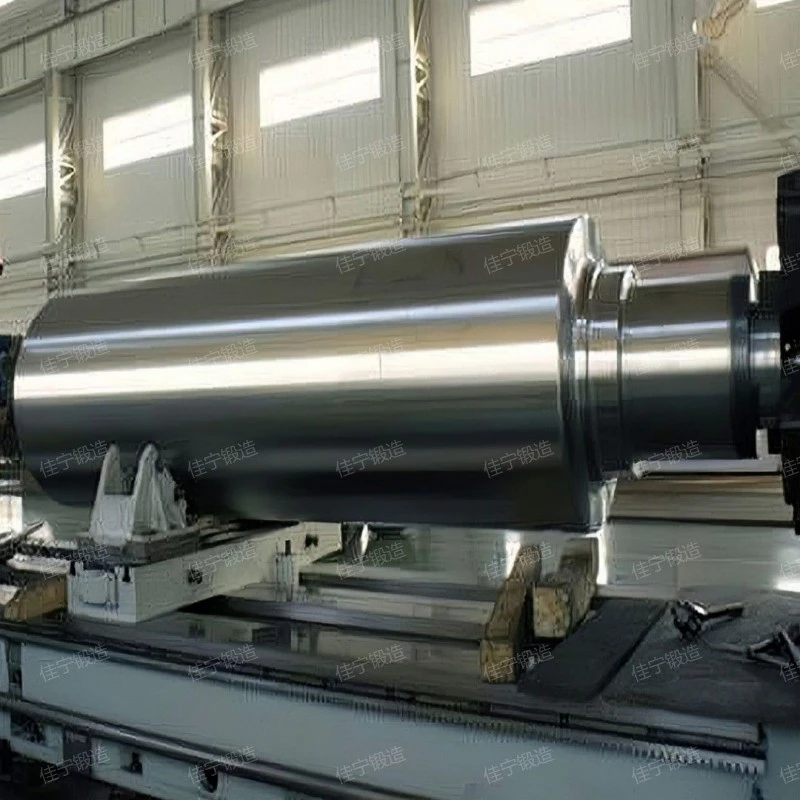

Introduction to Forged shaft sleeve parts and forging structure principle

Forged shaft sleeve partsis the metal that exerts pressure to shape the required shape or appropriate compression through plastic deformation.,it is widely used in energy, pressure vessel, metallurgy, war industry, construction machinery and other industries。The following is to introduce the Forged shaft sleeve parts:

1、Brief introduction of Forged shaft sleeve parts

Forged shaft sleeve partsthe forging machine is used to exert pressure on the blank.,it is widely used in rail traffic, power, automobile, power and metallurgy,is a popular Forged shaft sleeve parts。

Forged shaft sleeve parts

2、Introduction of advantages of Forged shaft sleeve parts

The advantages of Forged shaft sleeve parts are as follows:

- Good fatigue resistance.

- high tenacity

- Good fatigue resistance.

- Replace other processing methods

- Reduce the amount of subsequent processing

The particle flow inside the Forged shaft sleeve parts flows precisely along the contour of the part, and these continuous streamline lines are beneficial to reduce the incidence of fatigue or common faults.

The fiber structure of the Forged shaft sleeve parts is reasonably distributed, which improves the toughness of the material and enables the Forged shaft sleeve parts to bear greater impact force and alternating stress.

The particle flow inside the Forged shaft sleeve parts flows precisely along the contour of the part, and these continuous streamline lines are beneficial to reduce the incidence of fatigue or common faults.

In some cases, Forged shaft sleeve parts can replace parts produced by other processing methods (such as casting, welding, etc.), thus simplifying the production process and improving production efficiency.

The forming precision of the Forged shaft sleeve parts is high, and the subsequent processing amount is relatively small, thus saving the processing cost and time.

