Introduction to ring gear, gear specifications, model parameters

ring gearis an important part of transmission mechanical devices.,The price is relatively low.,modern technology。

1、Brief introduction of ring gear

ring gearis a mechanical element made by forging process, with teeth on its rim, which can cooperate with other ring gears or racks to realize the transmission of power and movement.,Widely used inBear load and impact,Improve transmission accuracy and efficiency,Transmit motion and power.,Bear load and impact,Improve transmission accuracy and efficiency and so on,the main features are Environmental protection advantage, The tooth shape accuracy is high., Improve the overall mechanical properties., The tooth shape accuracy is high. and Strong bearing capacity,support customization。

ring gear

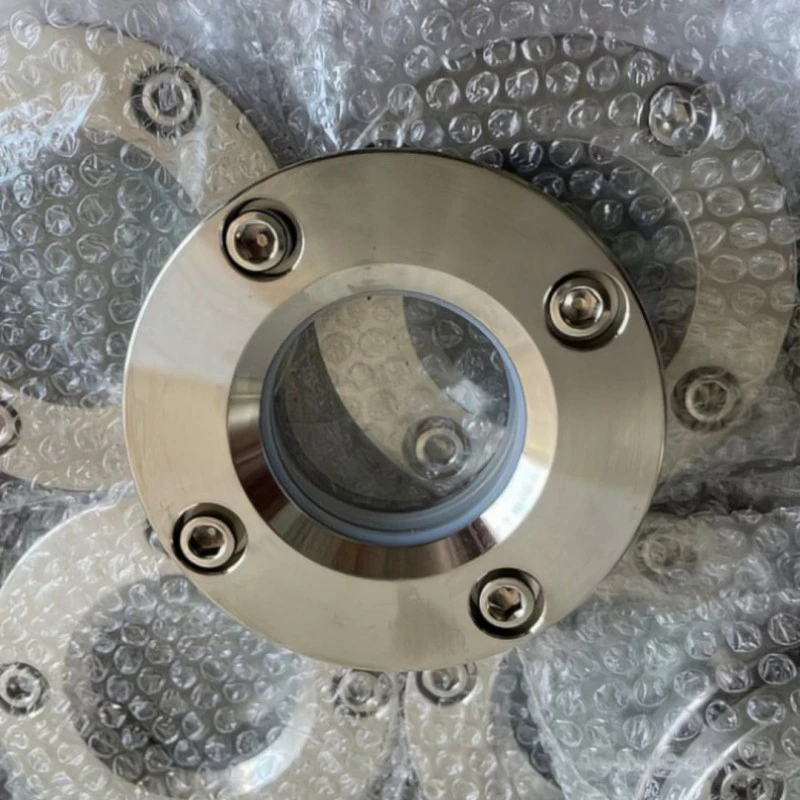

2、ring gear real shot picture

Jianing forging ring gear is completely upgraded, savoring the beauty of details.。

ring gear

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

3、Physical picture of ring gear

HD picture of Jianing ring gear,Thick teeth。

ring gear

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

4、ring gear application

ring gearIt has the functions of Transmit motion and power., Bear load and impact, Improve transmission accuracy and efficiency, Transmit motion and power. and Bear load and impact,widely used inmining machinery,Construction machinery and equipment,automobile making,petrochemical industry,mining machinery and other industries。

ring gear

5、Introduction of advantages of ring gear

The advantages of ring gear are as follows:

- High strength and toughness

- Improve production efficiency and material utilization rate

- High precision

- High precision

- High strength and toughness

The ring gear is manufactured by forging process, and the metal material undergoes plastic deformation at high temperature and high pressure, which eliminates internal defects such as pores and slag inclusion, and makes the material structure more dense. This compact structure makes the ring gear have higher strength and toughness, can bear greater load and impact, and improves the durability and reliability of the ring gear.

Forging process can usually form multiple ring gears at one time, and there are fewer subsequent processing steps, thus improving production efficiency. At the same time, due to the high utilization rate of materials in the forging process, the waste of materials is reduced and the production cost is reduced.

