Introduction to Crusher wheel forgings and wheel working principle

Crusher wheel forgingsis a workpiece or blank obtained by forging a metal blank. In the forging process, pressure is applied to the metal blank to cause plastic deformation, thus changing its mechanical properties. Crusher wheel forgings can be divided into cold forging, warm forging and hot forging according to the temperature of blank during processing.,it can be used in Heavy equipment, conveyor, Petrochemical general, mining machinery, Basic parts and other industries,features include Superior mechanical properties, Exquisite appearance, Excellent heat dissipation performance, Lightweight design and individualized design,Cheap and high quality。

1、Brief introduction of Crusher wheel forgings

Crusher wheel forgingsIs a workpiece or blank obtained by forging and deforming a metal blank.,it is an ideal choice for customers to buy Crusher wheel forgings。

Crusher wheel forgings

2、Crusher wheel forgings characteristics

Crusher wheel forgingsHigh strength,Strong corrosion resistance,Good physical properties,Good physical properties,Superior mechanical properties,In the process of forging, the metal streamline is retained, which makes the mechanical properties of forgings better than those of castings of the same material. In addition, the forging process can also eliminate the defects of as-cast porosity and optimize the microstructure, thus improving the service life and reliability of forgings.、This processing method can optimize the microstructure of metal, eliminate defects such as as as-cast porosity, improve the density and strength of materials, and make the Crusher wheel forgings have excellent mechanical properties and wear resistance.、It has good comprehensive mechanical properties and wear resistance, and can bear large loads and impacts.、In the process of forging, the metal streamline is retained, which makes the mechanical properties of forgings better than those of castings of the same material. In addition, the forging process can also eliminate the defects of as-cast porosity and optimize the microstructure, thus improving the service life and reliability of forgings.、This processing method can optimize the microstructure of metal, eliminate defects such as as as-cast porosity, improve the density and strength of materials, and make the Crusher wheel forgings have excellent mechanical properties and wear resistance.,It is mostly used in Provides stability and handling., Industrial application, Provides stability and handling., Vehicle movement, Adapt to different environments and conditions, Industrial application and so on,it is widely used in automobile, crane, Port machinery, Petrochemical general and conveyor,it is an ideal choice for customers to buy Crusher wheel forgings。

Crusher wheel forgings

3、Functional advantages of Crusher wheel forgings

Crusher wheel forgingss have the following advantages.

- Excellent heat dissipation performance

- Good physical properties

- Good anti-fatigue performance

- high tenacity

- individualized design

Crusher wheel forgingss are usually made of materials with good thermal conductivity, and the optimization of forging process makes them have excellent heat dissipation performance. In the process of long-term high-speed operation, it can effectively reduce the temperature of tires and braking systems, reduce the occurrence of thermal attenuation and improve driving safety.

During the forging process, the Crusher wheel forgings formed a fine particle structure and improved its physical properties, such as toughness and fatigue strength, which made the Crusher wheel forgings show excellent performance in practical application.

After forging, the micro defects in the Crusher wheel forgings are eliminated, and the structure is more uniform and dense, thus improving the fatigue resistance. This is especially important for equipment that needs to run for a long time and bear periodic loads.

In the process of forging, the metal blank undergoes plastic deformation under pressure, thus improving the toughness of the material. This makes the Crusher wheel forgings not easy to break when it bears impact, and enhances its durability and reliability.

Forging process has high flexibility and can manufacture Crusher wheel forgingss with various complex shapes. This makes the Crusher wheel forgings have more possibilities in appearance design and can meet the personalized needs of different users.

Crusher wheel forgings

4、Structural advantages of Crusher wheel forgings

The Crusher wheel forgings has the following structure

- wheel flange

- spoke

- hub

- wheel flange

- spoke

The shape and size of the rim have an important influence on the rolling performance, wear resistance and service life of the Crusher wheel forgings. In some designs, the rim may also include a tread part for contacting with the track to ensure the stable operation of the Crusher wheel forgings on the track.

The part connecting the hub and the rim plays the role of supporting and transmitting load.

Located in the center of the Crusher wheel forgings, it is the key part of the connection between the Crusher wheel forgings and the axle.

