What is a Shaft seat forging parts? Introduction to the advantages and characteristics of the forging

Shaft seat forging partsrefers to the workpiece or blank obtained by forging metal blank. In the process of forging, the metal blank is plastically deformed under the pressure of forging hammer, press and other equipment, and then its shape, size and organizational structure are changed to meet specific use requirements.,the main features are high-precision, High productivity, High production efficiency, Save raw materials and Good mechanical properties,it is an ideal choice for customers to buy Shaft seat forging parts。The following is to introduce the Shaft seat forging parts:

1、Brief introduction of Shaft seat forging parts

Shaft seat forging partsrefers to the workpiece or blank obtained by forging metal blank.,it has been widely used in rail traffic, war industry, shipping, pressure vessel, metallurgy and other industries,the product looks atmospheric.,is developed and improved by Jianing。

Shaft seat forging parts

2、Functional advantages of Shaft seat forging parts

Shaft seat forging partss have the following advantages.

- Optimizing structural design

- Replace other processing methods

- High degree of automation

- high-intensity

- Good chemical uniformity

On the premise of ensuring the design strength, through reasonable structural design, the Shaft seat forging parts can be lighter than the casting, thus reducing the overall weight of the machine or equipment and reducing energy consumption and cost.

In some cases, Shaft seat forging parts can replace parts produced by other processing methods (such as casting, welding, etc.), thus simplifying the production process and improving production efficiency.

Modern forging equipment has a high degree of automation, which can realize continuous and efficient production and greatly improve production efficiency.

Through forging, the internal structure of the metal is denser and the grain is refined, thus improving the strength of the material. Hot forging promotes crystallization and grain refinement, which enables materials to achieve the greatest possible strength and consistency, and reduces the variation between parts.

Forging can disperse the segregation of alloy or nonmetal and make the Shaft seat forging parts have excellent chemical uniformity.

Shaft seat forging parts

3、Introduction of Shaft seat forging parts characteristics

Shaft seat forging partsGreat forging flexibility,Save raw materials,Good mechanical properties,Good anti-fatigue performance,Light weight,the product looks beautiful.,is a Shaft seat forging parts newly developed by Jianing forging。

Shaft seat forging parts

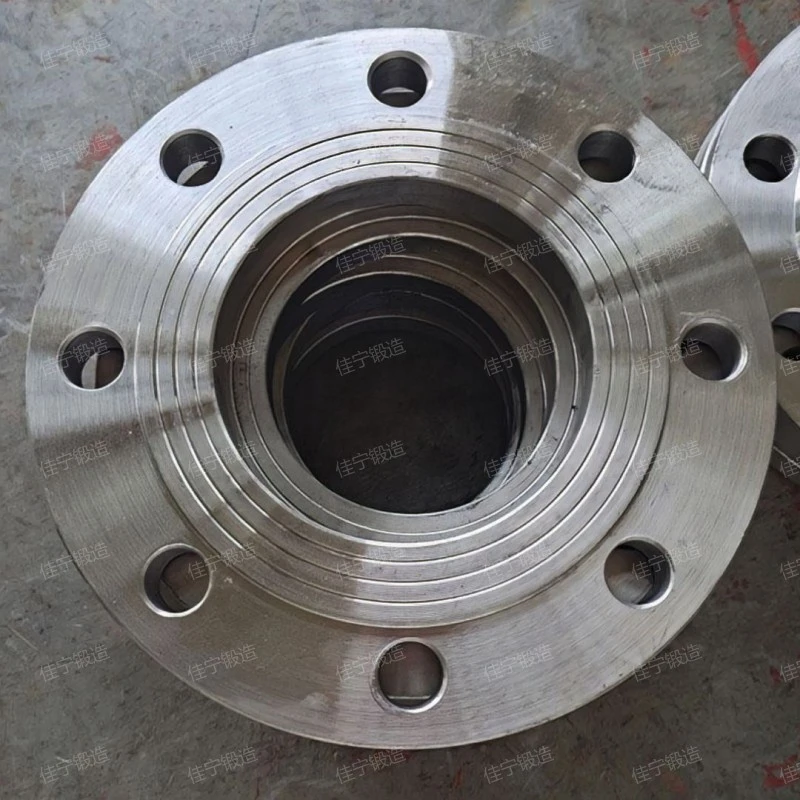

4、On-site real shot of Shaft seat forging parts

A high-definition picture list of Shaft seat forging parts is available for our customers to visit. The physical visit can be made to the factory. The address of the visit is Shanxi Xinzhou, and the time can be reserved in advance. The manufacturer has a special person to receive it.。

Shaft seat forging parts

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

5、Shaft seat forging parts video

Jianing provides customers with on-site high-definition video, fully demonstrates the advantages of on-site Shaft seat forging partst operation, and helps customers to deeply understand the product production process and production site, and gain favorable comments and recognition from customers.。

Shaft seat forging parts

As you can see from the live video.,Shanxi jianing forging co., ltd the product looks beautiful.。

6、Shaft seat forging parts price advantage

The Shaft seat forging parts price is introduced as follows:

- Manufacturer's sales model

- Parameter size

- market quotation

- company strength

- Service factor

If there is no middleman to earn the difference, then the Shaft seat forging parts price will naturally decrease. Jianing adopts the business model of "self-production and self-marketing" to sell products, thus realizing "one-on-one" sales, so the comprehensive price of our products is relatively high.

Because there are many specifications and models of Shaft seat forging parts, the quotations of Shaft seat forging parts with different specifications and models are different.

When the market demand for Shaft seat forging parts is relatively high, manufacturers will raise the price in order to get more profits. On the contrary, when the market demand for this product is low, manufacturers will lower the price in order to sell the remaining products as soon as possible.

The nature of the manufacturer can also greatly affect the price of the Shaft seat forging parts. General manufacturers are divided into direct sellers, agents and middlemen. If they are direct selling manufacturers, there are not too many intermediate links, and their sales prices are low.

Service factors always affect the sales price of products, and high-quality service will make customers have greater satisfaction and recognition. The service factors mainly include pre-sales service, in-sales service and after-sales service. For each stage of service, our company takes the price factor into account and makes a reasonable judgment between service and price, so that the Shaft seat forging parts price and service can meet the actual needs of customers.

Shaft seat forging parts

Shaft seat forging partsrefers to the workpiece or blank obtained by forging metal blank.,it is widely used in energy, power, war industry, automobile, energy and other industries,is a popular Shaft seat forging parts。

Related recommendation

-

Introduction to PN160 flange cover, flange advantages, characteristics and principles

2025-5-26 -

Introduction to Wind power foundation ring flange, introduction to flange function advantages and characteristics

2025-5-26 -

Introduction to Pipe sleeve flange ring, introduction to flange advantages and characteristics

2025-5-26 -

What is a Rotary oil cylinder forging? Introduction to the principle of forging structure

2025-5-26 -

What is a Convex panel flat welding flange? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

What is a Convex concave flange? Introduction to the principle of flange structure

2025-5-26 -

Introduction to Free forging of pancake type, introduction to forging advantages and characteristics

2025-5-26 -

What is a Step shaft forging parts? Introduction to the Working Principle of forging

2025-5-26 -

What is a PL flat welding flange ring? Introduction to the principle of flange structure

2025-5-26 -

Introduction to Valve body blind flange, advantages, characteristics and principles of blind plate

2025-5-26