What is a Stainless steel convex surface flat welding flange? Introduction to the advantages, characteristics, and principles of the flange

Stainless steel convex surface flat welding flangeis a disc-shaped part, which is mainly used to connect pipes, valves, pumps and containers. It tightly connects the two flanges through bolts and other fasteners to realize the sealing and connection of pipelines or equipment.,can be customized according to user's needs.。The following is to introduce the Stainless steel convex surface flat welding flange:

1、Brief introduction of Stainless steel convex surface flat welding flange

Stainless steel convex surface flat welding flangeis a key connecting and sealing component.,the product looks beautiful.,It has the functions of connect, seal, device attachment, support and Convenient disassembly,is a Stainless steel convex surface flat welding flange newly developed by Jianing。

Stainless steel convex surface flat welding flange

2、Stainless steel convex surface flat welding flange explanation video

You can buy Stainless steel convex surface flat welding flange according to your needs and show you product videos.。

Stainless steel convex surface flat welding flange

As you can see from the live video.,Shanxi jianing forging co., ltd it has the characteristics of Long service life, corrosion-resistant, High reliability, Good stability and high-temperature resistance。

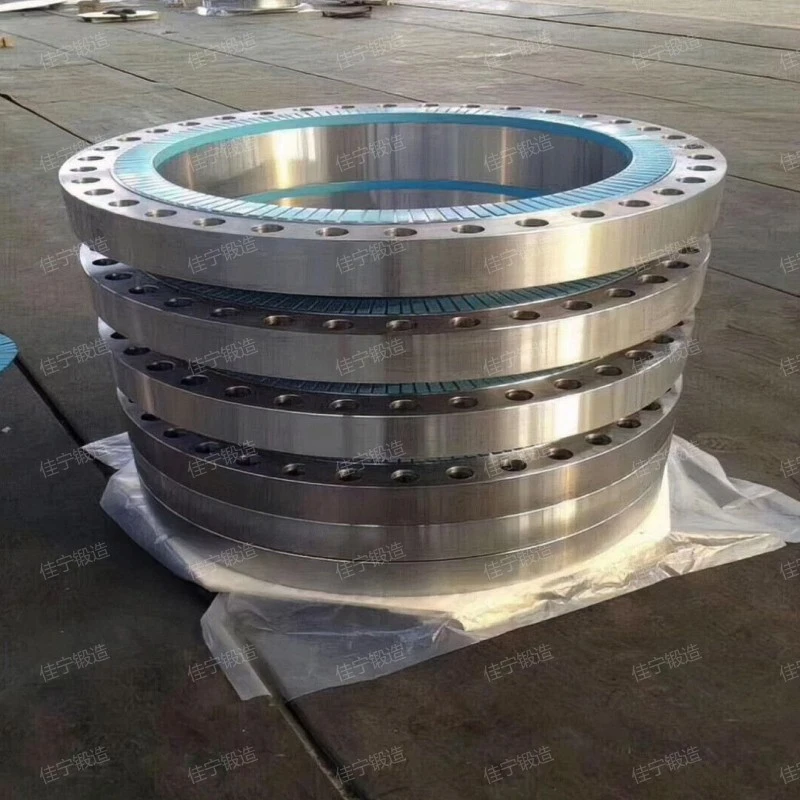

3、Stainless steel convex surface flat welding flange field real shot

HD pictures of Stainless steel convex surface flat welding flange of different specifications and models。

Stainless steel convex surface flat welding flange

Note: All the pictures in this article were taken by Jianing manufacturer.。

4、Stainless steel convex surface flat welding flange use

The purpose of Stainless steel convex surface flat welding flange is introduced as follows:

- seal

- Pipe connection

- support

- Convenient disassembly

- seal

Through the principle of surface sealing, it is ensured that the joint will not leak air, water or oil, thus ensuring the safe and reliable operation of the fluid conveying system.

Used for conveying various liquids, gases and solid fluids, such as [commodity industry] and other fields.

As a supporting part of pipeline or equipment, it can improve the stability of pipeline or equipment and reduce problems such as vibration and deformation caused by stress.

The disassembly of the Stainless steel convex surface flat welding flange is simple and convenient, and it is suitable for equipment and pipelines that need to be cleaned, overhauled or replaced frequently, which is convenient for maintenance personnel to maintain.

