Introduction to Porous tube plate flange and tube sheet working principle

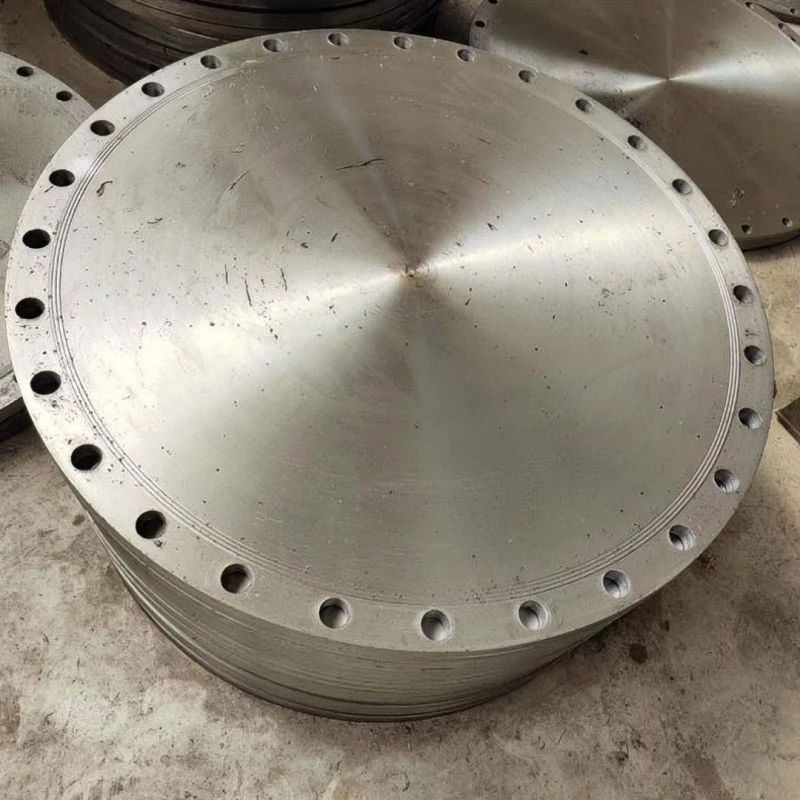

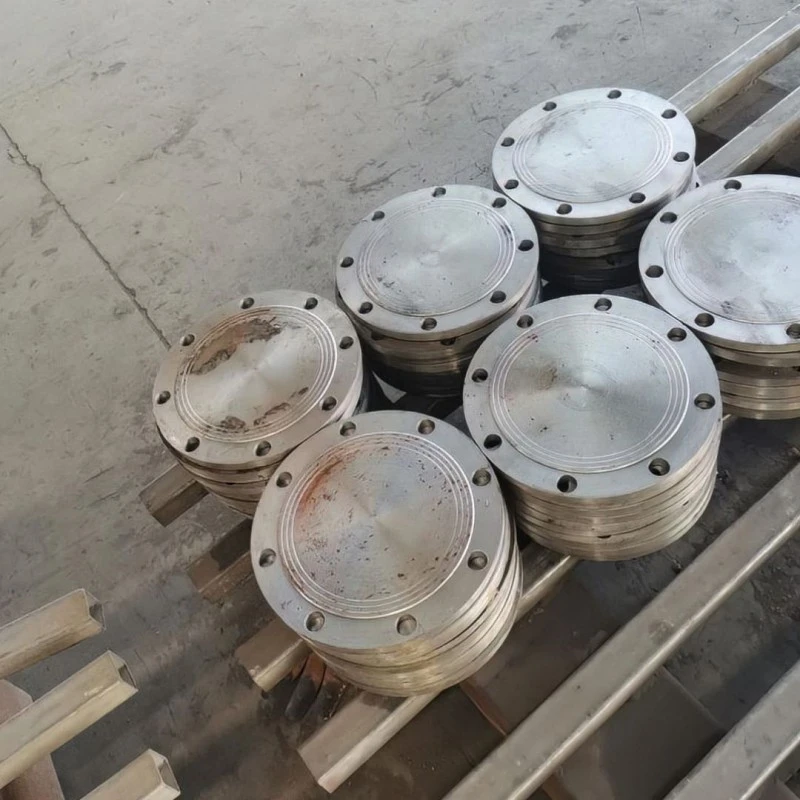

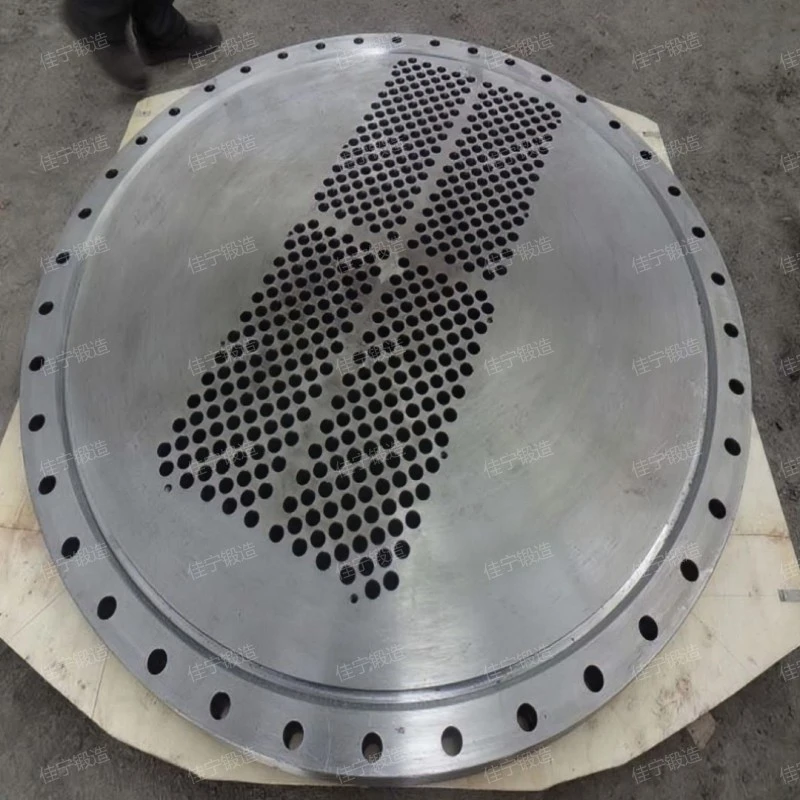

Porous tube plate flangeA hole slightly larger than the outer diameter of the pipe is drilled on the circular steel plate for fixing the pipe and the round steel fittings for sealing the medium. It is usually installed in a heat exchanger, and the pipe is penetrated and welded and fixed, thus playing the role of support and sealing. [Product Name] The machining accuracy, especially the distance between holes, the tolerance of pipe diameter, verticality and smoothness, has an important influence on the assembly and performance of chemical equipment.,the product looks atmospheric.,is a popular Porous tube plate flange,features include High machining accuracy, corrosion-resistant, Good thermal conductivity, Strong rigidity and corrosion resistance,the advantage is Depending on the use environment, the Porous tube plate flange can be made of different materials, such as stainless steel, titanium alloy and other corrosion-resistant materials. This enables the Porous tube plate flange to adapt to various harsh working conditions and prolongs the service life of the equipment.、According to the different use environment, the Porous tube plate flange can be made of corrosion-resistant materials to cope with various harsh working conditions.、The machining accuracy has been significantly improved. High-precision machining ensures the close fit and efficient sealing between the Porous tube plate flange and the tube.、Through accurate processing and assembly, it forms a close fit with the pipe, thus effectively sealing the fluid medium. This sealing function prevents fluid from leaking to the outside of the equipment, ensures the normal operation and safety of the equipment, and also avoids resource waste and environmental pollution.、As a key structural part in the equipment, it mainly plays the role of supporting and fixing the tubes (or pipes). It ensures that the pipe will not be loosened, displaced or deformed due to fluid impact, vibration or other external forces during the operation of the equipment.。