Located at the outer edge of the Crusher wheel forgings, it is the part where the Crusher wheel forgings contacts the road surface or installs tires.

There are various structural forms of spokes, such as straight spoke, oblique spoke, spoke plate, etc. The specific form depends on the purpose, load characteristics and lightweight requirements of the Crusher wheel forgings.

Crusher wheel forgings

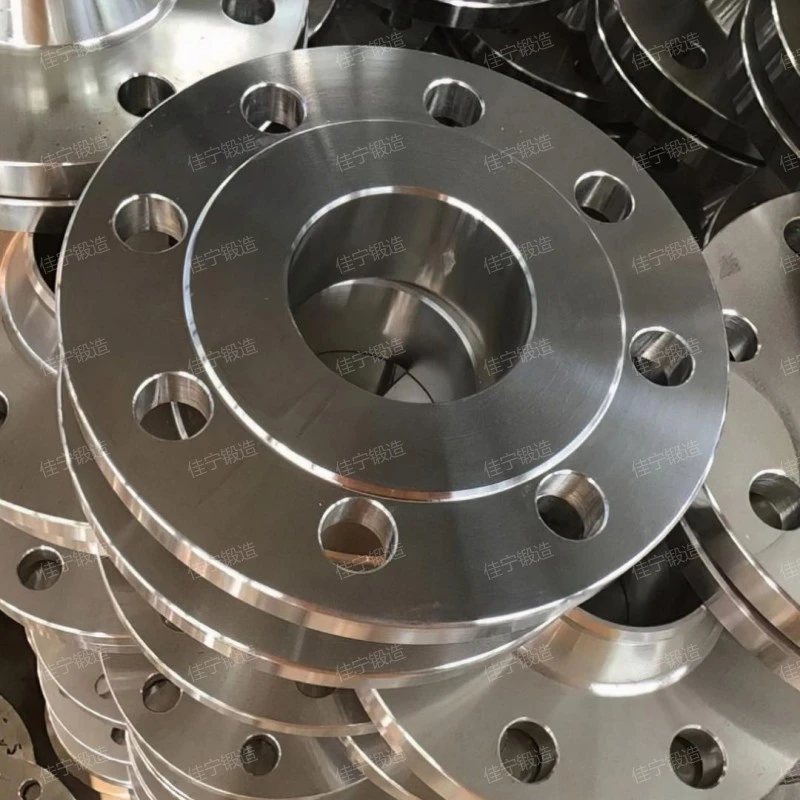

5、Crusher wheel forgings picture

The finished products of the Crusher wheel forgings factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Crusher wheel forgings

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

6、Brief introduction of Crusher wheel forgings

Crusher wheel forgingsis a Crusher wheel forgings part made by forging process.,it is widely used inHeavy equipment,mining machinery,Port machinery,crane,Petrochemical general and other industries,the product looks beautiful.,is a popular Crusher wheel forgings,is a Crusher wheel forgings newly developed by Jianing。

Crusher wheel forgings

Crusher wheel forgingsthe product looks atmospheric.,usually used in rolling stock, Heavy equipment, construction machinery, mining machinery, conveyor and other fields。

Related recommendation

-

Introduction to 14 inch flange ring and flange advantages and features

2025-5-26 -

What is a Flat welded tenon groove flange? Introduction to the Working Principle of flange

2025-5-26 -

Introduction to 35 # Carbon Steel Forged Parts, introduction to forging function advantages and characteristics

2025-5-26 -

What is a Q255C carbon steel forgings? Introduction to the advantages and characteristics of forging functions

2025-5-26 -

风机轴毛坯

2024-12-10 -

What is a 55Cr free forging? Introduction to the advantages and characteristics of the forging

2025-5-26 -

What is a Convex panel flat welded steel flange ring? Introduction to the Working Principle of flange

2025-5-26 -

What is a 316L threaded flange ring? Introduction to the principle of flange structure

2025-5-26 -

Introduction to Pipe thread connection flange cover, flange advantages, characteristics and principles

2025-5-26 -

What is a 30Cr free forging? forging specifications, models, and parameters

2025-5-26