Introduction to Concave-convex gear forgings, introduction to gear advantages and characteristics

Concave-convex gear forgingsis a mechanical element made by forging process, and its rim is designed with teeth, which can cooperate with other Concave-convex gear forgingss or racks to realize efficient transmission of power and movement.,Mainly used forImprove transmission accuracy and efficiency,Transmit motion and power.,Transmit motion and power.,Improve transmission accuracy and efficiency andBear load and impact,usually used in Construction machinery and equipment, automobile making, Construction machinery and equipment, mining machinery, petrochemical industry and other fields,it has the characteristics of High hardness, Strong bearing capacity, Can continuously mesh to transmit motion and power., High strength and toughness and Uniform material,Because of its excellent performance, it is widely used in aerospace, automobile, metallurgy, mining and other fields. Especially under extreme working conditions such as high load, high speed load and high temperature load, the advantages of forged Concave-convex gear forgingss are more prominent.、It can ensure that the size accuracy and shape accuracy of the Concave-convex gear forgings reach a higher level.、In forging process, the dimensional accuracy and shape accuracy of the Concave-convex gear forgings can be ensured through accurate die design and control. Compared with casting and other processes, the forging Concave-convex gear forgings has lower error and more accurate tooth profile, which is helpful to improve the stability and efficiency of the transmission system.、Forging process not only improves the strength and toughness of the Concave-convex gear forgings, but also helps to improve the mechanical properties of the Concave-convex gear forgings.、In the process of forging, the grain of metal material is refined and the hardness is improved, thus enhancing the wear resistance of the Concave-convex gear forgings. This enables the Concave-convex gear forgings to maintain good performance and prolong its service life during long-term use.。

1、Brief introduction of Concave-convex gear forgings

Concave-convex gear forgingsis a mechanical element made by forging process, with teeth on its rim, which can cooperate with other Concave-convex gear forgingss or racks to realize the transmission of power and movement.,is a Concave-convex gear forgings。

Concave-convex gear forgings

2、Concave-convex gear forgings application

Concave-convex gear forgingsIt has a wide range of uses, including Bear load and impact, Improve transmission accuracy and efficiency, Transmit motion and power., Bear load and impact and Improve transmission accuracy and efficiency,it can be used in petrochemical industry, mining machinery, automobile making, Construction machinery and equipment, mining machinery and other industries,Good wear resistance,Improve the overall mechanical properties.,The rim is toothed.,Strong bearing capacity,The tooth shape accuracy is high.,low in price。

Concave-convex gear forgings

3、Introduction of Concave-convex gear forgings characteristics

Concave-convex gear forgingsLong service life,Wide range of applications,Environmental protection advantage,Thick teeth,The tooth shape accuracy is high.,is an important part of transmission mechanism, and its rim is designed with teeth, which can continuously mesh to transmit motion and power.,has been favored by more and more customers.。

Concave-convex gear forgings

4、Introduction of advantages of Concave-convex gear forgings

Concave-convex gear forgingss have the following advantages.

- Improve the overall mechanical properties.

- Improve production efficiency and material utilization rate

- Good wear resistance

- High precision

- Long service life

Forging process not only improves the strength and toughness of the Concave-convex gear forgings, but also helps to improve the mechanical properties of the Concave-convex gear forgings. The improvement of these properties is helpful to improve the overall performance and stability of the transmission system.

Forging process can usually form multiple Concave-convex gear forgingss at one time, and there are fewer subsequent processing steps, thus improving production efficiency. At the same time, due to the high utilization rate of materials in the forging process, the waste of materials is reduced and the production cost is reduced.

In the process of forging, the grain of metal material is refined and the hardness is improved, thus enhancing the wear resistance of the Concave-convex gear forgings. This enables the Concave-convex gear forgings to maintain good performance and prolong its service life during long-term use.

In forging process, the dimensional accuracy and shape accuracy of the Concave-convex gear forgings can be ensured through accurate die design and control. Compared with casting and other processes, the forging Concave-convex gear forgings has lower error and more accurate tooth profile, which is helpful to improve the stability and efficiency of the transmission system.

Because of its strong bearing capacity, high precision and good wear resistance, the service life of the Concave-convex gear forgings is relatively long.

