What is a integral flange? Introduction to the principle of flange structure

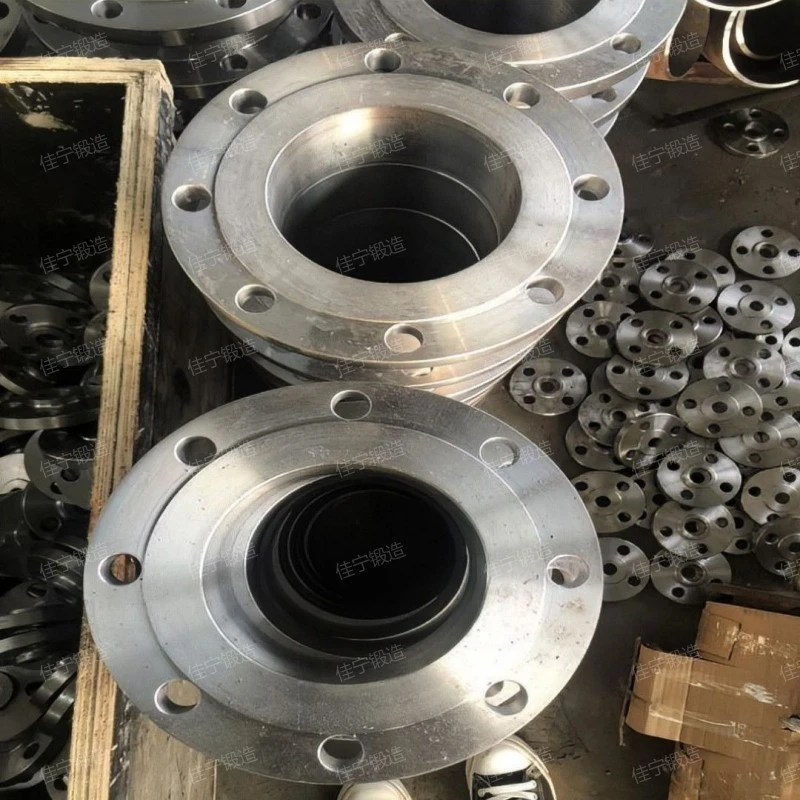

integral flangeflanges, gaskets and bolts are interconnected as a group to form a detachable connection of combined sealing structure.。The following is to introduce the integral flange:

1、Brief introduction of integral flange

integral flangeis a disk-shaped part.,is a kind of high quality and low price integral flange,it is widely used in Pipe connection, petrify, Air conditioning and refrigeration, Architectural and mechanical engineering and device attachment,Based on the principle of surface sealing, the uneven parts on the sealing surface are filled with gaskets to realize effective sealing, prevent fluid leakage and ensure safe and stable operation in the production process.、The design of the connection takes into account the factors such as disassembly, cleaning, overhaul and replacement, and has good operability, which reduces the difficulty and cost of installation.、The materials are varied, including carbon steel, stainless steel, alloy steel, etc. The appropriate materials can be selected according to the nature of the medium and working conditions to ensure the stability and corrosion resistance of the flange in different environments.、The manufacturing cost is relatively low, and the assembly is simple through fixing methods such as screws or nuts, so that the production efficiency is improved and the production cost is reduced.、Suitable connection methods can be selected according to different requirements, such as threaded connection and welding connection, so as to adapt to different working environments and technological requirements.,it is an ideal choice for customers to buy integral flange。

integral flange

2、integral flange characteristics

integral flangeHigh reliability,corrosion-resistant,high-temperature resistance,Good stability,High reliability,it is widely used infood processing,Shipbuilding industry,food processing,Pipe connection,petrify and other industries,the product looks atmospheric.,used for connection between pipe ends.,the advantage is Based on the principle of surface sealing, the uneven parts on the sealing surface are filled with gaskets to realize effective sealing, prevent fluid leakage and ensure safe and stable operation in the production process.、The materials are varied, including carbon steel, stainless steel, alloy steel, etc. The appropriate materials can be selected according to the nature of the medium and working conditions to ensure the stability and corrosion resistance of the flange in different environments.、The structural design makes it have strong bearing capacity and can adapt to the needs of high-pressure working environment. Excellent performance in pipeline connection of high temperature, high pressure and corrosive media, ensuring long-term stable operation of pipeline system.、Simple and convenient disassembly, suitable for equipment and pipelines that need to be cleaned, overhauled or replaced frequently, convenient for maintenance personnel to maintain, and reducing downtime and maintenance cost.、Suitable connection methods can be selected according to different requirements, such as threaded connection and welding connection, so as to adapt to different working environments and technological requirements.。

integral flange

3、integral flange use

The purpose of integral flange is introduced as follows:

- Pipe connection

- seal

- connect

- Convenient disassembly

- support

Used for conveying various liquids, gases and solid fluids, such as [commodity industry] and other fields.

Through the principle of surface sealing, it is ensured that the joint will not leak air, water or oil, thus ensuring the safe and reliable operation of the fluid conveying system.

integral flange can closely connect different pipelines, valves, pumps and containers to form a complete fluid conveying system.

The disassembly of the integral flange is simple and convenient, and it is suitable for equipment and pipelines that need to be cleaned, overhauled or replaced frequently, which is convenient for maintenance personnel to maintain.

