Introduction to Spindle free forging, how much is the price of the forging?

Spindle free forgingis a workpiece or blank obtained by forging and deforming a metal blank.,it is widely used in war industry, shipping, pressure vessel, construction machinery and metallurgy,the product looks atmospheric.,the advantage is Forging can eliminate metal porosity and holes, and improve the mechanical properties of Spindle free forging.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、After forging, its structure and mechanical properties can be improved.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.,has been favored by more and more customers.。

1、Brief introduction of Spindle free forging

Spindle free forgingforging equipment is used to apply external force to the blank, so that the metal blank is plastically deformed, so as to obtain forgings with required geometric shape and quality.,it has the characteristics of high tenacity, Good anti-fatigue performance, Great forging flexibility, Save raw materials and High production efficiency,the product looks atmospheric.,Cheap and high quality。

Spindle free forging

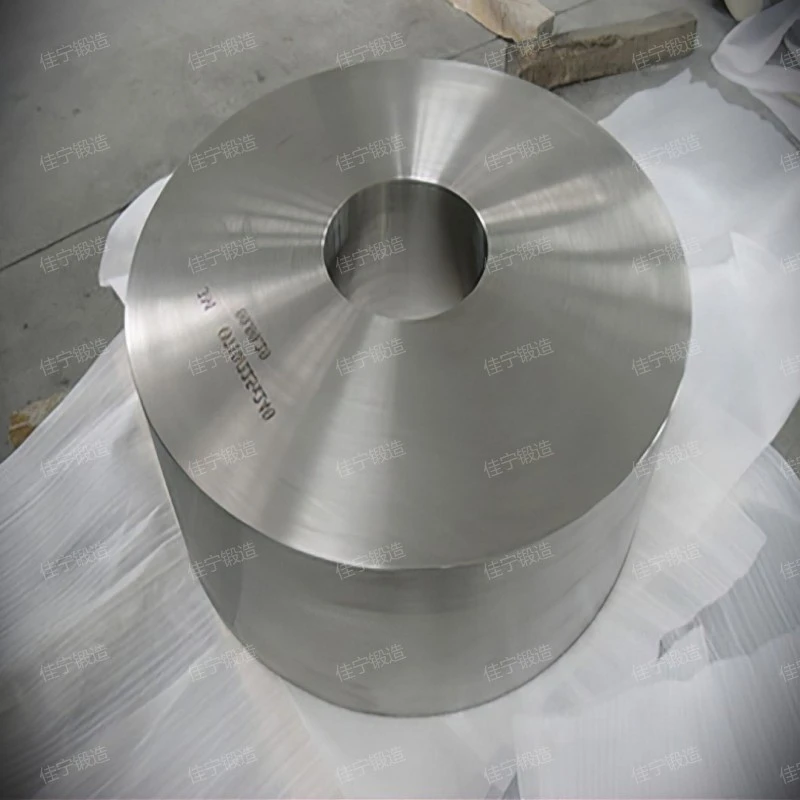

2、Spindle free forging picture

The following pictures can be used for reference by new and old customers.。

Spindle free forging

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

3、Spindle free forging characteristics

Spindle free forgingCan bear large impact force or heavy load.,Light weight,high-precision,Good mechanical properties,high-precision。

Spindle free forging

4、Introduction of advantages of Spindle free forging

The advantages of Spindle free forging are as follows:

- Good chemical uniformity

- Good fatigue resistance.

- Replace other processing methods

- high tenacity

- Replace other processing methods

Forging can disperse the segregation of alloy or nonmetal and make the Spindle free forging have excellent chemical uniformity.

The particle flow inside the Spindle free forging flows precisely along the contour of the part, and these continuous streamline lines are beneficial to reduce the incidence of fatigue or common faults.

In some cases, Spindle free forging can replace parts produced by other processing methods (such as casting, welding, etc.), thus simplifying the production process and improving production efficiency.

The fiber structure of the Spindle free forging is reasonably distributed, which improves the toughness of the material and enables the Spindle free forging to bear greater impact force and alternating stress.

In some cases, Spindle free forging can replace parts produced by other processing methods (such as casting, welding, etc.), thus simplifying the production process and improving production efficiency.

Spindle free forging

5、Spindle free forging price consultation

The Spindle free forging price is introduced as follows:

- Product configuration difference

- product costs

- specifications and models

- product quality

- technology content

The overall configuration has a great influence on the price. Generally speaking, the higher the configuration, the higher its cost input and the higher the selling price of the product, which is beyond doubt. Jianing has made a comprehensive thinking on the overall configuration of products, and at the same time has strictly controlled the material selection and design of products, so the price of products with the same configuration can easily meet the actual purchasing needs of customers.

