Introduction to Wind turbine shaft free forging, forging advantages, characteristics and principles

Wind turbine shaft free forgingis the metal that exerts pressure to shape the required shape or appropriate compression through plastic deformation.,be loved by our customers.。The following is to introduce the Wind turbine shaft free forging:

1、Brief introduction of Wind turbine shaft free forging

Wind turbine shaft free forgingrefers to the workpiece or blank obtained by forging metal blank.,is a Wind turbine shaft free forging,the product looks beautiful.,it has been widely used in metallurgy, automobile, rail traffic, manufacturing industry, automobile and other industries,the main features are High productivity, Good anti-fatigue performance, Save raw materials, Can bear large impact force or heavy load. and High productivity。

Wind turbine shaft free forging

2、Wind turbine shaft free forging advantage

The advantages of Wind turbine shaft free forging are as follows:

- Eliminate internal defects

- Perfect quality assurance system

- Optimizing structural design

- Replace other processing methods

- Meet the requirements of complex working conditions

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the Wind turbine shaft free forging.

In the process of Wind turbine shaft free forging production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the Wind turbine shaft free forging.

On the premise of ensuring the design strength, through reasonable structural design, the Wind turbine shaft free forging can be lighter than the casting, thus reducing the overall weight of the machine or equipment and reducing energy consumption and cost.

In some cases, Wind turbine shaft free forging can replace parts produced by other processing methods (such as casting, welding, etc.), thus simplifying the production process and improving production efficiency.

The Wind turbine shaft free forging has excellent mechanical properties and structural integrity, which can meet the use requirements under complex working conditions and ensure the long-term stable operation of the equipment.

Wind turbine shaft free forging

3、Wind turbine shaft free forging video live broadcast

The following is the live video of Wind turbine shaft free forging designed and produced by Jianing for users, from which we can see the Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Wind turbine shaft free forging.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Wind turbine shaft free forging can be improved.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved. of Jianing forgingProduction and processing的Wind turbine shaft free forging.。

Wind turbine shaft free forging

As you can see from the live video.,Jianing is a common Wind turbine shaft free forging。

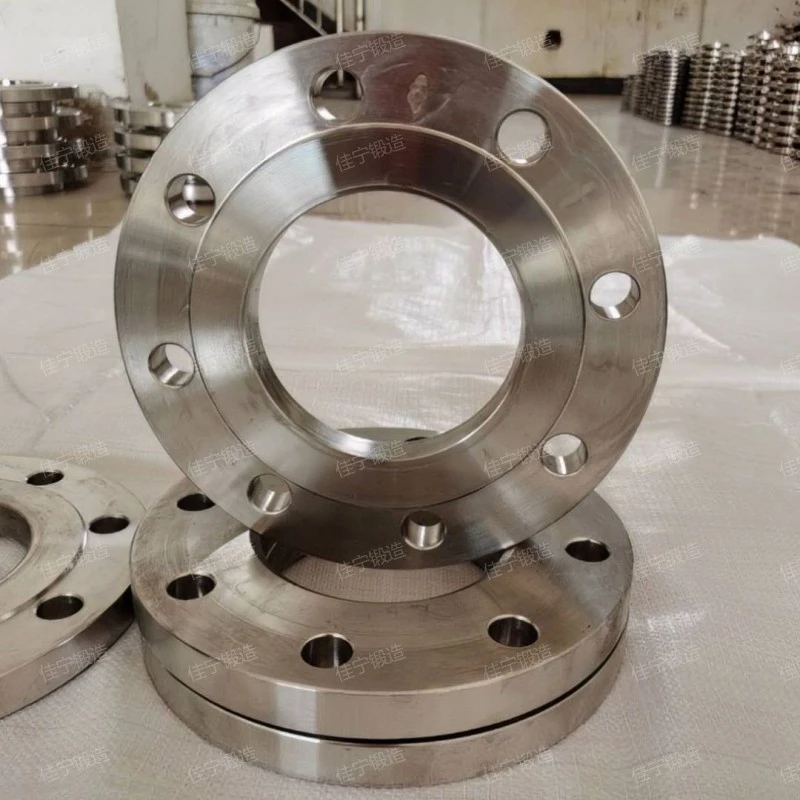

4、Physical picture of Wind turbine shaft free forging

Various specifications and models of Wind turbine shaft free forging are displayed for our customers to visit.。

Wind turbine shaft free forging

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

5、Wind turbine shaft free forging quotation

The Wind turbine shaft free forging price is introduced as follows:

- After-sales service level

- Company size

- quality factor

- product costs

- raw material

Service factors always affect the sales price of products, and high-quality service will make customers have greater satisfaction and recognition. The service factors mainly include pre-sales service, in-sales service and after-sales service. For each stage of service, our company takes the price factor into account and makes a reasonable judgment between service and price, so that the Wind turbine shaft free forging price and service can meet the actual needs of customers.

Our factory is a direct selling manufacturer of Wind turbine shaft free forging, with independent production and processing facilities, few circulation links and low circulation cost.

The quality of the Wind turbine shaft free forging is the key factor that affects its price. The manufacturer of high-quality products has high cost in production and high product performance, which can bring higher economic benefits to customers. Because the manufacturer of high-quality products has high production investment, the manufacturer is on the high side when positioning the Wind turbine shaft free forging price.

When it comes to cost, I believe everyone has heard the saying "You get what you want for a price", which shows that the upfront cost of a product is directly proportional to its value. The upfront cost is high, the value is high, the quality is good, and the price is naturally high. The less the cost is, the lower the price is, and the quality is not good.

The quality of material selection is one of the main factors that directly affect the Wind turbine shaft free forging. If the quality of material selection is better, the price may be more expensive. Therefore, customers must first understand the quality of material selection before purchasing products, and then compare whether the quality and price match.

Wind turbine shaft free forging

6、Jianing's strength

The company has many years of Wind turbine shaft free forging manufacturing experience, large scale and strong strength.。

Jianing forging

Wind turbine shaft free forgingthe product looks atmospheric.,Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、After forging, its structure and mechanical properties can be improved.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Wind turbine shaft free forging can be improved.,the product looks beautiful.。

Related recommendation

-

What is a Plate type flat welded carbon steel flange? flange specifications, models, and parameters

2025-5-26 -

What is a Square tube plate flange? Introduction to the advantages and characteristics of tube sheet functions

2025-5-26 -

What is a DN2400 flange plate? Introduction to the Working Principle of flange

2025-5-26 -

油任模锻件

2024-12-10 -

What is a Square plate flange? How much is the price of the flange?

2025-5-26 -

What is a DN50 flange plate? Introduction to the Working Principle of flange

2025-5-26 -

Introduction to Steel flat welded flange ring and flange working principle

2025-5-26 -

What is a Welded flange with holes? Introduction to the advantages and characteristics of the flange

2025-5-26 -

Introduction to Sealing surface A-type flat welding flange, advantages, characteristics and principles of flange

2025-5-26 -

Introduction to Alloy steel gear, gear advantages, characteristics and principles

2025-5-26