1、Brief introduction of Porous tube plate flange

Porous tube plate flangeIt is an accessory widely used in various industrial equipment.,The production adopts many advanced technologies, such as centrifugal casting and numerical control drilling machine, which improve the quality and performance of the Porous tube plate flange.、As one of the skeletons of heat exchangers and other equipment, it is responsible for supporting and fixing the tubes to ensure that they will not be loose or deformed due to fluid impact during work. This stability is very important for the long-term operation of equipment.、Can be customized according to the actual working conditions and fluid characteristics to meet the needs of different customers. This flexibility makes Porous tube plate flanges widely used in various industrial equipment.、The contact surface with the tubes is the main channel for heat transfer. Through the design and optimization of the Porous tube plate flange, the heat transfer efficiency of the heat exchanger can be improved and the energy consumption can be reduced. This is particularly important for industrial processes that require efficient heat exchange.、Through accurate processing and assembly, the fluid medium can be effectively sealed to prevent it from leaking to the external environment. This not only avoids resource waste and environmental pollution, but also ensures the safe operation of the equipment.,be loved by our customers.。

Porous tube plate flange

2、Porous tube plate flange advantage

Porous tube plate flanges have the following advantages.

- Support and fixation

- Sealing and leakage prevention

- Easy to maintain and repair.

- Support and fixation

- Customizable production

As a key structural part in the equipment, the Porous tube plate flange mainly plays the role of supporting and fixing the tubes (or pipes). It ensures that the pipe will not be loosened, displaced or deformed due to fluid impact, vibration or other external forces during the operation of the equipment.

Through precise machining and assembly, the Porous tube plate flange forms a close fit with the pipe, thus effectively sealing the fluid medium. This sealing function prevents fluid from leaking to the outside of the equipment, ensures the normal operation and safety of the equipment, and also avoids resource waste and environmental pollution.

The structural design of Porous tube plate flanges usually takes into account the convenience of maintenance. For example, some Porous tube plate flanges are connected by flanges, which is convenient for disassembling and replacing pipes, thus reducing the maintenance cost and difficulty.

As a key structural part in the equipment, the Porous tube plate flange mainly plays the role of supporting and fixing the tubes (or pipes). It ensures that the pipe will not be loosened, displaced or deformed due to fluid impact, vibration or other external forces during the operation of the equipment.

Porous tube plate flanges can be customized according to actual working conditions and fluid characteristics to meet the needs of different customers. This flexibility makes Porous tube plate flanges widely used in various industrial equipment.

Porous tube plate flange

3、Porous tube plate flange introduction video

Jianing provides customers with on-site high-definition video, fully demonstrates the advantages of on-site productt operation, and helps customers to deeply understand the product production process and production site, and gain favorable comments and recognition from customers.。

Porous tube plate flange

As you can see from the live video.,Shanxi jianing forging co., ltd It is a kind of fitting with specific holes drilled on circular steel plate, which are slightly larger than the outer diameter of the pipe to be penetrated.。

4、Functional advantages of Porous tube plate flange

Porous tube plate flanges have the following advantages.

- Excellent thermal conductivity

- Advanced technology

- Convenient maintenance

- High precision machining

- Improve heat transfer efficiency

The metal material makes the Porous tube plate flange have good heat conduction performance, which is helpful for heat transfer in the heat exchanger.

Modern Porous tube plate flange production adopts many advanced technologies, such as centrifugal casting, numerical control drilling machine and so on, which improve the quality and performance of the Porous tube plate flange.

The structural design of Porous tube plate flanges usually takes into account the convenience of maintenance. For example, some Porous tube plate flanges are connected by flanges, which is convenient for disassembly and maintenance.

With the application of numerical control technology, the machining accuracy of Porous tube plate flanges has been significantly improved. High-precision machining ensures the close fit and efficient sealing between the Porous tube plate flange and the tube.

In heat exchangers and other equipment, the contact surface between the Porous tube plate flange and the tubes is the main channel for heat transfer. By optimizing the Porous tube plate flange design and material selection, the efficiency of heat transfer can be improved, energy consumption can be reduced, and the whole equipment can be improved. performance

Porous tube plate flange

5、Porous tube plate flange application

Porous tube plate flanges have the following purposes.