The cost of manufacturing Spindle free forging varies from manufacturer to manufacturer. The higher the cost of manufacturing products, the higher the product price will be. On the other hand, the lower the production cost, the lower the product price, but the quality of products with high production cost is guaranteed, which can reduce the maintenance cost of customers.

Jianing Spindle free forging has various specifications and models, and the prices of different specifications and models are also different. The main difference lies in the different technologies used in the products and the different manufacturing costs. Jianing forging Sell products at lower prices, so that every customer can enjoy preferential prices

As we all know, the service life of products with excellent quality will be longer, and at the same time, the benefits created by such products for customers will be higher, which will lead to an increase in the cost of products and a high sales price of products.

High-tech products need more advanced technology to support them, so products with higher performance will also lead to a general increase in their prices, and vice versa.

Spindle free forging

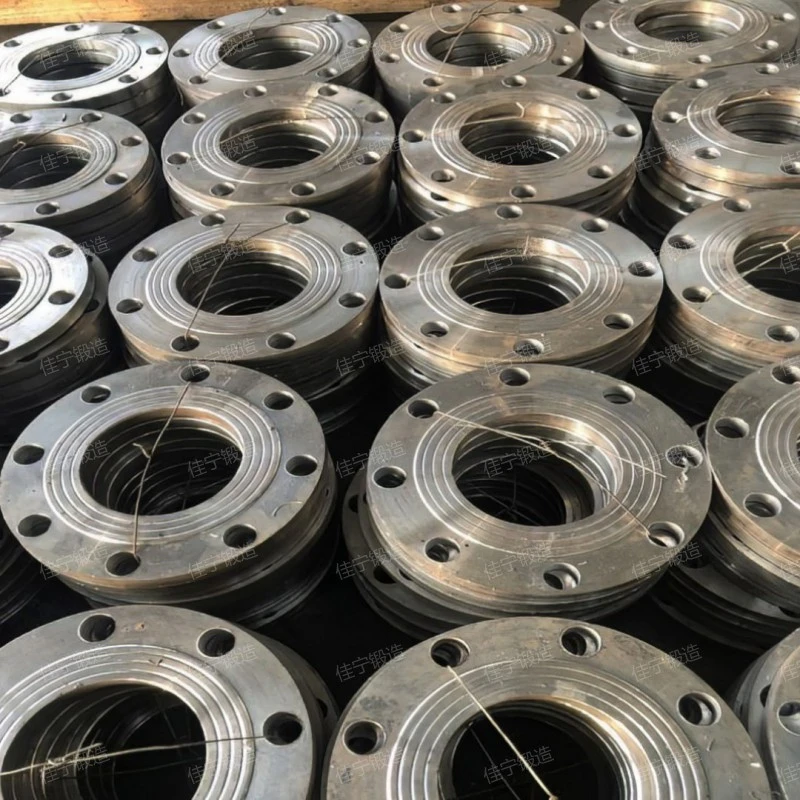

6、Jianing workshop real shot

The finished products of the Spindle free forging factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Jianing forging

The finished products of the Spindle free forging factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Spindle free forgingis a part or blank in which a metal blank is plastically deformed under pressure to obtain the required shape, size and performance.,features include High productivity, high-intensity, Can bear large impact force or heavy load., Good mechanical properties and Good anti-fatigue performance。

Related recommendation

-

What is a Bearing steel forgings? Introduction to the Working Principle of forging

2025-5-26 -

扁平环锻件

2024-12-10 -

Introduction to Mold steel pressure vessel forgings, how much is the price of the forging?

2025-5-26 -

Introduction to Variable diameter convex flange, how much is the price of the flange?

2025-5-26 -

Introduction to SAE butt welding flange, introduction to flange advantages and characteristics

2025-5-26 -

What is a Bottom forging of cylinder? Introduction to the advantages and characteristics of the forging

2025-5-26 -

Introduction to 321 stainless steel butt welded flange, introduction to flange function advantages and characteristics

2025-5-26 -

常规轧机轧辊毛坯锻件

2024-12-10 -

What is a Orifice plate threaded flange? flange specifications, models, and parameters

2025-5-26 -

What is a Roller forging? Introduction to the principle of forging structure

2025-5-26