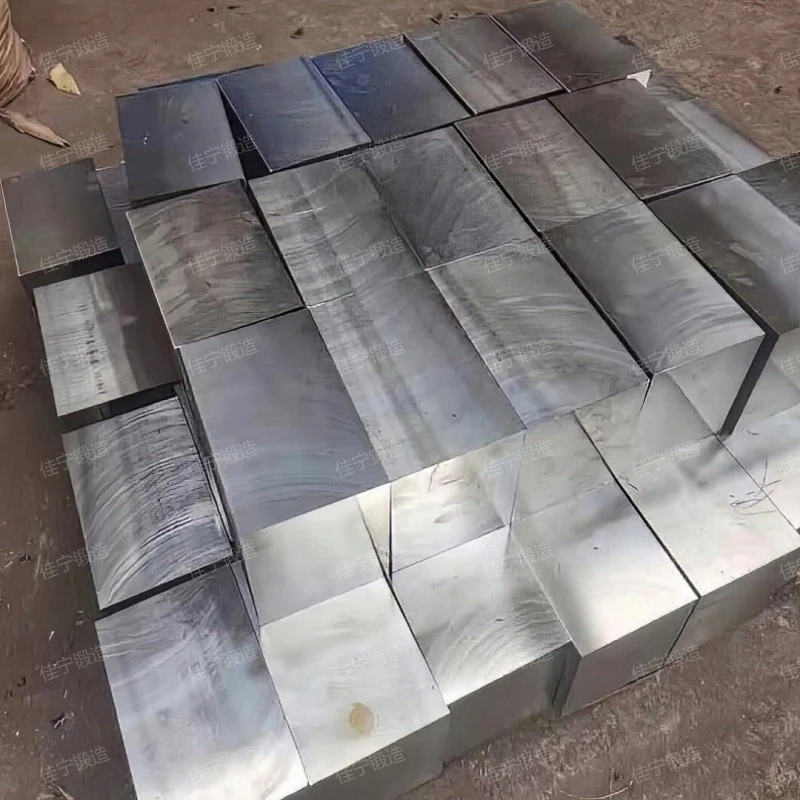

What is a blind plate? blind plate specifications, models, and parameters

blind plateis a common sealing product for pipelines and equipment.。The following is to introduce the blind plate:

1、Brief introduction of blind plate

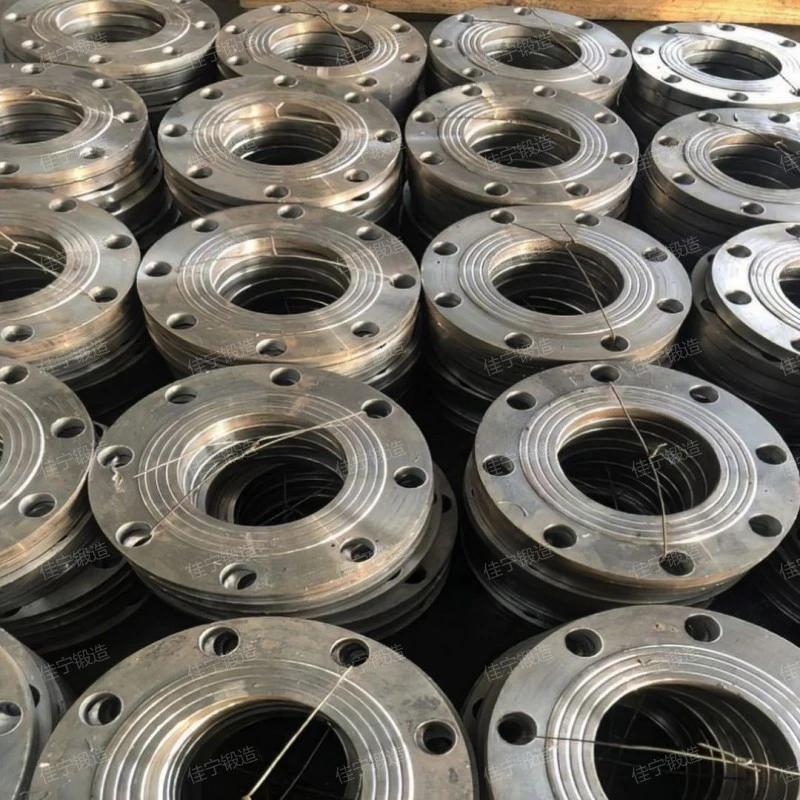

blind plateis a kind of flange with no hole in the middle, which is mainly used to plug the pipeline mouth and isolate and cut off the medium in the pipeline.,The materials are varied, including carbon steel, stainless steel, alloy steel, copper, aluminum, PVC and PPR. These blind plates made of different materials can adapt to different working environments and media requirements, ensuring excellent sealing performance and service life under various working conditions. At the same time, some blind plates made of special materials can also resist the corrosion and erosion of media and prolong the service life of equipment.、Excellent sealing performance can be achieved through its unique sealing surface design and material selection. Whether it is plane seal, concave-convex seal or other forms of seal, the blind plate can ensure that the medium in the pipeline or equipment will not leak, thus ensuring the safety and stability of production. This sealing performance is of great significance for preventing medium pollution and protecting equipment and environment.、It has the characteristics of recycling. This kind of blind plate has low energy consumption and pollution in the process of production and use, which conforms to the concept of green development. With the continuous improvement of environmental awareness, recyclable blind plates will gradually become the mainstream products in the market.、Excellent performance and long life make the overall cost-effectiveness very high. The blind plate can reduce the loss caused by medium leakage and pollution, and reduce the maintenance cost and production cost.、The structure is relatively simple, usually consisting of three parts: main body, sealing element and connecting piece. This structure makes the installation and disassembly of the blind plate very convenient and can quickly adapt to different use scenarios and needs. During pipeline maintenance, replacement or system debugging, the blind plate can quickly achieve isolation and cut-off functions, improving work efficiency.。

blind plate

2、Introduction of blind plate characteristics

blind platethe main features are Recoverable utilization, Good sealing performance, be of simple construction, Environmental protection and energy saving and Economical and practical,It is widely used in the sealing of pipelines and equipment in industries such as make paper. In these industries, blind plates can effectively prevent media leakage and pollution, and ensure the safety and stability of production. At the same time, because of its Various materials, blind plates are also commonly used in pipeline maintenance and replacement, which provides strong support for industrial production.、Excellent performance and long life make the overall cost-effectiveness very high. The blind plate can reduce the loss caused by medium leakage and pollution, and reduce the maintenance cost and production cost.、It has the characteristics of recycling. This kind of blind plate has low energy consumption and pollution in the process of production and use, which conforms to the concept of green development. With the continuous improvement of environmental awareness, recyclable blind plates will gradually become the mainstream products in the market.、The materials are varied, including carbon steel, stainless steel, alloy steel, copper, aluminum, PVC and PPR. These blind plates made of different materials can adapt to different working environments and media requirements, ensuring excellent sealing performance and service life under various working conditions. At the same time, some blind plates made of special materials can also resist the corrosion and erosion of media and prolong the service life of equipment.、Excellent sealing performance can be achieved through its unique sealing surface design and material selection. Whether it is plane seal, concave-convex seal or other forms of seal, the blind plate can ensure that the medium in the pipeline or equipment will not leak, thus ensuring the safety and stability of production. This sealing performance is of great significance for preventing medium pollution and protecting equipment and environment.,the product looks beautiful.,it can be used in Natural gas industry, make paper, chemical lines, pharmacy, Petroleum industry and other industries,has been favored by more and more customers.。

blind plate

3、blind plate application

blind plates have the following purposes.

- Prevent medium leakage

- Isolated piping system

- Protect equipment and pipelines

- Control medium flow direction

- Convenient maintenance and repair

The blind plate has excellent sealing performance, which can effectively prevent the leakage of medium in the pipeline. This is very important to protect the environment and personnel safety, especially when dealing with toxic, harmful or flammable and explosive media.

blind plates are used to isolate a part of the piping system for maintenance, overhaul or replacement of equipment. By installing the blind plate, the medium flow in the pipeline can be cut off and the safety of the working area can be ensured.

In some cases, the pipeline system may be impacted by high pressure, high temperature or corrosive media. The use of blind plates can protect equipment and pipelines from these harsh conditions and prolong their service life.

The blind plate can also be used to control the flow direction of the medium in the pipeline. By installing the blind plate, the flow path of the medium can be changed to meet the process requirements or optimize the production process.

The disassembly of the blind plate makes the maintenance and repair of the pipeline system more convenient and faster, and improves the work efficiency.

blind plate

4、Functional advantages of blind plate

blind plates have the following advantages.

- Recycling, environmental protection and energy saving.

- Economical and practical

- Excellent sealing performance

- Wide range of application

- Simple structure and convenient installation

Some blind plates made of special materials have the characteristics of easy installation. This kind of blind plate has low energy consumption and pollution in the process of production and use, which conforms to the concept of green development. With the continuous improvement of environmental awareness, recyclable blind plates will gradually become the mainstream products in the market.

Although the initial investment of the blind plate may be relatively high, its excellent performance and long life make the overall cost-effectiveness very high. The blind plate can reduce the loss caused by medium leakage and pollution, and reduce the maintenance cost and production cost.

