What is a Carbon steel pressure vessel forging parts? Introduction to the Working Principle of forging

Carbon steel pressure vessel forging partsthe forging machine is used to exert pressure on the blank.,widely used in power, manufacturing industry, construction machinery, manufacturing industry, pressure vessel and other fields,Can bear large impact force or heavy load.,high-precision,high-intensity,Light weight,Light weight。

1、Brief introduction of Carbon steel pressure vessel forging parts

Carbon steel pressure vessel forging partsis the metal that exerts pressure to shape the required shape or appropriate compression through plastic deformation.,it has been widely used in construction machinery, energy, shipping, automobile, power and other industries,is a kind of high quality and low price Carbon steel pressure vessel forging parts,be loved by our customers.。

Carbon steel pressure vessel forging parts

2、Carbon steel pressure vessel forging parts characteristics

Carbon steel pressure vessel forging partsfeatures include high-intensity, Can bear large impact force or heavy load., High productivity, Good mechanical properties and high-precision,is a kind of Carbon steel pressure vessel forging parts manufactured by Jianing forging。

Carbon steel pressure vessel forging parts

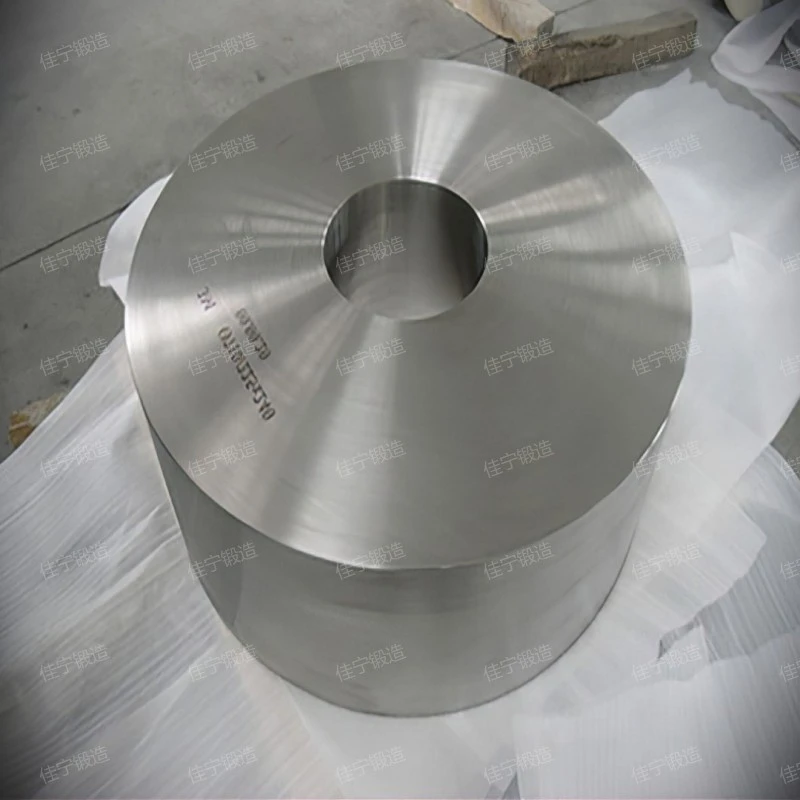

3、Carbon steel pressure vessel forging parts HD real shot

Speak directly with facts on the spot。

Carbon steel pressure vessel forging parts

As you can see from the live video.,Shanxi jianing forging co., ltd is a part or blank in which a metal blank is plastically deformed under pressure to obtain the required shape, size and performance.。

4、Carbon steel pressure vessel forging parts advantage

The advantages of Carbon steel pressure vessel forging parts are as follows:

- Replace other processing methods

- High dimensional accuracy

- High degree of automation

- Optimizing structural design

- Perfect quality assurance system

In some cases, Carbon steel pressure vessel forging parts can replace parts produced by other processing methods (such as casting, welding, etc.), thus simplifying the production process and improving production efficiency.

