was developed and designed by Jianing forging。

Aluminum alloy ring forging parts

6、Aluminum alloy ring forging parts quotation

The Aluminum alloy ring forging parts price is introduced as follows:

- marketing channel

- market quotation

- Less intermediate links

- raw material

- manufacturing cost

Each manufacturer's sales model is different, and the preferential degree of products is also different. Some manufacturers adopt the mode of "thin profit and quick turnover", and the price is relatively cheap. Some manufacturers sell their products at high prices to earn high profits. When purchasing products, they must compare the prices to avoid being cheated.

Market change is one of the factors that affect the price range greatly. Market change is unstable, but there are certain rules to follow. Market change is caused by other factors, such as economic instability, competition among manufacturers and too big difference between supply and demand. These factors are the core reasons that cause the market to fluctuate greatly, and then it will have a bad impact on prices.

What kind of sales methods manufacturers have has an intuitive impact on product prices. If it is a direct selling manufacturer, the manufacturer sells directly to customers, and there is no intermediate price difference, which can benefit customers to a greater extent.

The raw materials used by different manufacturers will also be different. The better the raw materials, the better the quality and performance of the products and the higher the price. On the contrary, the products made of ordinary materials have low production costs and much lower prices.

Jianing has a large production scale, strong manufacturing strength and high degree of automation in product production. In such a manufacturing environment, the cost of manufacturing Aluminum alloy ring forging parts in Jianing forging is greatly reduced.

Aluminum alloy ring forging parts

Aluminum alloy ring forging partsit is widely used in automobile, energy, shipping, metallurgy and pressure vessel,is a common Aluminum alloy ring forging parts。

Related recommendation

-

What is a Open hole blind flange? Introduction to the principle of blind plate structure

2025-5-26 -

What is a Harvester wheel forgings? Introduction to the principle of wheel structure

2025-5-26 -

What is a 150LB welded flange cover? Introduction to the advantages and characteristics of the flange

2025-5-26 -

Introduction to Q235 carbon steel free forging, how much is the price of the forging?

2025-5-26 -

Introduction to PN100 flange ring, flange specifications, model parameters

2025-5-26 -

What is a Chromium molybdenum vanadium steel valve forgings? Introduction to the principle of forging structure

2025-5-26 -

Introduction to Welding concave flange cover and flange advantages and features

2025-5-26 -

Introduction to Forged parts of oil seal end cap, how much is the price of the forging?

2025-5-26 -

What is a Carbon steel cylinder free forging? Introduction to the advantages, characteristics, and principles of the forging

2025-5-26 -

Introduction to Convex flat plate flat welding flange ring, introduction to flange function advantages and characteristics

2025-5-26