The blind plate can achieve excellent sealing performance through its unique sealing surface design and material selection. Whether it is plane seal, concave-convex seal or other forms of seal, the blind plate can ensure that the medium in the pipeline or equipment will not leak, thus ensuring the safety and stability of production. This sealing performance is of great significance for preventing medium pollution and protecting equipment and environment.

blind plates are widely used in the sealing of pipelines and equipment in industries such as food processing. In these industries, blind plate can effectively prevent media leakage and pollution, and ensure the safety and stability of production. At the same time, because of its simple structure and convenient installation, blind plate are often used in pipeline maintenance and replacement, which provides strong support for industrial production.

The structure of the blind plate is relatively simple, and it usually consists of three parts: the main body, the seal and the connector. This structure makes the installation and disassembly of the blind plate very convenient and can quickly adapt to different use scenarios and needs. During pipeline maintenance, replacement or system debugging, the blind plate can quickly achieve isolation and cut-off functions, improving work efficiency.

blind plate

5、blind plate price advantage

The blind plate price is introduced as follows:

- raw material

- Product configuration difference

- quality factor

- Company size

- Product technology

The higher the cost of materials, the higher the price will be. In the process of purchasing products, users need to make a detailed understanding of the materials selected for products.

The difference in blind plate configuration will affect the product cost price. The higher the configuration, the higher the product cost price and the higher the overall selling price of the product. It is suggested that customers should compare whether the configuration is in line with the quotation when purchasing products, and compare more companies.

Jianing attaches great importance to the quality of products, which can be reflected in the manufacturing process of blind plate and the handling of details. Therefore, there is also a close relationship between quality and price. The price of high-quality products will naturally be high, and vice versa.

Although there are many manufacturers of products in Xinzhou, there are certain differences in the scale and strength of each manufacturer. Some manufacturers are large in scale and strength, some are small in scale, and some manufacturers do not have their own production workshops and belong to middlemen. Relatively speaking, the prices of products formulated by middlemen are higher.

Different manufacturers have different advanced technologies, different production processes and different performances, and the price difference is naturally quite large.

blind plate

6、Jianing forging's strength

The company has many years of blind plate manufacturing experience, large scale and strong strength.。

Jianing

blind plateis a kind of high quality and low price blind plate,the advantage is It is widely used in the sealing of pipelines and equipment in industries such as Natural gas industry. In these industries, blind plates can effectively prevent media leakage and pollution, and ensure the safety and stability of production. At the same time, because of its Strong adaptability, blind plates are also commonly used in pipeline maintenance and replacement, which provides strong support for industrial production.、The materials are varied, including carbon steel, stainless steel, alloy steel, copper, aluminum, PVC and PPR. These blind plates made of different materials can adapt to different working environments and media requirements, ensuring excellent sealing performance and service life under various working conditions. At the same time, some blind plates made of special materials can also resist the corrosion and erosion of media and prolong the service life of equipment.、The structure is relatively simple, usually consisting of three parts: main body, sealing element and connecting piece. This structure makes the installation and disassembly of the blind plate very convenient and can quickly adapt to different use scenarios and needs. During pipeline maintenance, replacement or system debugging, the blind plate can quickly achieve isolation and cut-off functions, improving work efficiency.、It has the characteristics of recycling. This kind of blind plate has low energy consumption and pollution in the process of production and use, which conforms to the concept of green development. With the continuous improvement of environmental awareness, recyclable blind plates will gradually become the mainstream products in the market.、Excellent sealing performance can be achieved through its unique sealing surface design and material selection. Whether it is plane seal, concave-convex seal or other forms of seal, the blind plate can ensure that the medium in the pipeline or equipment will not leak, thus ensuring the safety and stability of production. This sealing performance is of great significance for preventing medium pollution and protecting equipment and environment.。

Related recommendation

-

Introduction to Flat ring gear forgings, advantages, characteristics and principles of ring gear

2025-5-26 -

Introduction to Flat welding protruding flange, introduction to flange advantages and characteristics

2025-5-26 -

What is a DN1300 flange plate? Introduction to the principle of flange structure

2025-5-26 -

What is a Convex panel flat welded stainless steel flange cover? Introduction to the advantages and characteristics of the flange

2025-5-26 -

What is a Dual phase steel forgings? Introduction to the advantages and characteristics of the forging

2025-5-26 -

What is a Manhole tube plate? Introduction to the advantages, characteristics, and principles of the tube sheet

2025-5-26 -

Introduction to Modular free forging and forging structure principle

2025-5-26 -

What is a Side opening flange plate? Introduction to the advantages and characteristics of flange functions

2025-5-26 -

What is a Forging parts for oil cylinder end caps? How much is the price of the forging?

2025-5-26 -

What is a National standard stainless steel forgings? Introduction to the principle of forging structure

2025-5-26