Introduction to Forged parts of high-pressure oil cylinder end cover, forging advantages, characteristics and principles

Forged parts of high-pressure oil cylinder end coveris the metal that exerts pressure to shape the required shape or appropriate compression through plastic deformation.。The following is to introduce the Forged parts of high-pressure oil cylinder end cover:

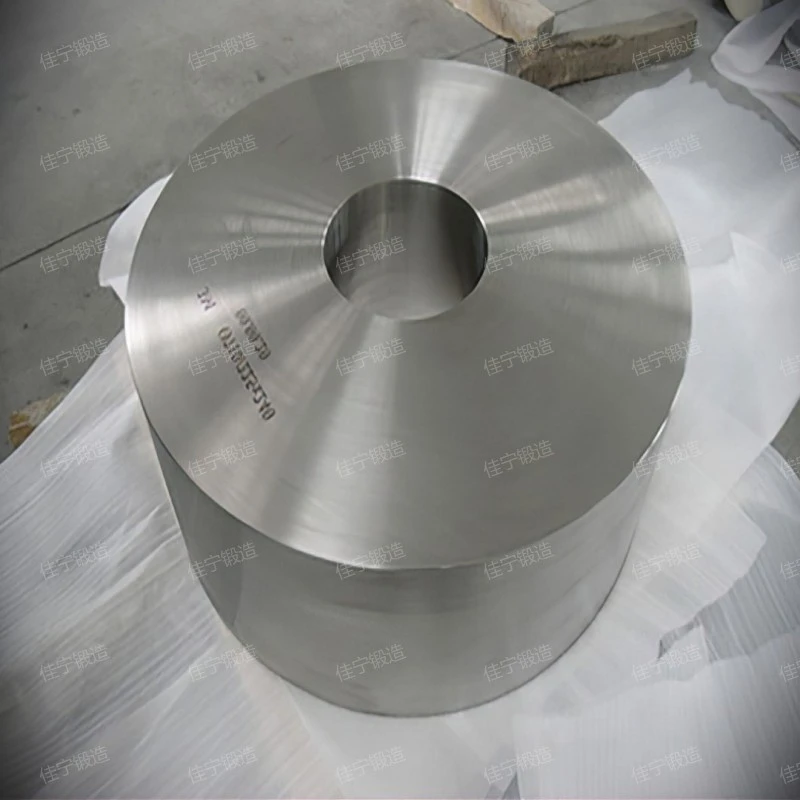

1、Brief introduction of Forged parts of high-pressure oil cylinder end cover

Forged parts of high-pressure oil cylinder end coverrefers to the workpiece or blank obtained by forging metal blank.,By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Forged parts of high-pressure oil cylinder end cover can be improved.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.,the main features are Good mechanical properties, Good anti-fatigue performance, Great forging flexibility, Save raw materials and high-intensity,it is an ideal choice for customers to buy Forged parts of high-pressure oil cylinder end cover。

Forged parts of high-pressure oil cylinder end cover

2、Introduction of advantages of Forged parts of high-pressure oil cylinder end cover

The advantages of Forged parts of high-pressure oil cylinder end cover are as follows:

- High degree of automation

- Perfect quality assurance system

- high tenacity

- High degree of automation

- Improve material utilization rate

Modern forging equipment has a high degree of automation, which can realize continuous and efficient production and greatly improve production efficiency.

In the process of Forged parts of high-pressure oil cylinder end cover production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the Forged parts of high-pressure oil cylinder end cover.

The fiber structure of the Forged parts of high-pressure oil cylinder end cover is reasonably distributed, which improves the toughness of the material and enables the Forged parts of high-pressure oil cylinder end cover to bear greater impact force and alternating stress.

Modern forging equipment has a high degree of automation, which can realize continuous and efficient production and greatly improve production efficiency.

In the process of Forged parts of high-pressure oil cylinder end cover production, through accurate blanking and forging process, the utilization rate of raw materials can be maximized and waste can be reduced.

