Introduction to Q345d flat welded flange ring and flange working principle

Q345d flat welded flange ringis a part that connects shaft to shaft.。The following is to introduce the Q345d flat welded flange ring:

1、Brief introduction of Q345d flat welded flange ring

Q345d flat welded flange ringflange used on the inlet and outlet of equipment, used for the connection between two equipment.,Widely used in support, Pipe connection, seal, seal and Convenient disassembly,is a Q345d flat welded flange ring,is based on Jianing forging is an advanced Q345d flat welded flange ring developed by our company in combination with the actual situation of the industry。

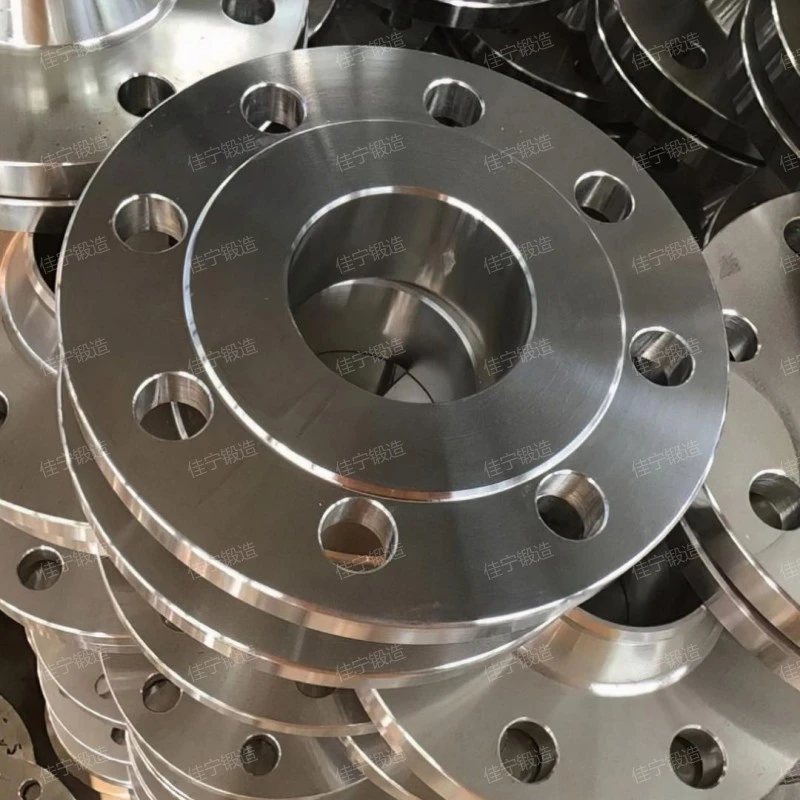

Q345d flat welded flange ring

2、Q345d flat welded flange ring HD real shot

Speak directly with facts on the spot。

Q345d flat welded flange ring

As you can see from the live video.,Jianing the product looks atmospheric.。

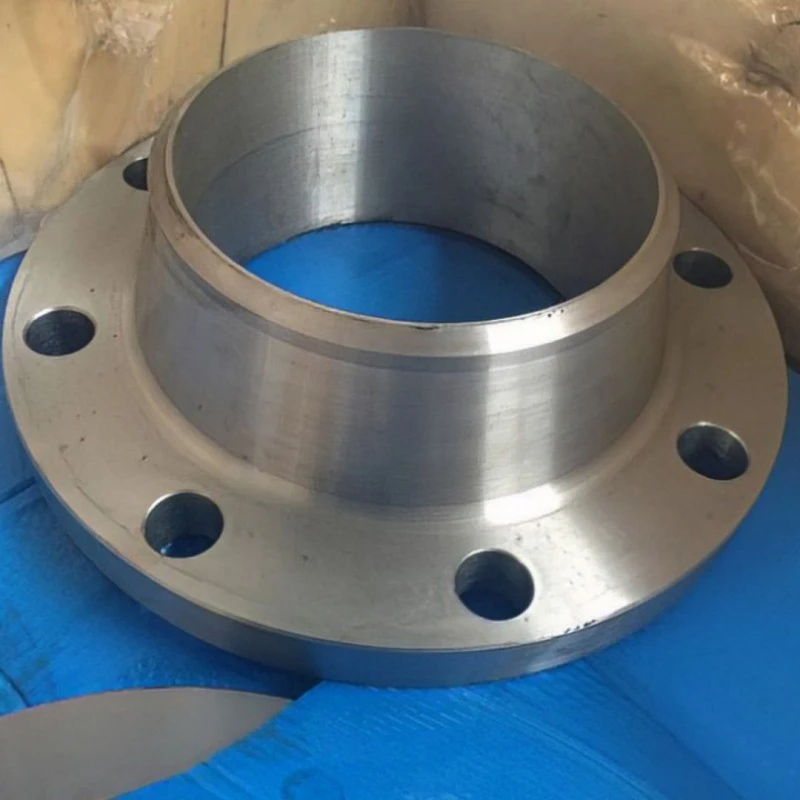

3、Q345d flat welded flange ring characteristics

Q345d flat welded flange ringHigh reliability,high-temperature resistance,Good stability,Good stability,high-temperature resistance。

