Introduction to Boiler suspension rod free forging and forging working principle

Boiler suspension rod free forgingis the metal that exerts pressure to shape the required shape or appropriate compression through plastic deformation.,is a kind of high quality and low price Boiler suspension rod free forging,it has the characteristics of Good mechanical properties, High productivity, High productivity, Great forging flexibility and high-precision,widely used in pressure vessel, rail traffic, automobile, manufacturing industry, shipping and other fields,Cheap and high quality。

1、Brief introduction of Boiler suspension rod free forging

Boiler suspension rod free forgingrefers to the workpiece or blank obtained by forging metal blank.,is a kind of Boiler suspension rod free forging manufactured by Jianing forging。

Boiler suspension rod free forging

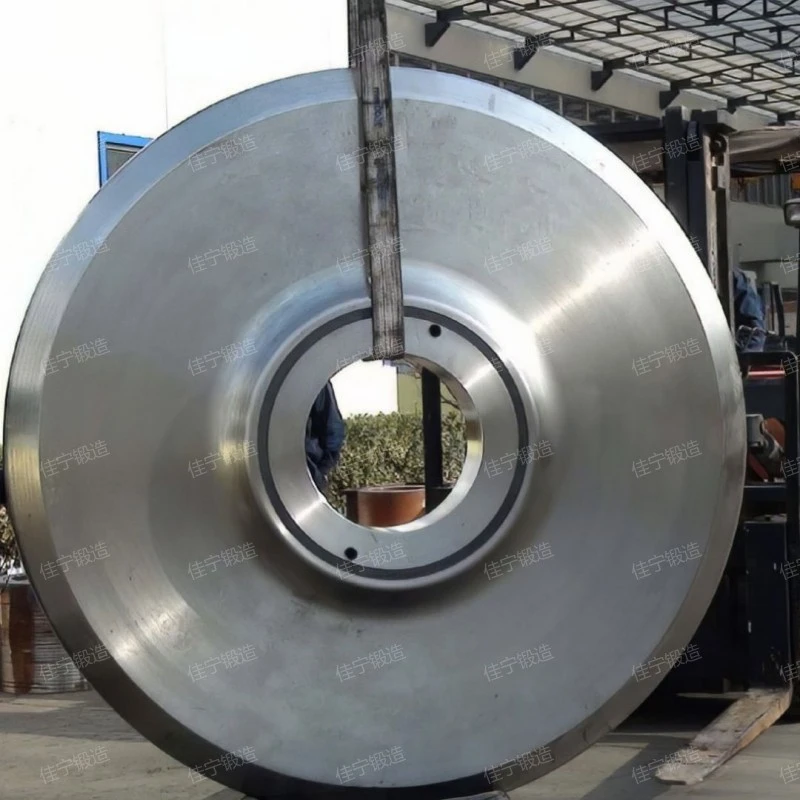

2、Boiler suspension rod free forging work site real shot

The styles and designs of Boiler suspension rod free forging are diverse, and the specifications and models can be tailored according to users' needs, providing high-definition drawings for our customers' reference.。

Boiler suspension rod free forging

Note: All the pictures in this article were taken by Jianing manufacturer.。

3、Functional advantages of Boiler suspension rod free forging

Boiler suspension rod free forgings have the following advantages.

- Meet the requirements of complex working conditions

- Eliminate internal defects

- high tenacity

- high-intensity

- High dimensional accuracy

The Boiler suspension rod free forging has excellent mechanical properties and structural integrity, which can meet the use requirements under complex working conditions and ensure the long-term stable operation of the equipment.

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the Boiler suspension rod free forging.

The fiber structure of the Boiler suspension rod free forging is reasonably distributed, which improves the toughness of the material and enables the Boiler suspension rod free forging to bear greater impact force and alternating stress.

Through forging, the internal structure of the metal is denser and the grain is refined, thus improving the strength of the material. Hot forging promotes crystallization and grain refinement, which enables materials to achieve the greatest possible strength and consistency, and reduces the variation between parts.

In the forging process of Boiler suspension rod free forging, high dimensional accuracy and shape accuracy can be obtained through the precise forming of dies.

Boiler suspension rod free forging

4、Boiler suspension rod free forging characteristics

Boiler suspension rod free forgingGood mechanical properties,Save raw materials,Can bear large impact force or heavy load.,high tenacity,high-intensity,is based on Jianing forging is a Boiler suspension rod free forging newly developed by Jianing。

Boiler suspension rod free forging

5、On-site real shot of Boiler suspension rod free forging

High-definition pictures at a glance, beautifully designed atmosphere, stylish, extraordinary temperament, for your visit.。

Boiler suspension rod free forging

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

6、Brief introduction of Boiler suspension rod free forging

Boiler suspension rod free forgingis a workpiece or blank obtained by forging and deforming a metal blank.。

Boiler suspension rod free forging

Boiler suspension rod free forgingfeatures include High production efficiency, Good anti-fatigue performance, Light weight, High productivity and Light weight,is a Boiler suspension rod free forging。

Related recommendation

-

Introduction to Flat welding special-shaped flange plate, introduction to flange function advantages and characteristics

2025-5-26 -

What is a Plate flat welding concave convex flange ring? Introduction to the advantages and characteristics of the flange

2025-5-26 -

Introduction to Free forging of petrochemical equipment cylinder and forging working principle

2025-5-26 -

What is a 1Cr5Mo flat welding flange plate? Introduction to the advantages and characteristics of flange functions

2025-5-26 -

What is a Forging parts of rudder stock? Introduction to the advantages, characteristics, and principles of the forging

2025-5-26 -

Introduction to Type A flat welding pressure vessel flange and flange working principle

2025-5-26 -

Introduction to 16MnD alloy forged parts and forging structure principle

2025-5-26 -

What is a Clamping ring gear forgings? Introduction to the principle of ring gear structure

2025-5-26 -

What is a Ring type free forging? How much is the price of the forging?

2025-5-26 -

What is a Convex concave flange? Introduction to the principle of flange structure

2025-5-26