What is a Thick walled tube sheet? tube sheet specifications, models, and parameters

Thick walled tube sheetA hole slightly larger than the outer diameter of the pipe is drilled on the circular steel plate for fixing the pipe and the round steel fittings for sealing the medium. It is usually installed in a heat exchanger, and the pipe is penetrated and welded and fixed, thus playing the role of support and sealing. [Product Name] The machining accuracy, especially the distance between holes, the tolerance of pipe diameter, verticality and smoothness, has an important influence on the assembly and performance of chemical equipment.,is a popular Thick walled tube sheet,is a Thick walled tube sheet newly developed by Jianing forging。

1、Brief introduction of Thick walled tube sheet

Thick walled tube sheetIt is an accessory widely used in various industrial equipment.,be loved by our customers.。

Thick walled tube sheet

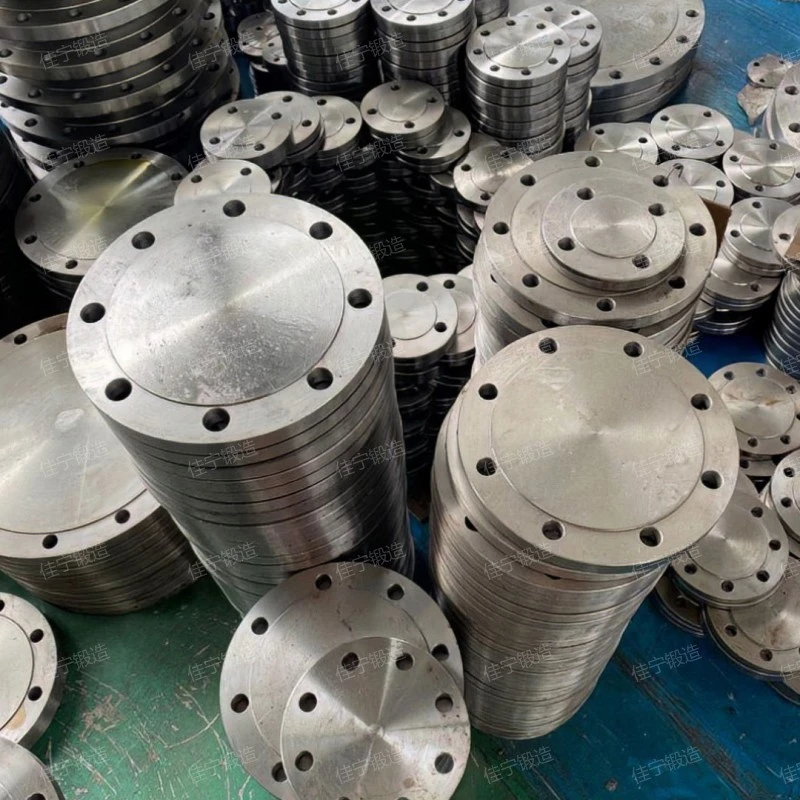

2、Thick walled tube sheet display

Beautiful design, excellent material selection and excellent quality.。

Thick walled tube sheet

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

3、Thick walled tube sheet characteristics

Thick walled tube sheetthe main features are corrosion resistance, Excellent thermal conductivity, High machining accuracy, Good thermal conductivity and corrosion resistance,Commonly used inEasy to maintain and repair.,Support and fixation,Adaptability and corrosion resistance,Improve heat transfer efficiency,Support and fixation and so on,customizable。

Thick walled tube sheet

4、Functional advantages of Thick walled tube sheet

Thick walled tube sheets have the following advantages.

- Support and fixation

- Excellent thermal conductivity

- High heat conduction efficiency

- Improve heat transfer efficiency

- Advanced technology

As a key structural part in the equipment, the Thick walled tube sheet mainly plays the role of supporting and fixing the tubes (or pipes). It ensures that the pipe will not be loosened, displaced or deformed due to fluid impact, vibration or other external forces during the operation of the equipment.

The metal material makes the Thick walled tube sheet have good heat conduction performance, which is helpful for heat transfer in the heat exchanger.

The contact surface between the Thick walled tube sheet and the tube is the main channel for heat transfer. Through the design and optimization of the Thick walled tube sheet, the heat transfer efficiency of the heat exchanger can be improved and the energy consumption can be reduced. This is especially important for industrial processes that require efficient heat exchange.

In heat exchangers and other equipment, the contact surface between the Thick walled tube sheet and the tubes is the main channel for heat transfer. By optimizing the Thick walled tube sheet design and material selection, the efficiency of heat transfer can be improved, energy consumption can be reduced, and the whole equipment can be improved. performance

Modern Thick walled tube sheet production adopts many advanced technologies, such as centrifugal casting, numerical control drilling machine and so on, which improve the quality and performance of the Thick walled tube sheet.

Thick walled tube sheet

5、Thick walled tube sheet application

Thick walled tube sheets have the following purposes.

- Large central air conditioner

- steam turbine

- Condenser, evaporator, seawater desalination equipment

- Large central air conditioner

- pressure vessel

The Thick walled tube sheet plays a role in supporting and fixing the refrigerant pipe in large central air conditioning, which is helpful to the circulation of refrigerant and heat exchange.

In the steam turbine, the Thick walled tube sheet may be used to support and fix some key components to ensure the normal operation of the steam turbine.

In these devices, Thick walled tube sheets are also needed to support the fixed tubes to realize the processes of fluid condensation, evaporation and seawater desalination.

The Thick walled tube sheet plays a role in supporting and fixing the refrigerant pipe in large central air conditioning, which is helpful to the circulation of refrigerant and heat exchange.

In the pressure vessel, the Thick walled tube sheet is used to seal and fix the tubes to prevent medium leakage and ensure the safe operation of the vessel.

Thick walled tube sheet

6、Company preferential activities

Thick walled tube sheet is a new type of tube sheet introduced by Jianing forging manufacturer, which has a wide range of applications, complete structural design and high working efficiency. It is an ideal equipment for boiler and other industries. Now consult Thick walled tube sheet, you can enjoy the discount, and there are many activities for you, such as full reduction and full reduction。

Jianing

Thick walled tube sheetit has the characteristics of High machining accuracy, Strong rigidity, Excellent thermal conductivity, corrosion-resistant and Good thermal conductivity,Widely used inImprove heat transfer efficiency,Support and fixation,Adaptability and corrosion resistance,Sealing and leakage prevention,Improve heat transfer efficiency and so on。

Related recommendation

-

Introduction to Lining ring flat welding flange, introduction to flange advantages and characteristics

2025-5-26 -

Introduction to Flat welded tenon groove flange cover, flange specifications, model parameters

2025-5-26 -

What is a Conical bearing forged parts? Introduction to the advantages and characteristics of the forging

2025-5-26 -

What is a Wind power foundation flange cover? Introduction to the principle of flange structure

2025-5-26 -

What is a 40CrNiMo forging? Introduction to the advantages, characteristics, and principles of the forging

2025-5-26 -

Introduction to Petroleum steel flat welded flange cover, how much is the price of the flange?

2025-5-26 -

起重机车轮锻件

2024-12-10 -

Introduction to 15CrMo flat welding flange ring, flange advantages, characteristics and principles

2025-5-26 -

What is a Cylinder rod head forging? Introduction to the advantages and characteristics of forging functions

2025-5-26 -

What is a Double phase steel flat welding flange cover? Introduction to the advantages and characteristics of the flange

2025-5-26