As a supporting part of pipeline or equipment, it can improve the stability of pipeline or equipment and reduce problems such as vibration and deformation caused by stress.

integral flange

4、Functional advantages of integral flange

The advantages of integral flange are as follows:

- Wide selection of materials

- Easy maintenance

- easy installation

- Strong bearing capacity

- zonula occludens

The materials of the integral flange are varied, including carbon steel, stainless steel, alloy steel, etc. The appropriate materials can be selected according to the nature of the medium and working conditions to ensure the stability and corrosion resistance of the integral flange in different environments.

The integral flange is easy to disassemble, suitable for equipment and pipelines that need to be cleaned, overhauled or replaced frequently, which is convenient for maintenance personnel to maintain and reduces downtime and maintenance cost.

The design of integral flange connection takes into account such factors as disassembly, cleaning, overhaul and replacement, and has good operability, which reduces the installation difficulty and cost.

The structural design of the integral flange makes it have strong bearing capacity and can adapt to the needs of high-pressure working environment. Excellent performance in pipeline connection of high temperature, high pressure and corrosive media, ensuring long-term stable operation of pipeline system.

integral flange closely connect the two integral flange through bolts and other fasteners, forming a firm mechanical connection to ensure the stable connection between pipelines and equipment.

integral flange

5、How much is the integral flange?

The integral flange price is introduced as follows:

- cost of production

- Configuration level

- Product technology

- Service factor

- select a qualified person

When the integral flange is produced, the materials selected by different manufacturers will be different. Some manufacturers use high-quality materials, and the price will be relatively high, while some manufacturers use ordinary materials, and the price will be lower.

If the comprehensive configuration of the product is higher, the selling price of the product will be higher, otherwise the price will be lower, so there is a close relationship between the configuration level and the price.

The more advanced the technology, the higher the price will be, otherwise the product price will be low, and customers must pay attention to whether their own technology meets the production requirements when purchasing products.

Service factors always affect the sales price of products, and high-quality service will make customers have greater satisfaction and recognition. The service factors mainly include pre-sales service, in-sales service and after-sales service. For each stage of service, our company takes the price factor into account and makes a reasonable judgment between service and price, so that the integral flange price and service can meet the actual needs of customers.

Different manufacturers have different material selection standards. The better the quality of the selected materials, the more expensive the products will be. On the contrary, the prices will be low. However, to avoid customers being deceived, compare several products of the same specification and model before deciding to purchase.

integral flange

6、Why choose Jianing forging?

Choosing a suitable integral flange manufacturer requires comprehensive consideration of many aspects. First of all, we should examine the strength of manufacturers, including production capacity, R&D team and industry experience. Strong manufacturers can better ensure product supply and innovation ability. Secondly, product quality is the key, and it is evaluated by product certification, material selection and manufacturing process to ensure the durability of products. Product performance can not be ignored, so we should choose manufacturers with matching technical parameters, rich types and customized services according to actual needs. After-sales service is equally important. Professional and timely service team, perfect after-sales content and extensive service network can make users worry about nothing. In addition, market reputation is also an important reference. We can understand the reputation and status of manufacturers through customer evaluation, industry reputation and award-winning honor. Finally, it is necessary to analyze the price and cost performance, and on the premise of ensuring the quality and performance, choose a manufacturer with reasonable price and high cost performance, so as to purchase integral flange products that meet the demand and have good cost performance.。

Jianing forging

integral flangeis a popular integral flange,Commonly used inseal,Pipe connection,support,Convenient disassembly,connect and so on,The design of the connection takes into account the factors such as disassembly, cleaning, overhaul and replacement, and has good operability, which reduces the difficulty and cost of installation.、Simple and convenient disassembly, suitable for equipment and pipelines that need to be cleaned, overhauled or replaced frequently, convenient for maintenance personnel to maintain, and reducing downtime and maintenance cost.、The structural design makes it have strong bearing capacity and can adapt to the needs of high-pressure working environment. Excellent performance in pipeline connection of high temperature, high pressure and corrosive media, ensuring long-term stable operation of pipeline system.、The two flanges are tightly connected by bolts and other fasteners to form a firm mechanical connection, thus ensuring the stable connection between the pipeline and the equipment.、The materials are varied, including carbon steel, stainless steel, alloy steel, etc. The appropriate materials can be selected according to the nature of the medium and working conditions to ensure the stability and corrosion resistance of the flange in different environments.。

Related recommendation

-

Introduction to Short tube threaded flange and flange advantages and features

2025-5-26 -

What is a Flat welding concave convex sealing surface flange cover? Introduction to the principle of flange structure

2025-5-26 -

Introduction to 42CrMo4 free forging and forging advantages and features

2025-5-26 -

Introduction to Four hole blind plate, blind plate specifications, model parameters

2025-5-26 -

Introduction to Aluminum forgings and forging working principle

2025-5-26 -

Introduction to Ring sealing surface flange ring, introduction to flange function advantages and characteristics

2025-5-26 -

Introduction to Train wheel and wheel structure principle

2025-5-26 -

Introduction to Water and electricity main shaft forgings and forging structure principle

2025-5-26 -

Introduction to Q255C Carbon Steel Free Forging, how much is the price of the forging?

2025-5-26 -

Introduction to Circular forged parts and forging advantages and features

2025-5-26