- Large central air conditioner

- boiler

- steam turbine

- Condenser, evaporator, seawater desalination equipment

- Condenser, evaporator, seawater desalination equipment

The Porous tube plate flange plays a role in supporting and fixing the refrigerant pipe in large central air conditioning, which is helpful to the circulation of refrigerant and heat exchange.

The Porous tube plate flange also plays an important role in the boiler, which supports the fixed tubes and makes the boiler run stably and efficiently.

In the steam turbine, the Porous tube plate flange may be used to support and fix some key components to ensure the normal operation of the steam turbine.

In these devices, Porous tube plate flanges are also needed to support the fixed tubes to realize the processes of fluid condensation, evaporation and seawater desalination.

In these devices, Porous tube plate flanges are also needed to support the fixed tubes to realize the processes of fluid condensation, evaporation and seawater desalination.

Porous tube plate flange

6、Porous tube plate flange price advantage

The Porous tube plate flange price is introduced as follows:

- company strength

- product configuration

- service

- Cost input

- Less intermediate links

The nature of the manufacturer can also greatly affect the price of the Porous tube plate flange. General manufacturers are divided into direct sellers, agents and middlemen. If they are direct selling manufacturers, there are not too many intermediate links, and their sales prices are low.

There is a direct connection between configuration and specifications. Generally speaking, with different specifications, its configuration scheme will be different, and the selection of products' materials and parts will be different, so the sales price of products will be different. It is not difficult to see that the configuration and price of Porous tube plate flange are closely related. Jianing forging has comprehensively measured the configuration and sales price of products when designing Porous tube plate flange, which not only ensures that the functions of products can meet the actual needs of customers, but also can be in terms of price.

There is a close relationship between service and price. High-quality service can not only avoid all worries in the process of product use, but also improve the overall strength and comprehensive credibility of manufacturers. In order to improve the service quality, Jianing Porous tube plate flange manufacturers provide comprehensive services for customers and products before, during and after sale, and at the same time make the price as favorable as possible to new and old customers, so that the Porous tube plate flange price can meet the purchasing needs of customers.

The production cost determines the price. The production cost here mainly includes technology, materials, technology, manpower and other related factors, among which the technology content is high, and the cost is relatively high, but the performance will be better; The better the quality of raw materials, the greater the cost and the longer the overall life of the product; If the manufacturer has a rational manufacturing process and strict production management system, and can make full use of human and material resources, then it can reduce the waste of expenses and production costs to a great extent, and the Porous tube plate flange just meets this condition, so as to ensure the high-tech content and high quality of products, it can also enjoy low prices.

If there is no middleman to earn the difference, then the Porous tube plate flange price will naturally decrease. Jianing forging adopts the business model of "self-production and self-marketing" to sell products, thus realizing "one-on-one" sales, so the comprehensive price of our products is relatively high.

Porous tube plate flange

Porous tube plate flangethe product looks atmospheric.,it has the characteristics of Excellent thermal conductivity, High strength and rigidity, High machining accuracy, Good thermal conductivity and Strong rigidity。

Related recommendation

-

Introduction to Flat welded thick walled flange and flange working principle

2025-5-26 -

Introduction to 15CrMn forging, advantages, characteristics and principles of forging

2025-5-26 -

Introduction to Pipeline connection flange cover, flange advantages, characteristics and principles

2025-5-26 -

Introduction to Q345B butt welded flange, introduction to flange advantages and characteristics

2025-5-26 -

Introduction to Petrochemical equipment cylinder forging parts, forging advantages, characteristics and principles

2025-5-26 -

What is a DN2200 flange plate? Introduction to the principle of flange structure

2025-5-26 -

Introduction to Q275B Carbon Steel Forged Parts and forging advantages and features

2025-5-26 -

What is a Q345 flat welded flange ring? How much is the price of the flange?

2025-5-26 -

What is a Chassis forging parts? Introduction to the principle of forging structure

2025-5-26 -

Introduction to RF plate flat welding flange ring, advantages, characteristics and principles of flange

2025-5-26