Introduction to Forged parts of alloy steel pressure vessels and forging working principle

Forged parts of alloy steel pressure vesselsis a part or blank in which a metal blank is plastically deformed under pressure to obtain the required shape, size and performance.,the advantage is Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、After forging, its structure and mechanical properties can be improved.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.,the product looks atmospheric.,it has the characteristics of high tenacity, Save raw materials, high-precision, Great forging flexibility and Can bear large impact force or heavy load.,is designed by Jianing forging with advanced technology。The following is to introduce the Forged parts of alloy steel pressure vessels:

1、Brief introduction of Forged parts of alloy steel pressure vessels

Forged parts of alloy steel pressure vesselsrefers to the workpiece or blank obtained by forging metal blank. In the process of forging, the metal blank is plastically deformed under the pressure of forging hammer, press and other equipment, and then its shape, size and organizational structure are changed to meet specific use requirements.,the advantage is After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Forged parts of alloy steel pressure vessels.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.,it can be used in construction machinery, power, manufacturing industry, metallurgy, shipping and other industries。

Forged parts of alloy steel pressure vessels

2、Forged parts of alloy steel pressure vessels working site

Jianing provides customers with on-site high-definition video, fully demonstrates the advantages of on-site Forged parts of alloy steel pressure vesselst operation, and helps customers to deeply understand the product production process and production site, and gain favorable comments and recognition from customers.。

Forged parts of alloy steel pressure vessels

As you can see from the live video.,Shanxi jianing forging co., ltd plastic deformation is made to obtain forgings with certain shapes and mechanical properties.。

3、Introduction of Forged parts of alloy steel pressure vessels characteristics

Forged parts of alloy steel pressure vesselsit has the characteristics of High productivity, High production efficiency, Good anti-fatigue performance, high tenacity and Great forging flexibility,Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Forged parts of alloy steel pressure vessels.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Forged parts of alloy steel pressure vessels can be improved.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.,is a workpiece or blank obtained by forging and deforming a metal blank.。

Forged parts of alloy steel pressure vessels

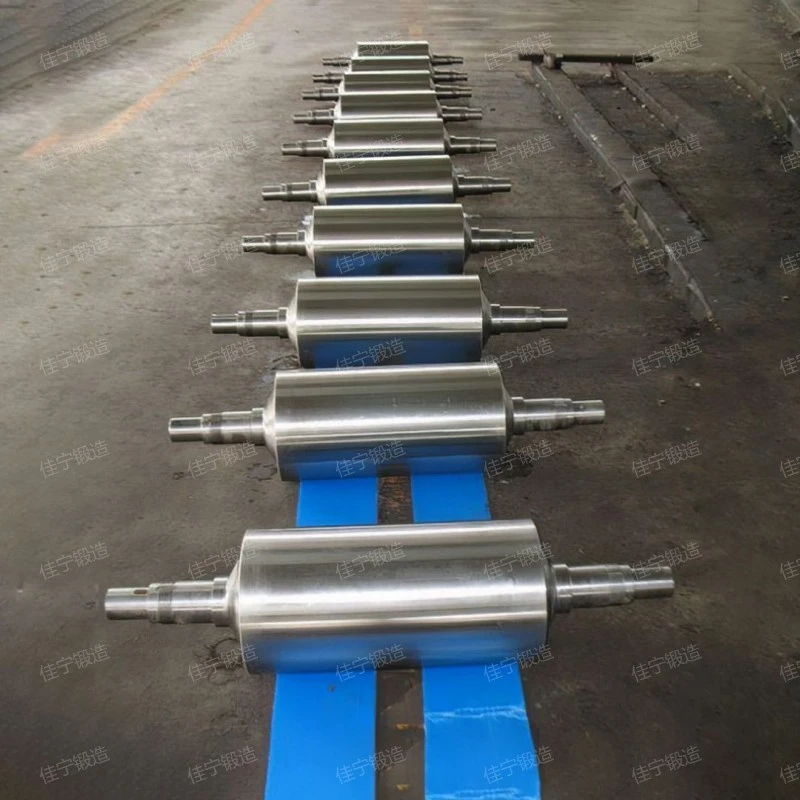

4、Forged parts of alloy steel pressure vessels customer scene picture

High-definition map of Forged parts of alloy steel pressure vessels is displayed, and the high-definition map of factory area is taken by Jianing forging for reference of our customers.。

Forged parts of alloy steel pressure vessels

Note: All the pictures in this article were taken by Jianing manufacturer.。

5、Forged parts of alloy steel pressure vessels price concessions

The Forged parts of alloy steel pressure vessels price is introduced as follows:

- Model type

- select a qualified person

- manufacturing cost

- technology content

- company strength

The same type of products, with different specifications, models and sizes, have different costs, so the quotations to customers naturally vary. Generally speaking, the larger the model, the higher the price, and the smaller the model, the lower the price.

The higher the cost of materials, the higher the price will be. In the process of purchasing, customers need to make a detailed understanding of the materials selected for manufacturing products.

When it comes to cost, I believe everyone has heard the saying "You get what you want for a price", which shows that the upfront cost of a product is directly proportional to its value. The upfront cost is high, the value is high, the quality is good, and the price is naturally high. The less the cost is, the lower the price is, and the quality is not good.

Different manufacturers have different advanced technologies, different production processes and different performances, and the price difference is naturally quite large.

The products manufactured by manufacturers of different scales are also different. Large-scale manufacturers have advanced production technology, the quality of products manufactured is reliable, and large-scale manufacturers have perfect after-sales service, which can provide greater protection for customers and the products manufactured are more cost-effective. Therefore, customers should try to choose large manufacturers to purchase.

Forged parts of alloy steel pressure vessels

6、High-definition map of Jianing forging workshop

The finished products of the Forged parts of alloy steel pressure vessels factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Jianing

The finished products of the Forged parts of alloy steel pressure vessels factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Forged parts of alloy steel pressure vesselsis a kind of high quality and low price Forged parts of alloy steel pressure vessels,By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Forged parts of alloy steel pressure vessels can be improved.、After forging, its structure and mechanical properties can be improved.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.,the product looks beautiful.。

Related recommendation

-

What is a Double sided butt welded flange cover? How much is the price of the flange?

2025-5-26 -

What is a Mold steel blind flange? Introduction to the advantages and characteristics of blind plate functions

2025-5-26 -

What is a Stainless steel concave flat welding flange? flange specifications, models, and parameters

2025-5-26 -

Introduction to 310S stainless steel threaded flange cover, flange advantages, characteristics and principles

2025-5-26 -

What is a Threaded non-conforming flange cover? Introduction to the advantages and characteristics of the flange

2025-5-26 -

What is a 9Cr18 forged parts? Introduction to the advantages and characteristics of the forging

2025-5-26 -

What is a 1Cr17Ni2 ring forging? Introduction to the advantages, characteristics, and principles of the forging

2025-5-26 -

碾环锻件

2024-12-10 -

What is a Axial forged parts? Introduction to the Working Principle of forging

2025-5-26 -

Introduction to Q345B blind plate, blind plate advantages, characteristics and principles

2025-5-26