Introduction to Forging parts for rudder stock and forging structure principle

Forging parts for rudder stockplastic deformation is made to obtain forgings with certain shapes and mechanical properties.,Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Forging parts for rudder stock can be improved.、After forging, its structure and mechanical properties can be improved.,it is widely used inmanufacturing industry,shipping,energy,automobile,rail traffic and other industries,the product looks beautiful.,was developed and designed by Jianing。

1、Brief introduction of Forging parts for rudder stock

Forging parts for rudder stockis a part or blank in which a metal blank is plastically deformed under pressure to obtain the required shape, size and performance.,high tenacity,Light weight,Great forging flexibility,Can bear large impact force or heavy load.,Light weight,the product looks atmospheric.,is carefully developed by Jianing combined with advanced technology。

Forging parts for rudder stock

2、Forging parts for rudder stock characteristics

Forging parts for rudder stockthe main features are high-intensity, High productivity, High production efficiency, Save raw materials and high-precision,it is widely used in war industry, manufacturing industry, rail traffic, metallurgy, energy and other industries,the advantage is Forging can eliminate metal porosity and holes, and improve the mechanical properties of Forging parts for rudder stock.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、After forging, its structure and mechanical properties can be improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.。

Forging parts for rudder stock

3、Introduction of Forging parts for rudder stock characteristics

Forging parts for rudder stockit has the characteristics of Good anti-fatigue performance, high tenacity, Great forging flexibility, Good mechanical properties and Can bear large impact force or heavy load.。

Forging parts for rudder stock

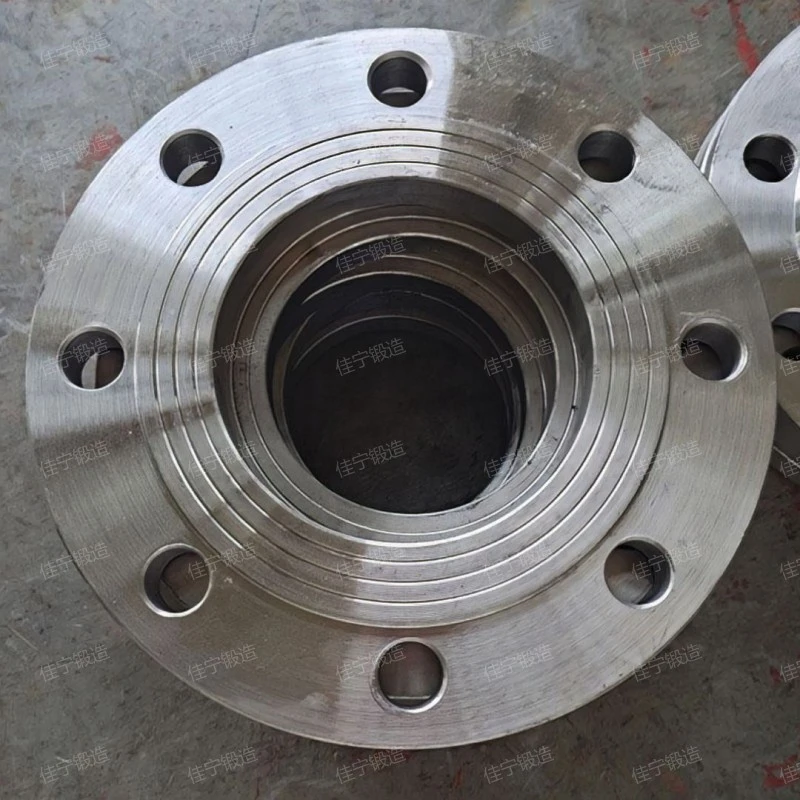

4、Forging parts for rudder stock field real shot

Provide high-definition Forging parts for rudder stock real shot, a variety of specifications and models for customers to visit.。

Forging parts for rudder stock

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

5、Forging parts for rudder stock price

The Forging parts for rudder stock price is introduced as follows:

- Different regions

- Low cost of raw materials

- Self quality

- After-sales service level

- region

The price of Forging parts for rudder stock in Shanxi Xinzhou is much lower than that in other regions, and Jianing forging is a manufacturer specializing in the production of different products not only pays attention to the quality of products, but also pays more attention to customer satisfaction, and always adopts the marketing strategy of small profits but quick turnover to make the Forging parts for rudder stock price positioning more reasonable, low-cost and economical.

