Introduction to Shaft forgings, forging advantages, characteristics and principles

Shaft forgingsforging equipment is used to apply external force to the blank, so that the metal blank is plastically deformed, so as to obtain forgings with required geometric shape and quality.,the product looks beautiful.,After forging, its structure and mechanical properties can be improved.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.,it is an ideal choice for customers to buy Shaft forgings。

1、Brief introduction of Shaft forgings

Shaft forgingsplastic deformation is made to obtain forgings with certain shapes and mechanical properties.,the main features are high-precision, Good mechanical properties, Light weight, High productivity and Great forging flexibility。

Shaft forgings

2、Shaft forgings performance advantage

The advantages of Shaft forgings are as follows:

- Perfect quality assurance system

- Eliminate internal defects

- Perfect quality assurance system

- Optimizing structural design

- high-intensity

In the process of Shaft forgings production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the Shaft forgings.

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the Shaft forgings.

In the process of Shaft forgings production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the Shaft forgings.

On the premise of ensuring the design strength, through reasonable structural design, the Shaft forgings can be lighter than the casting, thus reducing the overall weight of the machine or equipment and reducing energy consumption and cost.

Through forging, the internal structure of the metal is denser and the grain is refined, thus improving the strength of the material. Hot forging promotes crystallization and grain refinement, which enables materials to achieve the greatest possible strength and consistency, and reduces the variation between parts.

Shaft forgings

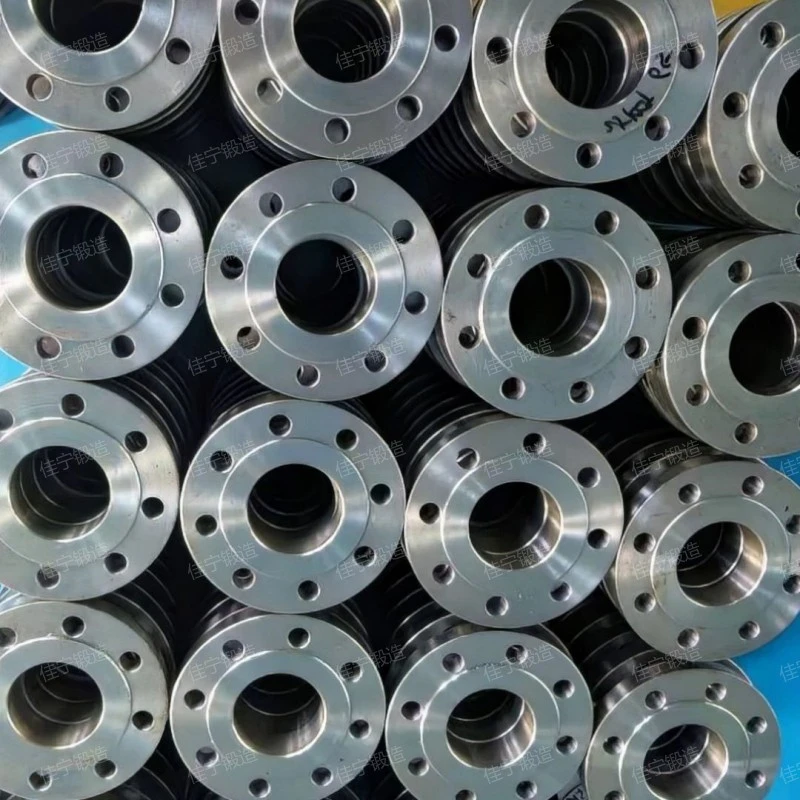

3、Shaft forgings work site real shot

Jianing Shaft forgings manufacturers, a variety of series of Shaft forgings with high-definition pictures at a glance, showing the product style, for the majority of users to choose at will.。

Shaft forgings

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

4、Shaft forgings HD real shot

Jianing provides customers with on-site high-definition video, fully demonstrates the advantages of on-site Shaft forgingst operation, and helps customers to deeply understand the product production process and production site, and gain favorable comments and recognition from customers.。

Shaft forgings

As you can see from the live video.,Jianing the advantage is Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Shaft forgings can be improved.、After forging, its structure and mechanical properties can be improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Shaft forgings.。

5、Shaft forgings HD real picture

Exquisite design, advanced technology and complete sizes and models are available for customers to choose at will.。

Shaft forgings

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

6、Shaft forgings price

The Shaft forgings price is introduced as follows:

- market supply and demand

- regional advantages

- product quality

- Product technology

- marketing channel

The difference between the supply and demand of manufacturers and customers will also affect the Shaft forgings price. When the demand of customers on the market increases and the supply of products by manufacturers is small, the Shaft forgings price will increase with the increase of demand. On the contrary, when the supply of product manufacturers on the market exceeds the demand of customers, the Shaft forgings price will decrease.

If the location of the manufacturer is superior, its transportation will be more convenient. Jianing forging address:Xinzhou has convenient transportation, which provides a good convenience for the transportation of Shaft forgings.

Quality is the key factor to determine the price. A high-quality product requires a lot of manpower, material resources and raw materials, so the manufacturing cost of the product is high. Therefore, the price of high-quality products is high. On the contrary, the price of Shaft forgings is low.

The more advanced the technology, the higher the price will be, otherwise the product price will be low, and customers must pay attention to whether their own technology meets the production requirements when purchasing products.

What kind of sales methods manufacturers have has an intuitive impact on product prices. If it is a direct selling manufacturer, the manufacturer sells directly to customers, and there is no intermediate price difference, which can benefit customers to a greater extent.

Shaft forgings

Shaft forgingsit has been widely used in shipping, construction machinery, metallurgy, manufacturing industry, rail traffic and other industries,is a kind of high quality and low price Shaft forgings。

Related recommendation

-

行车轮

2024-12-10 -

What is a Round threaded flange cover? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

冶金轧辊毛坯锻件

2024-12-10 -

Introduction to Threaded clamping flange and flange advantages and features

2025-5-26 -

What is a 45 # steel shaft forging parts? Introduction to the principle of forging structure

2025-5-26 -

What is a Plate type reducing flange cover? Introduction to the advantages and characteristics of flange functions

2025-5-26 -

What is a Converge panel flat welding flange cover? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

Introduction to Irregular tube plate, tube sheet advantages, characteristics and principles

2025-5-26 -

Introduction to DN20 flange and flange structure principle

2025-5-26 -

What is a 16MnCr5 forging? Introduction to the advantages, characteristics, and principles of the forging

2025-5-26