What is a Cylindrical gear forgings? Introduction to the advantages and characteristics of gear functions

Cylindrical gear forgingsis an important part of transmission mechanism, and its rim is designed with teeth, which can continuously mesh to transmit motion and power.,The tooth shape accuracy is high.,High strength,Improve the overall mechanical properties.,High strength and toughness,Can continuously mesh to transmit motion and power.,can be customized according to user's needs.。

1、Brief introduction of Cylindrical gear forgings

Cylindrical gear forgingsis an important part of transmission mechanical devices.,the advantage is Forging process not only improves the strength and toughness of the Cylindrical gear forgings, but also helps to improve the mechanical properties of the Cylindrical gear forgings.、Because of its strong bearing capacity, high precision and good wear resistance, the service life of the Cylindrical gear forgings is relatively long.、It can ensure that the size accuracy and shape accuracy of the Cylindrical gear forgings reach a higher level.、Improve production efficiency and material utilization: Forging process can usually form multiple Cylindrical gear forgingss at one time, and there are fewer subsequent processing steps, thus improving production efficiency. At the same time, due to the high utilization rate of materials in the forging process, the waste of materials is reduced and the production cost is reduced.、In forging process, the dimensional accuracy and shape accuracy of the Cylindrical gear forgings can be ensured through accurate die design and control. Compared with casting and other processes, the forging Cylindrical gear forgings has lower error and more accurate tooth profile, which is helpful to improve the stability and efficiency of the transmission system.,It has a wide range of uses, and is often used inBear load and impact,Bear load and impact,Improve transmission accuracy and efficiency,Transmit motion and power.,Bear load and impact and so on。

Cylindrical gear forgings

2、Introduction of advantages of Cylindrical gear forgings

The advantages of Cylindrical gear forgings are as follows:

- Good wear resistance

- Improve the overall mechanical properties.

- Improve the overall mechanical properties.

- Strong bearing capacity

- Long service life

In the process of forging, the grain of metal material is refined and the hardness is improved, thus enhancing the wear resistance of the Cylindrical gear forgings. This enables the Cylindrical gear forgings to maintain good performance and prolong its service life during long-term use.

Forging process not only improves the strength and toughness of the Cylindrical gear forgings, but also helps to improve the mechanical properties of the Cylindrical gear forgings. The improvement of these properties is helpful to improve the overall performance and stability of the transmission system.

Forging process not only improves the strength and toughness of the Cylindrical gear forgings, but also helps to improve the mechanical properties of the Cylindrical gear forgings. The improvement of these properties is helpful to improve the overall performance and stability of the transmission system.

After the forging process, the internal structure of the Cylindrical gear forgings is compact, and there are no defects such as porosity and slag inclusion, so the bearing capacity is strong.

Because of its strong bearing capacity, high precision and good wear resistance, the service life of the Cylindrical gear forgings is relatively long.