Forging process can ensure that the size accuracy and shape accuracy of the ring gear reach a high level.

Forging process can ensure that the size accuracy and shape accuracy of the ring gear reach a high level.

The ring gear is manufactured by forging process, and the metal material undergoes plastic deformation at high temperature and high pressure, which eliminates internal defects such as pores and slag inclusion, and makes the material structure more dense. This compact structure makes the ring gear have higher strength and toughness, can bear greater load and impact, and improves the durability and reliability of the ring gear.

ring gear

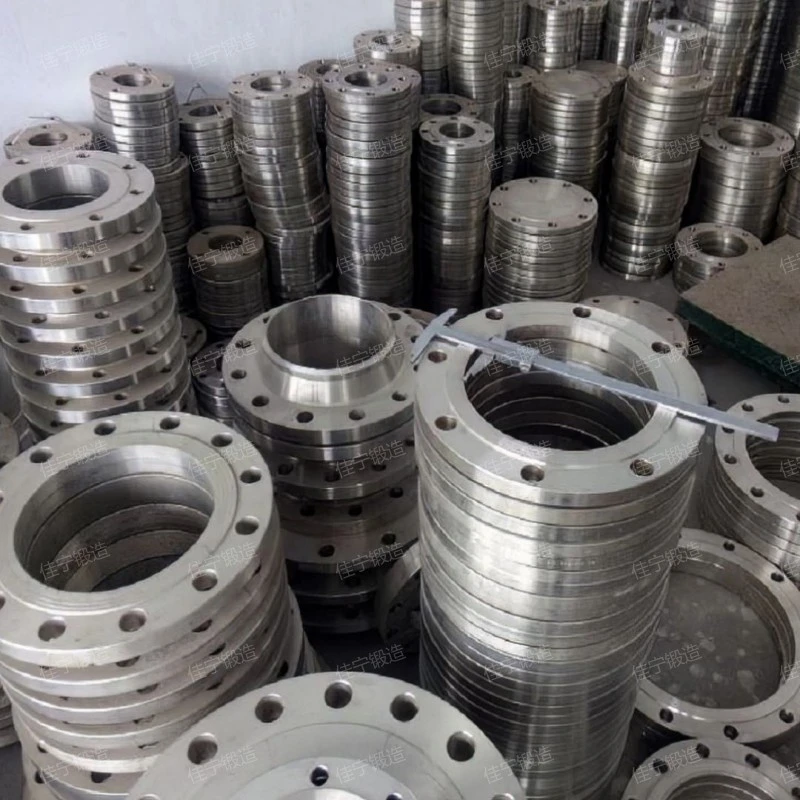

6、High-definition picture display of Jianing workshop

The finished products of the ring gear factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Jianing forging

The finished products of the ring gear factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

ring gearIt can be used for Improve transmission accuracy and efficiency, Transmit motion and power., Bear load and impact, Improve transmission accuracy and efficiency, Transmit motion and power., Bear load and impact and so on,is an important transmission mechanical device.。

Related recommendation

-

Introduction to Rectangular flat welding flange cover and flange advantages and features

2025-5-26 -

Introduction to Convex surface flat welding method steel flange cover and flange working principle

2025-5-26 -

Introduction to Carbon steel butt welded flange, flange specifications, model parameters

2025-5-26 -

What is a Stainless steel pressure vessel forging parts? Introduction to the advantages and characteristics of the forging

2025-5-26 -

Introduction to Double phase steel butt welding flange, advantages, characteristics and principles of flange

2025-5-26 -

Introduction to Strengthen the free forging of the ring, forging specifications, model parameters

2025-5-26 -

Introduction to Variable diameter pipe flange cover and flange working principle

2025-5-26 -

What is a Q345D alloy forged parts? Introduction to the Working Principle of forging

2025-5-26 -

法兰环锻件

2024-12-10 -

What is a Carbon steel flat welding reducing flange? Introduction to the Working Principle of flange

2025-5-26