Introduction to Forged shaft components, introduction to forging function advantages and characteristics

Forged shaft componentsis a workpiece or blank obtained by forging and deforming a metal blank.,Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Forged shaft components.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Forged shaft components can be improved.。The following is to introduce the Forged shaft components:

1、Brief introduction of Forged shaft components

Forged shaft componentsthe forging machine is used to exert pressure on the blank.,is a popular Forged shaft components,is carefully developed by Jianing combined with advanced technology。

Forged shaft components

2、Introduction of Forged shaft components characteristics

Forged shaft componentsfeatures include Good mechanical properties, high tenacity, High production efficiency, high-intensity and High productivity,refers to the workpiece or blank obtained by forging metal blank.,is a part or blank in which a metal blank is plastically deformed under pressure to obtain the required shape, size and performance.,the product looks beautiful.,is designed by Jianing with advanced technology。

Forged shaft components

3、Forged shaft components characteristics

Forged shaft componentsfeatures include High production efficiency, high-precision, Can bear large impact force or heavy load., Great forging flexibility and Save raw materials,is a kind of high quality and low price Forged shaft components,the advantage is After forging, its structure and mechanical properties can be improved.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Forged shaft components can be improved.。

Forged shaft components

4、Forged shaft components advantage

The advantages of Forged shaft components are as follows:

- Eliminate internal defects

- Replace other processing methods

- High dimensional accuracy

- Improve material utilization rate

- Good chemical uniformity

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the Forged shaft components.

In some cases, Forged shaft components can replace parts produced by other processing methods (such as casting, welding, etc.), thus simplifying the production process and improving production efficiency.

In the forging process of Forged shaft components, high dimensional accuracy and shape accuracy can be obtained through the precise forming of dies.

In the process of Forged shaft components production, through accurate blanking and forging process, the utilization rate of raw materials can be maximized and waste can be reduced.

Forging can disperse the segregation of alloy or nonmetal and make the Forged shaft components have excellent chemical uniformity.

Forged shaft components

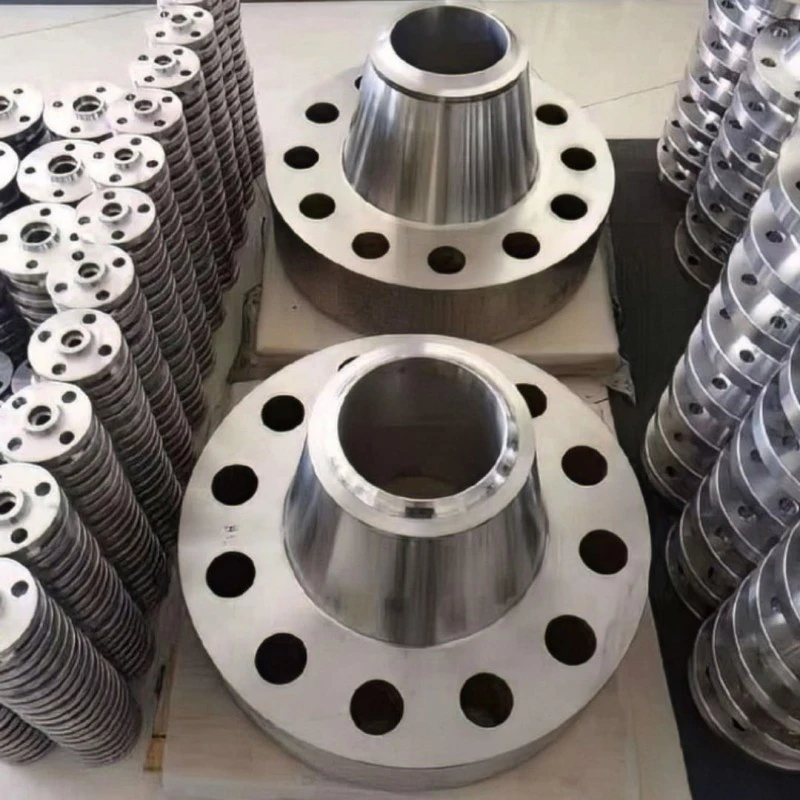

5、Forged shaft components HD real shot

On-site aerial photography of Forged shaft components。

Forged shaft components

As you can see from the live video.,Jianing forging it has the characteristics of Light weight, Good anti-fatigue performance, high tenacity, Good mechanical properties and Great forging flexibility。

6、Forged shaft components price concessions

The Forged shaft components price is introduced as follows:

- product function

- product quality

- service

- Less intermediate links

- model

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

Quality is the fundamental factor that determines the price. The better the quality, the more detailed the manufacturing process, the more careful the materials are, the better the performance is, and the price will naturally be more expensive.

Service factors always affect the sales price of products, and high-quality service will make customers have greater satisfaction and recognition. The service factors mainly include pre-sales service, in-sales service and after-sales service. For each stage of service, our company takes the price factor into account and makes a reasonable judgment between service and price, so that the Forged shaft components price and service can meet the actual needs of customers.

What kind of sales methods manufacturers have has an intuitive impact on product prices. If it is a direct selling manufacturer, the manufacturer sells directly to customers, and there is no intermediate price difference, which can benefit customers to a greater extent.

The same type of equipment, with different models and sizes, has different investment costs, so the quotations to customers are naturally different. Generally speaking, the larger the model, the higher the price, and the smaller the model, the lower the price.

Forged shaft components

Forged shaft componentsplastic deformation is made to obtain forgings with certain shapes and mechanical properties.,it can be used in metallurgy, war industry, pressure vessel, automobile, construction machinery and other industries,the advantage is After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、After forging, its structure and mechanical properties can be improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.。

Related recommendation

-

Introduction to Three-hole gear ring, how much is the price of the ring gear?

2025-5-26 -

Introduction to Petrochemical pressure vessel cylinder forging parts, forging advantages, characteristics and principles

2025-5-26 -

Introduction to Gouzao flange cover, flange advantages, characteristics and principles

2025-5-26 -

What is a Disk forging parts? Introduction to the Working Principle of forging

2025-5-26 -

Introduction to 316L stainless steel butt welded flange cover, flange advantages, characteristics and principles

2025-5-26 -

带颈平焊法兰

2024-12-10 -

冷弯轧辊毛坯锻件

2024-12-10 -

What is a Alloy steel gear ring? Introduction to the advantages, characteristics, and principles of the ring gear

2025-5-26 -

What is a Thin walled flat welding flange? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

What is a Variable diameter connection flange? How much is the price of the flange?

2025-5-26