Q345d flat welded flange ring

4、Functional advantages of Q345d flat welded flange ring

The advantages of Q345d flat welded flange ring are as follows:

- economy

- Good sealing performance

- Strong bearing capacity

- economy

- Generality

The manufacturing cost of the Q345d flat welded flange ring is relatively low, and it is simple to assemble by fixing methods such as screws or nuts, which improves the production efficiency and reduces the production cost.

The Q345d flat welded flange ring adopts the principle of surface sealing, and the uneven parts on the sealing surface are filled with gaskets to realize effective sealing, prevent fluid leakage and ensure safe and stable operation in the production process.

The structural design of the Q345d flat welded flange ring makes it have strong bearing capacity and can adapt to the needs of high-pressure working environment. Excellent performance in pipeline connection of high temperature, high pressure and corrosive media, ensuring long-term stable operation of pipeline system.

The manufacturing cost of the Q345d flat welded flange ring is relatively low, and it is simple to assemble by fixing methods such as screws or nuts, which improves the production efficiency and reduces the production cost.

The Q345d flat welded flange ring adopts standardized design, conforms to the standards and specifications of many countries and regions, and can be used in conjunction with various brands of equipment and pipelines, thus improving the interchangeability and versatility of equipment.

Q345d flat welded flange ring

5、Q345d flat welded flange ring use

The purpose of Q345d flat welded flange ring is introduced as follows:

- seal

- connect

- support

- Pipe connection

- device attachment

Through the principle of surface sealing, it is ensured that the joint will not leak air, water or oil, thus ensuring the safe and reliable operation of the fluid conveying system.

Q345d flat welded flange ring can closely connect different pipelines, valves, pumps and containers to form a complete fluid conveying system.

As a supporting part of pipeline or equipment, it can improve the stability of pipeline or equipment and reduce problems such as vibration and deformation caused by stress.

Used for conveying various liquids, gases and solid fluids, such as [commodity industry] and other fields.

Connect all kinds of equipment and machinery, such as engines, pumps, compressors, heat exchangers, air conditioning equipment, etc.

Q345d flat welded flange ring

6、Brief introduction of Q345d flat welded flange ring

Q345d flat welded flange ringflanges, gaskets and bolts are interconnected as a group to form a detachable connection of combined sealing structure.,be loved by our customers.。

Q345d flat welded flange ring

Q345d flat welded flange ringHigh reliability,corrosion-resistant,Long service life,Good stability,high-temperature resistance,The two flanges are tightly connected by bolts and other fasteners to form a firm mechanical connection, thus ensuring the stable connection between the pipeline and the equipment.、The manufacturing cost is relatively low, and the assembly is simple through fixing methods such as screws or nuts, so that the production efficiency is improved and the production cost is reduced.、The design of the connection takes into account the factors such as disassembly, cleaning, overhaul and replacement, and has good operability, which reduces the difficulty and cost of installation.、The materials are varied, including carbon steel, stainless steel, alloy steel, etc. The appropriate materials can be selected according to the nature of the medium and working conditions to ensure the stability and corrosion resistance of the flange in different environments.、Suitable connection methods can be selected according to different requirements, such as threaded connection and welding connection, so as to adapt to different working environments and technological requirements.,is a key connecting and sealing component.。

Related recommendation

-

Introduction to DN1600 flange plate, advantages, characteristics and principles of flange

2025-5-26 -

Introduction to Flat welded square flange ring, flange specifications, model parameters

2025-5-26 -

Introduction to Gear with hole, how much is the price of the gear?

2025-5-26 -

What is a Aluminum alloy bearing forged parts? Introduction to the advantages and characteristics of the forging

2025-5-26 -

What is a Wheel axle free forging? How much is the price of the forging?

2025-5-26 -

What is a 304 butt welded flange ring? Introduction to the Working Principle of flange

2025-5-26 -

What is a D-type tube plate? How much is the price of the tube sheet?

2025-5-26 -

What is a Taiwan level forged ring parts? Introduction to the advantages, characteristics, and principles of the forging

2025-5-26 -

Introduction to 8-inch flange ring, introduction to flange function advantages and characteristics

2025-5-26 -

What is a PL steel flat welded pipe flange? Introduction to the advantages and characteristics of the flange

2025-5-26