Concave-convex gear forgings

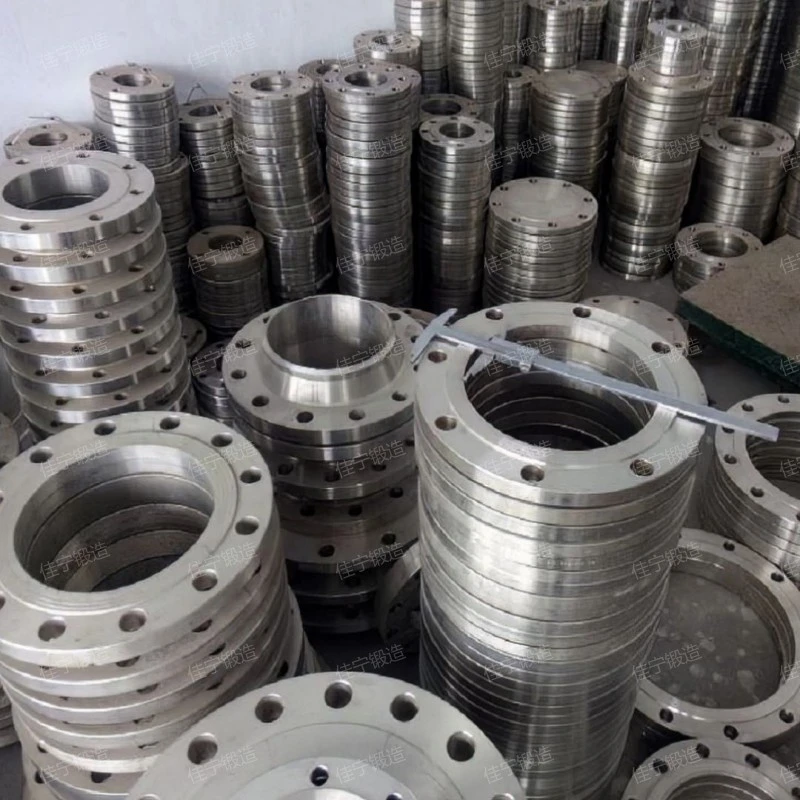

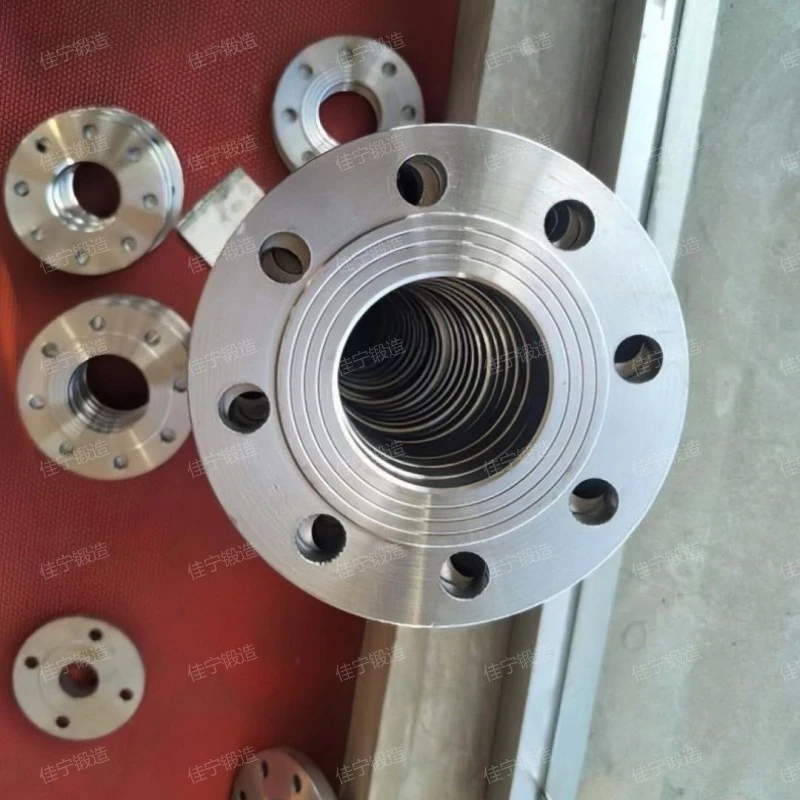

5、Concave-convex gear forgings real beat

Concave-convex gear forgings manufacturer, the product High definition shooting. In order to facilitate new and old customers to find satisfactory the product looks beautiful. more quickly, the following high-definition pictures are provided for reference.。

Concave-convex gear forgings

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

6、Introduction of Concave-convex gear forgings characteristics

Concave-convex gear forgingsfeatures include Strong bearing capacity, Good wear resistance, High strength, High strength and toughness and High shape accuracy,It is mostly used in Transmit motion and power., Transmit motion and power., Bear load and impact, Improve transmission accuracy and efficiency, Transmit motion and power., Bear load and impact and so on,is carefully developed by Jianing combined with advanced technology。

Concave-convex gear forgings

Concave-convex gear forgingsit is widely used in Construction machinery and equipment, automobile making, mining machinery, petrochemical industry and Construction machinery and equipment,It can be used for Transmit motion and power., Bear load and impact, Improve transmission accuracy and efficiency, Transmit motion and power., Bear load and impact, Improve transmission accuracy and efficiency and so on。

Related recommendation

-

What is a Manhole cover gear ring forgings? Introduction to the principle of ring gear structure

2025-5-26 -

What is a High pressure flange end cap forging parts? Introduction to the advantages and characteristics of forging functions

2025-5-26 -

What is a Flat welded steel pipe flange cover? Introduction to the advantages and characteristics of flange functions

2025-5-26 -

What is a Flat welded stainless steel flange with raised surface plate? Introduction to the advantages and characteristics of flange functions

2025-5-26 -

Introduction to PN16 flange and flange structure principle

2025-5-26 -

What is a Gear spline flange? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

What is a Plate welding stainless steel flange ring? How much is the price of the flange?

2025-5-26 -

Introduction to Flat welding flange ring with plate protruding surface, flange advantages, characteristics and principles

2025-5-26 -

Introduction to PN16 flange and flange structure principle

2025-5-26 -

Introduction to Low temperature steel butt welded flange cover, flange specifications, model parameters

2025-5-26