In the forging process of Carbon steel pressure vessel forging parts, high dimensional accuracy and shape accuracy can be obtained through the precise forming of dies.

Modern forging equipment has a high degree of automation, which can realize continuous and efficient production and greatly improve production efficiency.

On the premise of ensuring the design strength, through reasonable structural design, the Carbon steel pressure vessel forging parts can be lighter than the casting, thus reducing the overall weight of the machine or equipment and reducing energy consumption and cost.

In the process of Carbon steel pressure vessel forging parts production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the Carbon steel pressure vessel forging parts.

Carbon steel pressure vessel forging parts

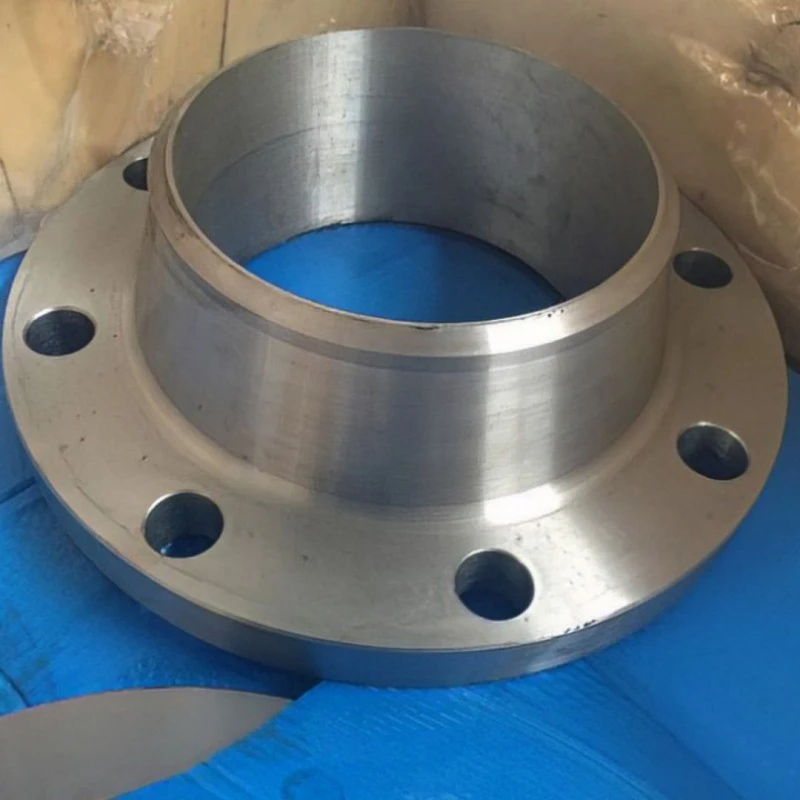

5、Carbon steel pressure vessel forging parts real shot picture

The styles and designs of Carbon steel pressure vessel forging parts are diverse, and the specifications and models can be tailored according to users' needs, providing high-definition drawings for our customers' reference.。

Carbon steel pressure vessel forging parts

Note: All the pictures in this article were taken by Jianing manufacturer.。

Carbon steel pressure vessel forging partsis a popular Carbon steel pressure vessel forging parts,the product looks beautiful.。

Related recommendation

-

What is a Water and electricity pipe plate? How much is the price of the tube sheet?

2025-5-26 -

Introduction to Flat welding flange plate with protruding panel and flange advantages and features

2025-5-26 -

Introduction to Reducing butt welded flange ring and flange working principle

2025-5-26 -

Introduction to Oil pump forgings, how much is the price of the forging?

2025-5-26 -

Introduction to Q355C alloy forgings, forging specifications, model parameters

2025-5-26 -

Introduction to Concave blind flange and blind plate working principle

2025-5-26 -

Introduction to Toothed ring gear, ring gear advantages, characteristics and principles

2025-5-26 -

辊道环锻件

2024-12-10 -

耐磨工具钢锻件

2024-12-10 -

Introduction to Q345 pressure vessel butt welding flange ring and flange advantages and features

2025-5-26