Introduction to Roll shaft forging parts, advantages, characteristics and principles of forging

Roll shaft forging partsplastic deformation is made to obtain forgings with certain shapes and mechanical properties.,is a common Roll shaft forging parts,the advantage is Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、After forging, its structure and mechanical properties can be improved.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Roll shaft forging parts can be improved.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.,the product looks atmospheric.,is developed and improved by Jianing。

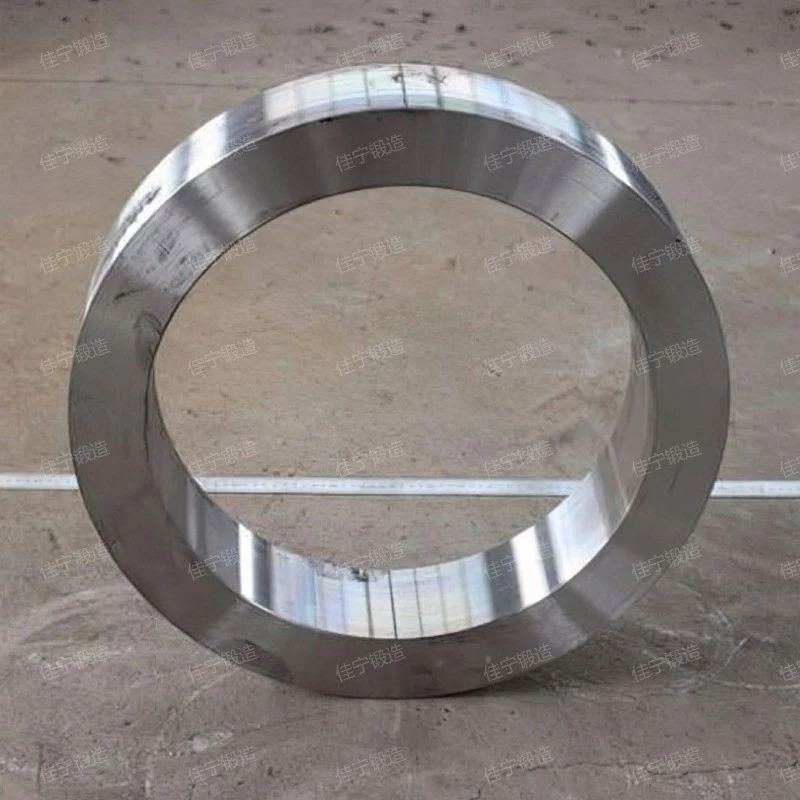

1、Brief introduction of Roll shaft forging parts

Roll shaft forging partsis a workpiece or blank obtained by forging and deforming a metal blank.。

Roll shaft forging parts

2、Roll shaft forging parts HD picture

Excellent materials, atmospheric design, fine workmanship, impeccable, trustworthy, all-round high-definition shooting, which is helpful for customers' reference.。

Roll shaft forging parts

Note: All the pictures in this article were taken by Jianing manufacturer.。

3、Roll shaft forging parts advantage

The advantages of Roll shaft forging parts are as follows:

- Reduce the amount of subsequent processing

- Improve material utilization rate

- Eliminate internal defects

- Replace other processing methods

- Meet the requirements of complex working conditions

The forming precision of the Roll shaft forging parts is high, and the subsequent processing amount is relatively small, thus saving the processing cost and time.

In the process of Roll shaft forging parts production, through accurate blanking and forging process, the utilization rate of raw materials can be maximized and waste can be reduced.

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the Roll shaft forging parts.

In some cases, Roll shaft forging parts can replace parts produced by other processing methods (such as casting, welding, etc.), thus simplifying the production process and improving production efficiency.

The Roll shaft forging parts has excellent mechanical properties and structural integrity, which can meet the use requirements under complex working conditions and ensure the long-term stable operation of the equipment.