Cylindrical gear forgings

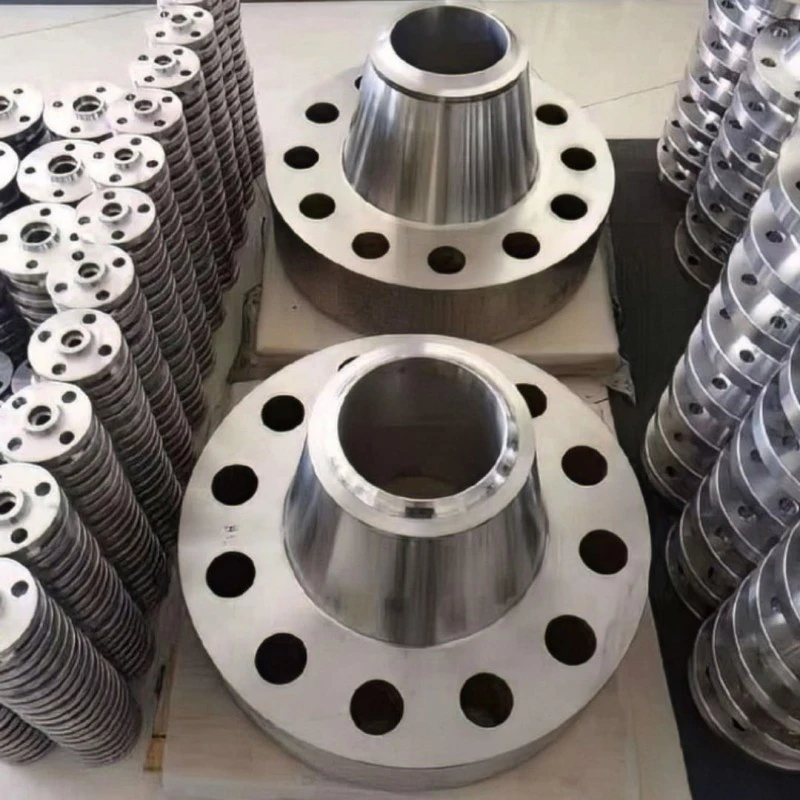

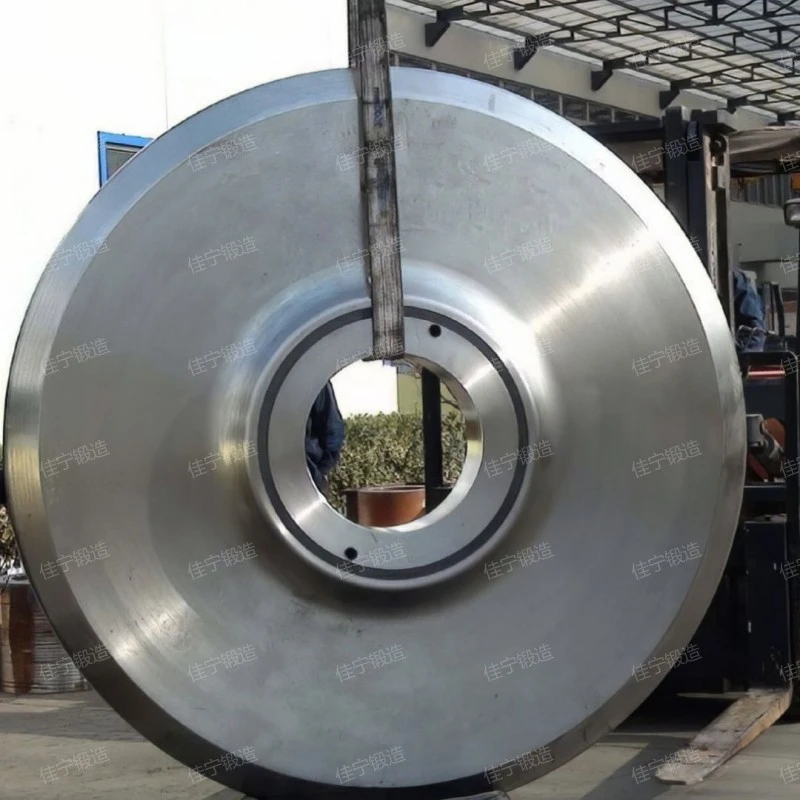

3、Cylindrical gear forgings display

Excellent materials, atmospheric design, fine workmanship, impeccable, trustworthy, all-round high-definition shooting, which is helpful for customers' reference.。

Cylindrical gear forgings

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

4、Cylindrical gear forgings video live broadcast

You can buy Cylindrical gear forgings according to your needs and show you Cylindrical gear forgings videos.。

Cylindrical gear forgings

As you can see from the live video.,Jianing forging is a common Cylindrical gear forgings。

5、Cylindrical gear forgings use

Cylindrical gear forgingsMainly used forImprove transmission accuracy and efficiency,Transmit motion and power.,Bear load and impact,Improve transmission accuracy and efficiency andTransmit motion and power.。

Cylindrical gear forgings

6、How much is the Cylindrical gear forgings?

The Cylindrical gear forgings price is introduced as follows:

- Manufacturer's strength

- product function

- Proper management mode

- Reasonable cost

- Overall configuration

Our company's expected profit value of Cylindrical gear forgings is relatively low, and adopts the sales policy of small profits but quick turnover, so the price positioning of Cylindrical gear forgings is relatively low.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

Jianing Cylindrical gear forgings manufacturer is a large Cylindrical gear forgings manufacturer, the manufacturer produces and sells products directly to customers, without the influence of the price difference between middlemen. The market price of the manufacturer's products is the ex-factory price, and the Cylindrical gear forgings price is also low.

Cost plays a decisive role in the price. The cost mainly includes the initial investment of the product, such as time, manpower and materials selected. The more the investment cost, the higher the relative product pricing. On the contrary, the less the input cost, the lower the price.

If the comprehensive configuration of the product is higher, the selling price of the product will be higher, otherwise the price will be lower, so there is a close relationship between the configuration level and the price.

Cylindrical gear forgings

Cylindrical gear forgingsit is widely used in automobile making, mining machinery, Construction machinery and equipment, mining machinery and petrochemical industry,the product looks beautiful.。

Related recommendation

-

Introduction to Forged parts for hydropower main shaft, forging specifications, model parameters

2025-5-26 -

What is a Step shaft forging parts? Introduction to the Working Principle of forging

2025-5-26 -

Introduction to 304 stainless steel butt welding flange, flange advantages, characteristics and principles

2025-5-26 -

What is a Single blind flange? Introduction to the advantages and characteristics of blind plate functions

2025-5-26 -

Introduction to 40CrMo free forging, introduction to forging function advantages and characteristics

2025-5-26 -

Introduction to Forged parts of cylinder section and forging working principle

2025-5-26 -

Introduction to Toothed gear, how much is the price of the gear?

2025-5-26 -

Introduction to PN160 flange and flange working principle

2025-5-26 -

辊道环锻件

2024-12-10 -

What is a Alloy steel annular free forging? forging specifications, models, and parameters

2025-5-26