What is a Axle forgings? forging specifications, models, and parameters

Axle forgingsis a workpiece or blank obtained by forging and deforming a metal blank.,it can be used in manufacturing industry, power, shipping, rail traffic, metallurgy and other industries,is a Axle forgings。The following is to introduce the Axle forgings:

1、Brief introduction of Axle forgings

Axle forgingsrefers to the workpiece or blank obtained by forging metal blank.,Light weight,High productivity,High production efficiency,high-precision,Great forging flexibility,is designed by Jianing with advanced technology。

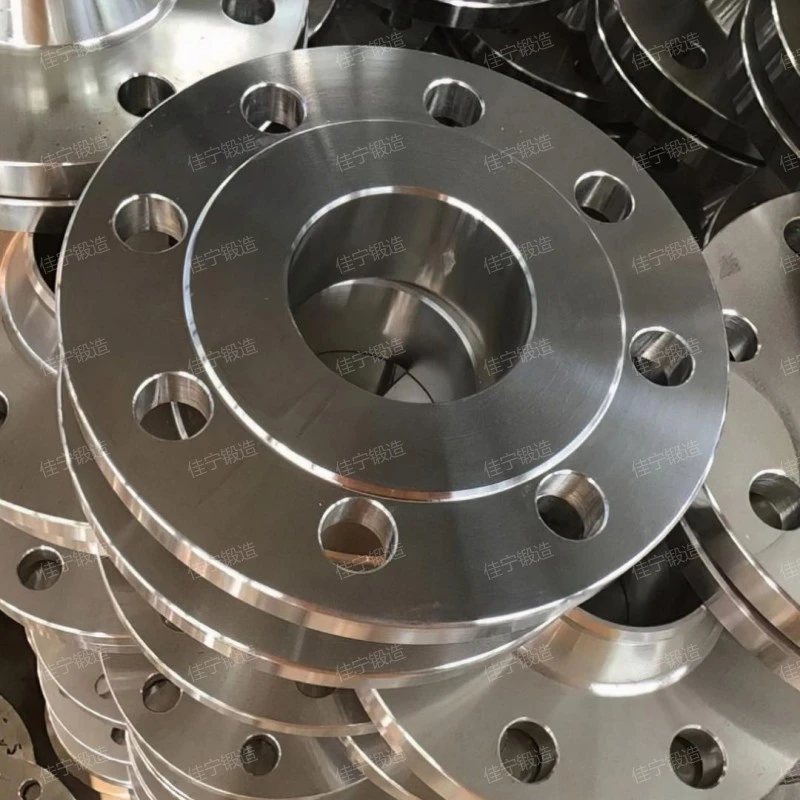

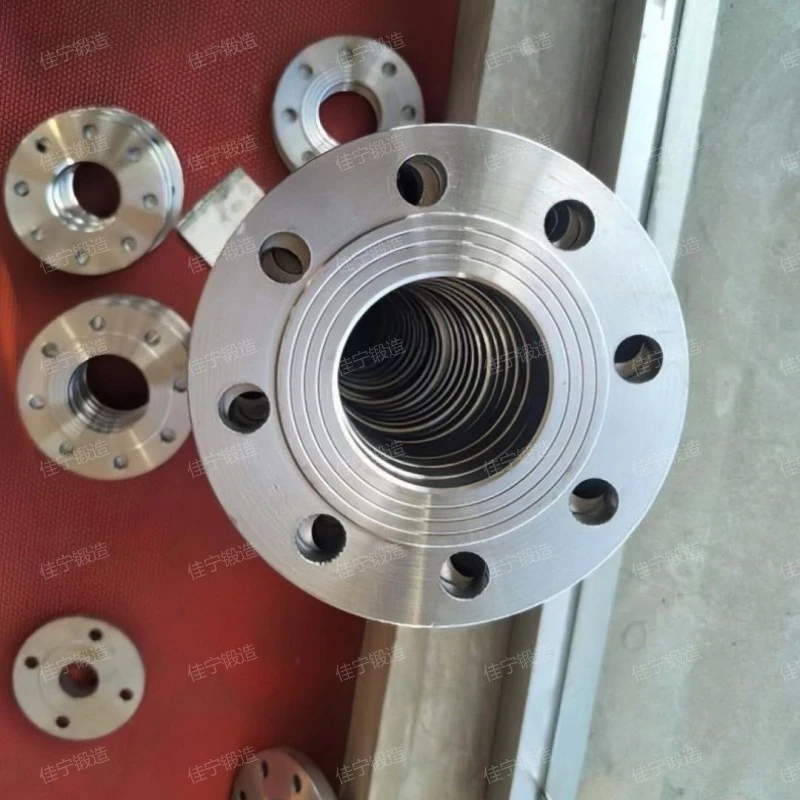

Axle forgings

2、Axle forgings HD picture real shot

Exquisite design, advanced technology and complete sizes and models are available for customers to choose at will.。

Axle forgings

Note: All the pictures in this article were taken by Jianing manufacturer.。

3、Axle forgings characteristics

Axle forgingsit has the characteristics of Can bear large impact force or heavy load., Good mechanical properties, Save raw materials, High production efficiency and Can bear large impact force or heavy load.,is the metal that exerts pressure to shape the required shape or appropriate compression through plastic deformation.,the advantage is After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Axle forgings.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Axle forgings.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Axle forgings can be improved.。

Axle forgings

4、Functional advantages of Axle forgings

Axle forgingss have the following advantages.

- Good chemical uniformity

- Reduce the amount of subsequent processing

- Improve material utilization rate

- Optimizing structural design

- Reduce the amount of subsequent processing

Forging can disperse the segregation of alloy or nonmetal and make the Axle forgings have excellent chemical uniformity.

The forming precision of the Axle forgings is high, and the subsequent processing amount is relatively small, thus saving the processing cost and time.

In the process of Axle forgings production, through accurate blanking and forging process, the utilization rate of raw materials can be maximized and waste can be reduced.