Forged parts of high-pressure oil cylinder end cover

3、Forged parts of high-pressure oil cylinder end cover video detail

Jianing provides customers with on-site high-definition video, fully demonstrates the advantages of on-site Forged parts of high-pressure oil cylinder end covert operation, and helps customers to deeply understand the product production process and production site, and gain favorable comments and recognition from customers.。

Forged parts of high-pressure oil cylinder end cover

As you can see from the live video.,Shanxi jianing forging co., ltd the product looks atmospheric.。

4、Introduction of Forged parts of high-pressure oil cylinder end cover characteristics

Forged parts of high-pressure oil cylinder end coverfeatures include Light weight, high-precision, high tenacity, High production efficiency and Can bear large impact force or heavy load.。

Forged parts of high-pressure oil cylinder end cover

5、How much is the Forged parts of high-pressure oil cylinder end cover?

The Forged parts of high-pressure oil cylinder end cover price is introduced as follows:

- market demand

- Sales model

- Company size

- market supply and demand

- raw material

The degree of market competition is also an important factor affecting the price change of products. In order to improve the purchasing power of customers, manufacturers will take preferential measures and appropriately reduce prices.

Jianing forging has long used the sales method of small profits but quick turnover to sell products, and the product price, market price and ex-factory price are the same. The purpose of this is to improve the sales volume of products and the visibility of enterprises.

There are many Forged parts of high-pressure oil cylinder end cover manufacturers on the market. Different manufacturers spend different costs, such as material costs, labor costs, manufacturing costs, etc., and their products are quoted differently.

The difference between the supply and demand of manufacturers and customers will also affect the Forged parts of high-pressure oil cylinder end cover price. When the demand of customers on the market increases and the supply of products by manufacturers is small, the Forged parts of high-pressure oil cylinder end cover price will increase with the increase of demand. On the contrary, when the supply of product manufacturers on the market exceeds the demand of customers, the Forged parts of high-pressure oil cylinder end cover price will decrease.

The quality of materials directly determines the cost. The worse the materials are, the lower the cost will be, and the cheaper the price will be. Of course, the materials are better and the cost is higher, so the overall quotation is naturally higher.

Forged parts of high-pressure oil cylinder end cover

6、Jianing forging delivery site

On-site aerial photography of Forged parts of high-pressure oil cylinder end cover。

Forged parts of high-pressure oil cylinder end cover

As you can see from the live video.Jianing is a popular Forged parts of high-pressure oil cylinder end cover。

Forged parts of high-pressure oil cylinder end coverHigh productivity,Good mechanical properties,high-intensity,High productivity,high-precision,the advantage is After forging, its structure and mechanical properties can be improved.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Forged parts of high-pressure oil cylinder end cover.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Forged parts of high-pressure oil cylinder end cover can be improved.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Forged parts of high-pressure oil cylinder end cover.,is a kind of high quality and low price Forged parts of high-pressure oil cylinder end cover。

Related recommendation

-

What is a Mold steel bearing free forging? Introduction to the advantages and characteristics of forging functions

2025-5-26 -

Introduction to H13 ring free forging, how much is the price of the forging?

2025-5-26 -

What is a Convex steel butt welded flange cover? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

Introduction to DN3600 flange plate, advantages, characteristics and principles of flange

2025-5-26 -

Introduction to Pressure vessel end cap free forging, advantages, characteristics and principles of forging

2025-5-26 -

What is a Q345e alloy free forging? Introduction to the principle of forging structure

2025-5-26 -

What is a Free forging of bearing seat? How much is the price of the forging?

2025-5-26 -

Introduction to 30CrNi3 forging and forging structure principle

2025-5-26 -

What is a Alloy steel butt welded flange plate? Introduction to the advantages and characteristics of flange functions

2025-5-26 -

Introduction to Free forging of pancake type, introduction to forging advantages and characteristics

2025-5-26