Introduction to Mold steel shaft forging parts, how much is the price of the forging?

Mold steel shaft forging partsplastic deformation is made to obtain forgings with certain shapes and mechanical properties.,the product looks atmospheric.,After forging, its structure and mechanical properties can be improved.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Mold steel shaft forging parts can be improved.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Mold steel shaft forging parts.、After forging, its structure and mechanical properties can be improved.,is a Mold steel shaft forging parts,it is widely used inrail traffic,shipping,manufacturing industry,metallurgy,automobile and other industries。The following is to introduce the Mold steel shaft forging parts:

1、Brief introduction of Mold steel shaft forging parts

Mold steel shaft forging partsis the metal that exerts pressure to shape the required shape or appropriate compression through plastic deformation.,features include Great forging flexibility, Save raw materials, Good anti-fatigue performance, Can bear large impact force or heavy load. and high-intensity。

Mold steel shaft forging parts

2、Video analysis of Mold steel shaft forging parts

The following is the live video of Mold steel shaft forging parts designed and produced by Jianing for users, from which we can see the the advantage is Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Mold steel shaft forging parts can be improved.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties. of Mold steel shaft forging parts.。

Mold steel shaft forging parts

As you can see from the live video.,Shanxi jianing forging co., ltd Can bear large impact force or heavy load.,Good mechanical properties,Light weight,High production efficiency,Good anti-fatigue performance。

3、Introduction of Mold steel shaft forging parts characteristics

Mold steel shaft forging partsthe main features are high-precision, high tenacity, Great forging flexibility, High productivity and Save raw materials,usually used in pressure vessel, manufacturing industry, metallurgy, rail traffic, power and other fields。

Mold steel shaft forging parts

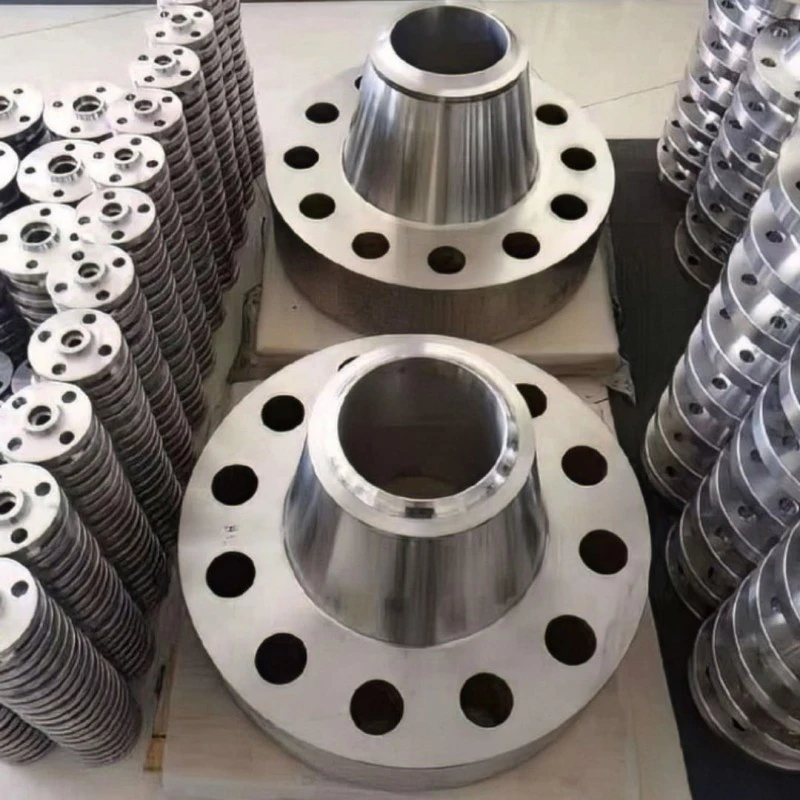

4、Mold steel shaft forging parts HD picture real shot

Details of Jianing forging Mold steel shaft forging parts,the product looks beautiful.。

Mold steel shaft forging parts

Note: All the pictures in this article were taken by Jianing manufacturer.。

5、How much is the Mold steel shaft forging parts?

The Mold steel shaft forging parts price is introduced as follows:

- quality factor

- Model specification

- raw material

- Reasonable cost

- Product technology

The condition of the product itself has a great influence on its price, and the cost of the product with excellent quality is higher, which will lead to the increase of the selling price of the product. Therefore, this is an important factor that causes the price fluctuation and change of the Mold steel shaft forging parts.

The same product, even with different specifications and models and different configurations, has different costs, so the price will be different.

The raw materials used by different manufacturers will also be different. The better the raw materials, the better the quality and performance of the products and the higher the price. On the contrary, the products made of ordinary materials have low production costs and much lower prices.

The manufacturing cost has a great influence on the price. There are many cost factors, including the purchase of raw materials and the quality of products. These factors are all cost inputs. Jianing forging has made a strong balance between the cost input and the sales price, so that the quality of our products can be guaranteed and the comprehensive price of products can reach the degree of customer satisfaction.

Each customer needs different products, wants to achieve different purposes, and has different product technical design. The higher or more advanced the technical requirements, the more the product cost will be, and the price will increase with the increase of cost. On the contrary, the price will be cheaper.

Mold steel shaft forging parts

6、Real-time shooting in Jianing forging's production workshop

The finished products of the Mold steel shaft forging parts factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Jianing

The finished products of the Mold steel shaft forging parts factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Mold steel shaft forging partsit is widely used in power, pressure vessel, war industry, shipping, war industry and other industries,the product looks atmospheric.,refers to the workpiece or blank obtained by forging metal blank. In the process of forging, the metal blank is plastically deformed under the pressure of forging hammer, press and other equipment, and then its shape, size and organizational structure are changed to meet specific use requirements.。

Related recommendation

-

What is a Quick release ring forging? Introduction to the advantages and characteristics of forging functions

2025-5-26 -

What is a Q235D Carbon Steel Forging Parts? Introduction to the Working Principle of forging

2025-5-26 -

What is a Conical forged parts? Introduction to the principle of forging structure

2025-5-26 -

What is a Internal gear ring forgings? Introduction to the advantages and characteristics of ring gear functions

2025-5-26 -

What is a Q275B carbon steel forgings? Introduction to the advantages and characteristics of forging functions

2025-5-26 -

盲板

2024-12-10 -

What is a SO welded flange cover? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

What is a Flat welding concave convex flange? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

Introduction to 9Cr18 forging and forging working principle

2025-5-26 -

Introduction to Welding variable diameter flange ring and flange structure principle

2025-5-26