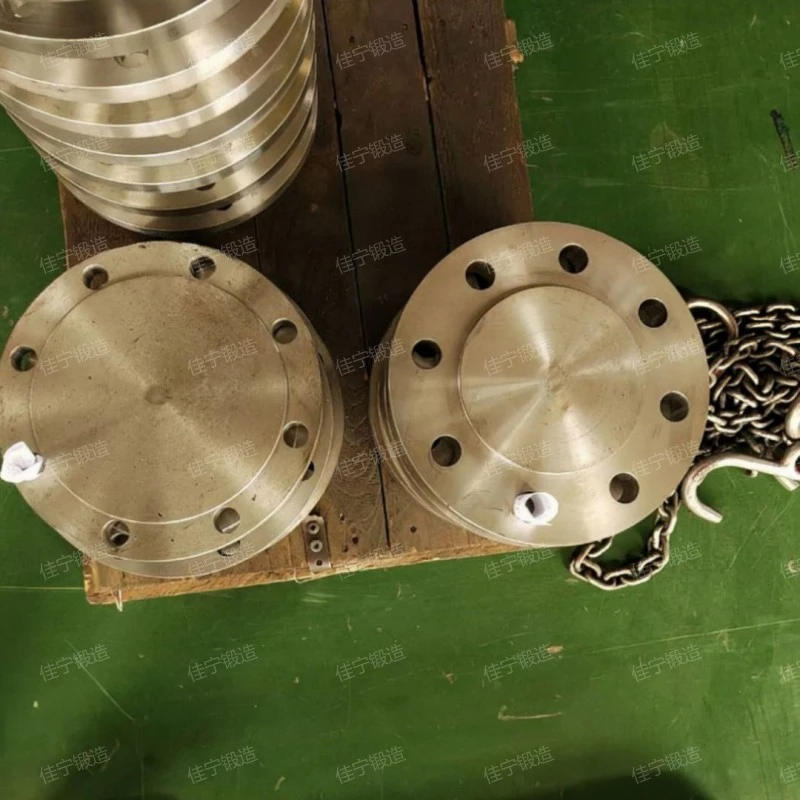

Forged shaft sleeve parts

3、Introduction of Forged shaft sleeve parts characteristics

Forged shaft sleeve partsfeatures include Good mechanical properties, high tenacity, high-precision, High production efficiency and Save raw materials,the product looks beautiful.,it is widely used inshipping,manufacturing industry,construction machinery,automobile,energy and other industries,refers to the workpiece or blank obtained by forging metal blank.,is carefully developed by Jianing forging combined with advanced technology。

Forged shaft sleeve parts

4、Forged shaft sleeve parts video live broadcast

You can buy Forged shaft sleeve parts according to your needs and show you product videos.。

Forged shaft sleeve parts

As you can see from the live video.,Jianing the main features are Can bear large impact force or heavy load., Light weight, Good anti-fatigue performance, High productivity and Great forging flexibility。

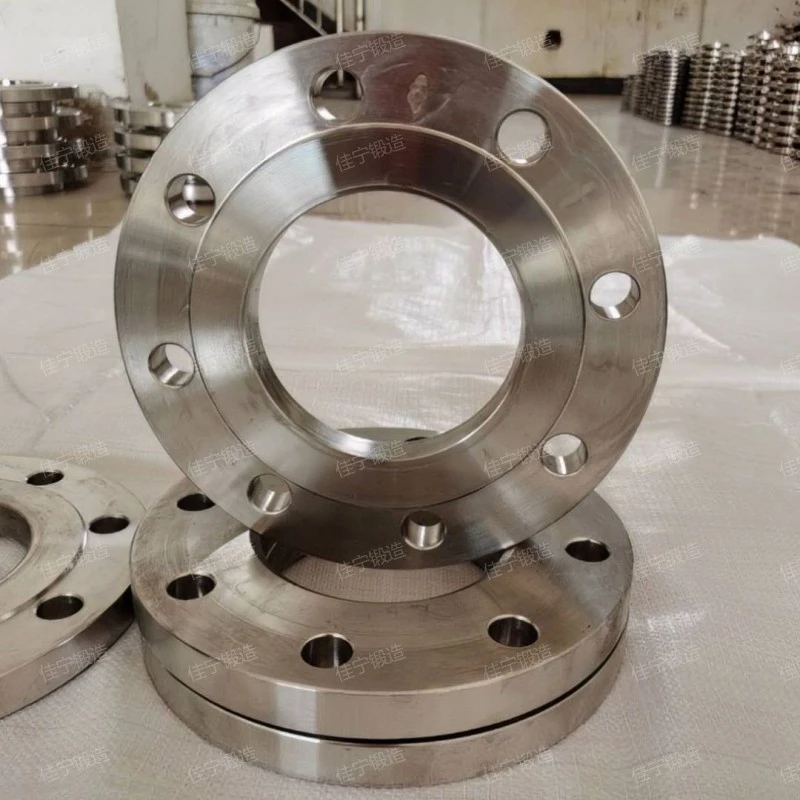

5、Functional advantages of Forged shaft sleeve parts

Forged shaft sleeve partss have the following advantages.

- Optimizing structural design

- Perfect quality assurance system

- High degree of automation

- Good chemical uniformity

- Eliminate internal defects

On the premise of ensuring the design strength, through reasonable structural design, the Forged shaft sleeve parts can be lighter than the casting, thus reducing the overall weight of the machine or equipment and reducing energy consumption and cost.

In the process of Forged shaft sleeve parts production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the Forged shaft sleeve parts.

Modern forging equipment has a high degree of automation, which can realize continuous and efficient production and greatly improve production efficiency.

Forging can disperse the segregation of alloy or nonmetal and make the Forged shaft sleeve parts have excellent chemical uniformity.

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the Forged shaft sleeve parts.

Forged shaft sleeve parts

6、How much is the Forged shaft sleeve parts?