Roll shaft forging parts

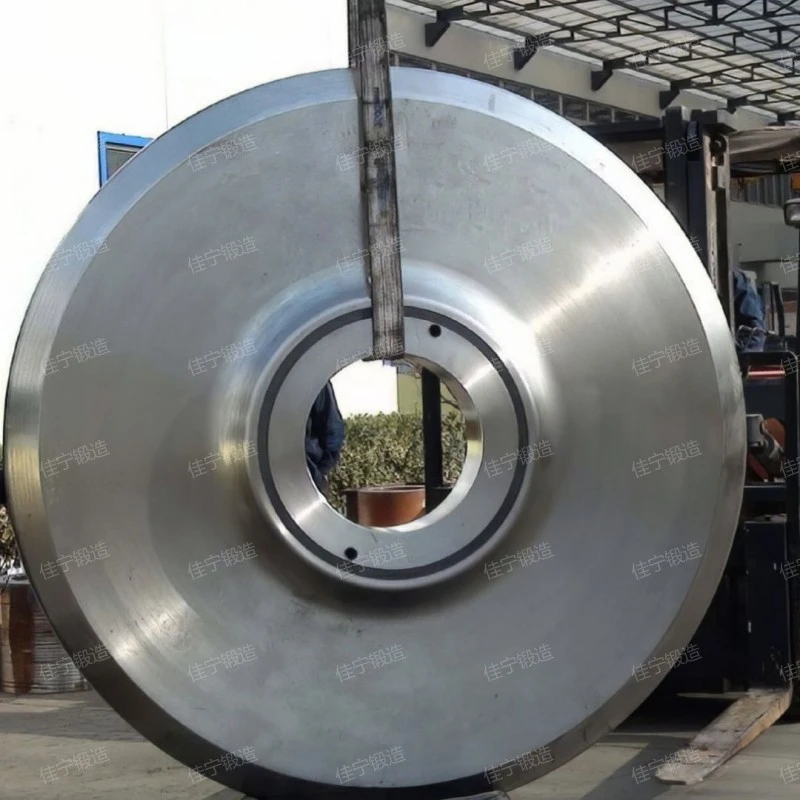

4、Roll shaft forging parts video detail

The following is the live video of Roll shaft forging parts designed and produced by Jianing forging for users, from which we can see the the advantage is After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、After forging, its structure and mechanical properties can be improved.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Roll shaft forging parts. of JianingRoll shaft forging parts.。

Roll shaft forging parts

As you can see from the live video.,Jianing forging is a Roll shaft forging parts。

5、Roll shaft forging parts price concessions

The Roll shaft forging parts price is introduced as follows:

- deploy

- Manufacturer scale

- Quality advantages and disadvantages

- type of operation

- technology content

The higher the hardware configuration, the greater the product cost, so the sales price of such products will be higher. Jianing pays special attention to the hardware configuration of products, so Jianing forging Roll shaft forging parts has a higher cost performance.

There are many Roll shaft forging parts manufacturers on the market. Different manufacturers spend different costs, such as material costs, labor costs, manufacturing costs, etc., and their products are quoted differently.

The price of Roll shaft forging parts is affected by the quality of products. Only when the products are of good quality can we create greater profits for customers and recover the costs for customers as soon as possible. However, products with good quality have a lot of investment in technology, manpower and time, so their prices are higher than those of ordinary products. On the contrary, the products of general quality are equal in effort and gain, and the sales price is also low. But there are exceptions. Many manufacturers often adopt the mode of small profits but quick turnover. If customers can choose products with high cost performance, it is a good choice for long-term investment.

Manufacturers mainly implement the sales mode of small profits but quick turnover and online direct sales. The prices of products are generally low, and the prices are clearly marked, and they will not be more expensive at will. In addition, manufacturers mainly establish communication and negotiation relations with customers through the Internet and telephone, which can greatly reduce the investment in facade expenses, and the production cost of manufacturers is low, so the price of Roll shaft forging parts is low.

The more advanced the technology, the higher the price will be, otherwise the product price will be low, and customers must pay attention to whether their own technology meets the production requirements when purchasing products.

Roll shaft forging parts

6、Jianing's strength

The company has many years of Roll shaft forging parts manufacturing experience, large scale and strong strength.。

Jianing forging

Roll shaft forging partsusually used in energy, rail traffic, automobile, metallurgy, war industry and other fields,the product looks atmospheric.。

Related recommendation

-

What is a 40Mn2 forged parts? How much is the price of the forging?

2025-5-26 -

Introduction to 40CrMo free forging, introduction to forging function advantages and characteristics

2025-5-26 -

What is a Valve cover free forging? Introduction to the advantages, characteristics, and principles of the forging

2025-5-26 -

Introduction to Integral flange plate and flange structure principle

2025-5-26 -

What is a Quick detachable flange? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

What is a High carbon steel flange plate? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

What is a Flat welded tenon groove flange? Introduction to the Working Principle of flange

2025-5-26 -

Introduction to Six hole butt welded flange and flange working principle

2025-5-26 -

What is a Vertical ring forging? How much is the price of the forging?

2025-5-26 -

What is a Flat welding concave convex sealing surface flange cover? Introduction to the principle of flange structure

2025-5-26