When it comes to cost, I believe everyone has heard the saying "You get what you want for a price", which shows that the upfront cost of a product is directly proportional to its value. The upfront cost is high, the value is high, the quality is good, and the price is naturally high. The less the cost is, the lower the price is, and the quality is not good.

Quality is the key factor to determine the price. A high-quality product requires a lot of manpower, material resources and raw materials, so the manufacturing cost of the product is high. Therefore, the price of high-quality products is high. On the contrary, the price of Forging parts for rudder stock is low.

Service factors always affect the sales price of products, and high-quality service will make customers have greater satisfaction and recognition. The service factors mainly include pre-sales service, in-sales service and after-sales service. For each stage of service, our company takes the price factor into account and makes a reasonable judgment between service and price, so that the Forging parts for rudder stock price and service can meet the actual needs of customers.

Different provinces and regions have different consumption levels, different market positioning and different prices.

Forging parts for rudder stock

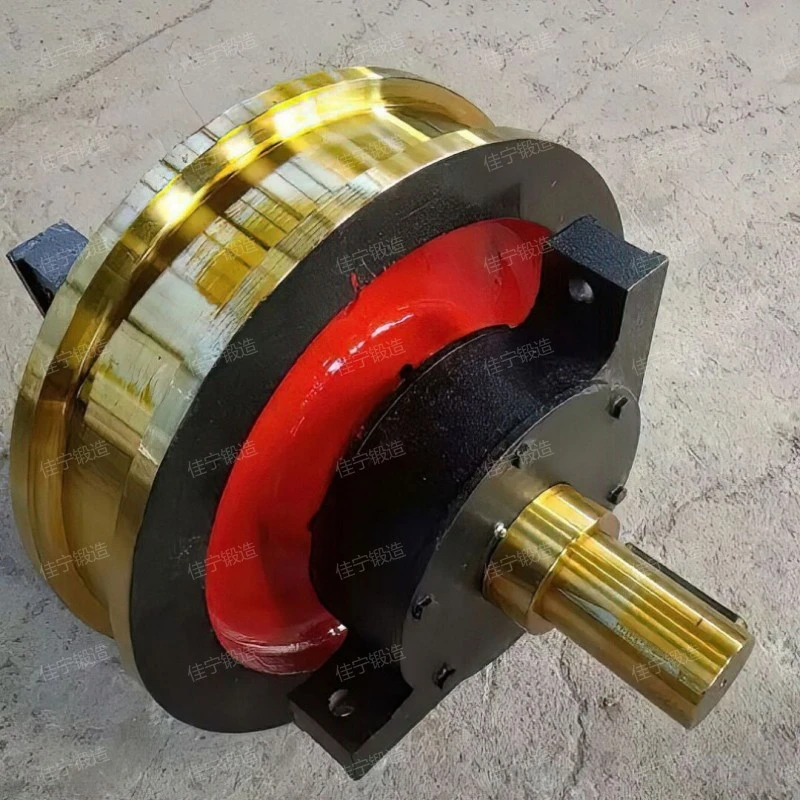

6、Jianing workshop real shot

The finished products of the Forging parts for rudder stock factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Jianing forging

The finished products of the Forging parts for rudder stock factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Forging parts for rudder stockis a common Forging parts for rudder stock,it is widely used in war industry, shipping, power, pressure vessel and automobile。

Related recommendation

-

What is a Round pancake forging parts? Introduction to the advantages and characteristics of forging functions

2025-5-26 -

Introduction to DN2600 flange cover, flange advantages, characteristics and principles

2025-5-26 -

Introduction to Irregular flat welding flange and flange working principle

2025-5-26 -

What is a 316 blind flange? Introduction to the principle of blind plate structure

2025-5-26 -

What is a Convex welding flange plate? Introduction to the advantages and characteristics of the flange

2025-5-26 -

What is a High strength steel forged parts? forging specifications, models, and parameters

2025-5-26 -

Introduction to Half shaft sleeve forging parts and forging working principle

2025-5-26 -

Introduction to Flat welded B-type flange and flange structure principle

2025-5-26 -

Introduction to Travelling wheel, introduction to wheel function advantages and characteristics

2025-5-26 -

Introduction to Flat welding flange with plate protruding surface, flange specifications, model parameters

2025-5-26