The Forged shaft sleeve parts price is introduced as follows:

- service

- technology

- cost of production

- Manufacturer scale

- mass discrepancy

There is a close relationship between service and price. High-quality service can not only avoid all worries in the process of product use, but also improve the overall strength and comprehensive credibility of manufacturers. In order to improve the service quality, Jianing forging Forged shaft sleeve parts manufacturers provide comprehensive services for customers and products before, during and after sale, and at the same time make the price as favorable as possible to new and old customers, so that the Forged shaft sleeve parts price can meet the purchasing needs of customers.

The more advanced the technology, the higher the price will be, otherwise the product price will be low, and customers must pay attention to whether their own technology meets the production requirements when purchasing products.

A Forged shaft sleeve parts needs to spend a lot of manufacturing costs from research and development to production to sales, including raw material costs, technical costs, labor costs, etc. The higher the manufacturing cost, the higher the price will be.

Our company's expected profit value of Forged shaft sleeve parts is relatively low, and adopts the sales policy of small profits but quick turnover, so the price positioning of Forged shaft sleeve parts is relatively low.

Quality is an important and fundamental factor that affects the price of Forged shaft sleeve parts. In the final analysis, its price depends on its quality. Usually, Forged shaft sleeve parts with better quality will cost more, and such products have better effects, longer service life and more advanced technology. A Forged shaft sleeve parts with a relatively general quality will cost less, have a shorter service life and have a relatively general use effect.

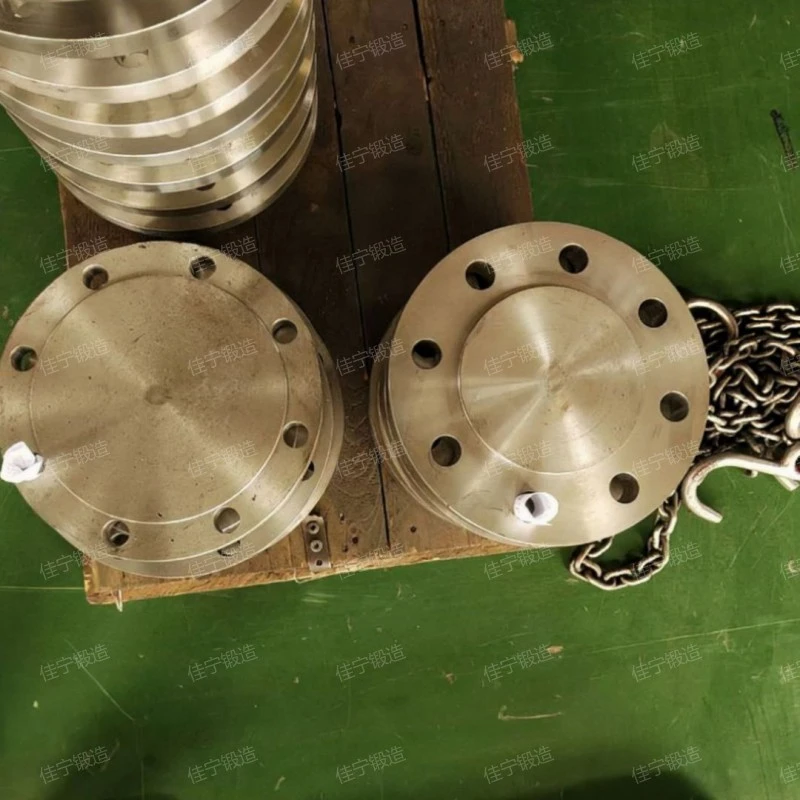

Forged shaft sleeve parts

Forged shaft sleeve partswidely used in shipping, war industry, energy, rail traffic, pressure vessel and other fields,is a part or blank in which a metal blank is plastically deformed under pressure to obtain the required shape, size and performance.,usually used in construction machinery, manufacturing industry, war industry, power, metallurgy and other fields。

Related recommendation

-

What is a Flat welding flange plate with protruding plate? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

What is a 12CrMoV forged parts? How much is the price of the forging?

2025-5-26 -

Introduction to Aluminum alloy tube sheet, tube sheet advantages, characteristics and principles

2025-5-26 -

Introduction to Conical shaft forgings, introduction to forging advantages and characteristics

2025-5-26 -

What is a 30 # steel free forging? Introduction to the advantages and characteristics of the forging

2025-5-26 -

Introduction to Steam kettle flange cover and flange advantages and features

2025-5-26 -

Introduction to Plate type flat welding flange ring and flange structure principle

2025-5-26 -

Introduction to Free forging of oil cylinder and forging structure principle

2025-5-26 -

Introduction to Deep hole tube plate, tube sheet advantages, characteristics and principles

2025-5-26 -

What is a Alloy steel annular free forging? forging specifications, models, and parameters

2025-5-26