On the premise of ensuring the design strength, through reasonable structural design, the Axle forgings can be lighter than the casting, thus reducing the overall weight of the machine or equipment and reducing energy consumption and cost.

The forming precision of the Axle forgings is high, and the subsequent processing amount is relatively small, thus saving the processing cost and time.

Axle forgings

5、Introduction of Axle forgings characteristics

Axle forgingshigh-precision,high-intensity,Great forging flexibility,Good anti-fatigue performance,High productivity,is a popular Axle forgings,has been favored by more and more customers.。

Axle forgings

Axle forgingsis a popular Axle forgings,usually used in power, manufacturing industry, war industry, pressure vessel, rail traffic and other fields,refers to the workpiece or blank obtained by forging metal blank. In the process of forging, the metal blank is plastically deformed under the pressure of forging hammer, press and other equipment, and then its shape, size and organizational structure are changed to meet specific use requirements.。

Related recommendation

-

Introduction to 904L threaded flange cover and flange structure principle

2025-5-26 -

What is a wheel forging? Introduction to the advantages and characteristics of wheel functions

2025-5-26 -

What is a Protruding threaded flange plate? Introduction to the advantages and characteristics of the flange

2025-5-26 -

What is a Free forging of cylinder end cover? Introduction to the advantages, characteristics, and principles of the forging

2025-5-26 -

Introduction to 15CrMo flat welding flange cover, flange specifications, model parameters

2025-5-26 -

What is a Threaded flat welded flange cover? Introduction to the advantages and characteristics of flange functions

2025-5-26 -

Introduction to Quick-opening gear ring forgings and ring gear structure principle

2025-5-26 -

Introduction to DN3400 flange cover, flange advantages, characteristics and principles

2025-5-26 -

What is a Pressure pipeline flange cover? Introduction to the principle of flange structure

2025-5-26 -

What is a Carbon steel pressure vessel free forging? Introduction to the advantages, characteristics, and principles of the forging

2025-5-26