Through the principle of surface sealing, it is ensured that the joint will not leak air, water or oil, thus ensuring the safe and reliable operation of the fluid conveying system.

Stainless steel convex surface flat welding flange

5、Video analysis of Stainless steel convex surface flat welding flange

On-site aerial photography of Stainless steel convex surface flat welding flange。

Stainless steel convex surface flat welding flange

As you can see from the live video.,Jianing forging is a disc-shaped part, which is mainly used to connect pipes, valves, pumps and containers.。

6、Stainless steel convex surface flat welding flange quotation

The Stainless steel convex surface flat welding flange price is introduced as follows:

- product quality

- raw material

- product costs

- Manufacturer's sales model

- Brand strength

Quality is one of the fundamental and important factors that affect the price. Usually, the better the quality of the Stainless steel convex surface flat welding flange, the higher its price, and the quality is mainly affected by the manufacturing process, raw material materials, workers' experience and other factors. Therefore, if customers want to buy products with better quality, they can conduct on-the-spot visits to the product manufacturers to learn more about the scale, manufacturing process and production capacity of the manufacturers, so as to comprehensively judge the quality of the products.

The quality of material selection is one of the main factors that directly affect the Stainless steel convex surface flat welding flange. If the quality of material selection is better, the price may be more expensive. Therefore, customers must first understand the quality of material selection before purchasing products, and then compare whether the quality and price match.

The production cost is mainly the purchase of raw materials. Jianing forging attaches great importance to the purchase of raw materials to ensure the comprehensive quality of products. Only excellent raw materials can produce excellent products, and the input cost of raw materials has a direct relationship with the formulation of product prices. Under the premise of ensuring excellent product performance, Jianing strives to reduce the input cost of products, and customers are very satisfied with this.

Jianing forging Stainless steel convex surface flat welding flange manufacturer is a professional Stainless steel convex surface flat welding flangemanufacturer, the manufacturer produces and sells products directly to customers, without the influence of the price difference between middlemen. The market price of the manufacturer's products is the ex-factory price, and the Stainless steel convex surface flat welding flange price is also low.

At present, there are various brands of Stainless steel convex surface flat welding flange in Xinzhou. The performance, quality and after-sales of products under different brands are different, and the prices of Stainless steel convex surface flat welding flange are different.

Stainless steel convex surface flat welding flange

Stainless steel convex surface flat welding flangeit is widely used inmedicine,food processing,petrify,Architectural and mechanical engineering,Shipbuilding industry and other industries,Simple and convenient disassembly, suitable for equipment and pipelines that need to be cleaned, overhauled or replaced frequently, convenient for maintenance personnel to maintain, and reducing downtime and maintenance cost.、Suitable connection methods can be selected according to different requirements, such as threaded connection and welding connection, so as to adapt to different working environments and technological requirements.、The manufacturing cost is relatively low, and the assembly is simple through fixing methods such as screws or nuts, so that the production efficiency is improved and the production cost is reduced.、The structural design makes it have strong bearing capacity and can adapt to the needs of high-pressure working environment. Excellent performance in pipeline connection of high temperature, high pressure and corrosive media, ensuring long-term stable operation of pipeline system.、Based on the principle of surface sealing, the uneven parts on the sealing surface are filled with gaskets to realize effective sealing, prevent fluid leakage and ensure safe and stable operation in the production process.。

Related recommendation

-

What is a Large shaft forging parts? Introduction to the advantages, characteristics, and principles of the forging

2025-5-26 -

What is a Bottom forging of cylinder? Introduction to the advantages and characteristics of the forging

2025-5-26 -

Introduction to Q345E butt welded flange plate, flange specifications, model parameters

2025-5-26 -

钻杆轴锻件

2024-12-10 -

Introduction to Welding hole plate flange cover, flange specifications, model parameters

2025-5-26 -

Introduction to Four hole blind plate, blind plate specifications, model parameters

2025-5-26 -

What is a Flange cylinder forging? Introduction to the advantages and characteristics of the forging

2025-5-26 -

What is a 304 butt welded flange cover? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

Introduction to National standard metal free forging, introduction to forging advantages and characteristics

2025-5-26 -

Introduction to Embedded threaded flange, flange advantages, characteristics and principles

2025-5-26