Introduction to Three types of pressure vessel forging parts, introduction to forging function advantages and characteristics

Three types of pressure vessel forging partsplastic deformation is made to obtain forgings with certain shapes and mechanical properties.,it has the characteristics of Light weight, Can bear large impact force or heavy load., High productivity, Save raw materials and Great forging flexibility,the product looks atmospheric.。

1、Brief introduction of Three types of pressure vessel forging parts

Three types of pressure vessel forging partsrefers to the workpiece or blank obtained by forging metal blank. In the process of forging, the metal blank is plastically deformed under the pressure of forging hammer, press and other equipment, and then its shape, size and organizational structure are changed to meet specific use requirements.,is a common Three types of pressure vessel forging parts,it is widely used in war industry, energy, power, automobile and pressure vessel,the product looks atmospheric.,it is an ideal choice for customers to buy Three types of pressure vessel forging parts。

Three types of pressure vessel forging parts

2、Three types of pressure vessel forging parts characteristics

Three types of pressure vessel forging partsthe main features are high tenacity, high-intensity, Good mechanical properties, Save raw materials and High production efficiency,is a popular Three types of pressure vessel forging parts,the product looks atmospheric.,is designed by Jianing with advanced technology。

Three types of pressure vessel forging parts

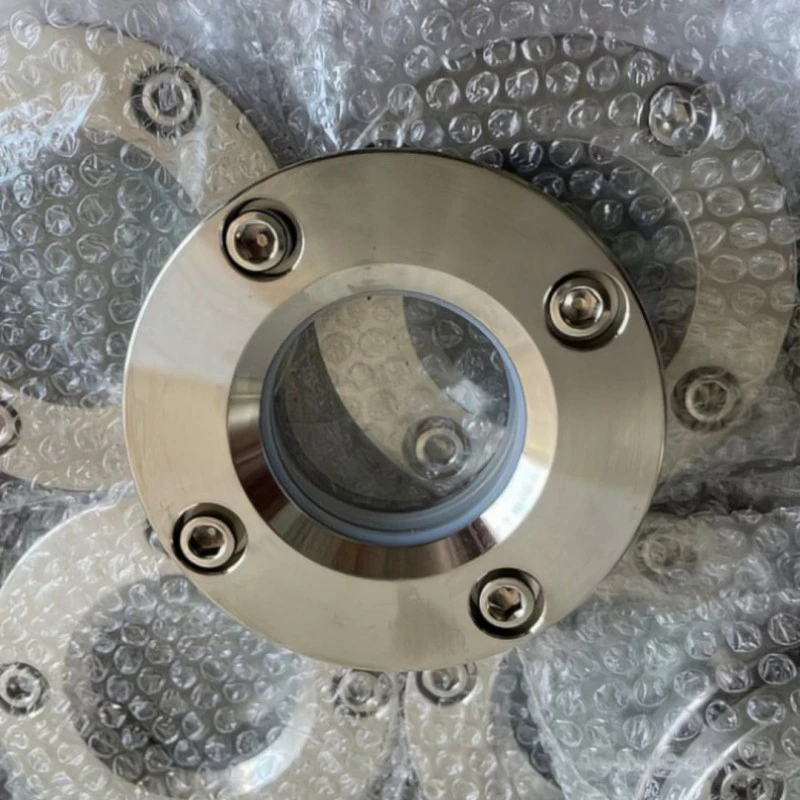

3、Three types of pressure vessel forging parts work site real shot

Three types of pressure vessel forging parts manufacturer, the product High definition shooting. In order to facilitate new and old customers to find satisfactory the product looks beautiful. more quickly, the following high-definition pictures are provided for reference.。

Three types of pressure vessel forging parts

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

4、Three types of pressure vessel forging parts customer scene picture

Different specifications and models of high-definition pictures, so that everyone can see enough at once.。

Three types of pressure vessel forging parts

Note: All the pictures in this article were taken by Jianing manufacturer.。

5、Three types of pressure vessel forging parts HD real shot

The following is the live video of Three types of pressure vessel forging parts designed and produced by Jianing forging for users, from which we can see the the advantage is Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、After forging, its structure and mechanical properties can be improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties. of Three types of pressure vessel forging parts.。

Three types of pressure vessel forging parts

As you can see from the live video.,Shanxi jianing forging co., ltd Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Three types of pressure vessel forging parts can be improved.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Three types of pressure vessel forging parts.、After forging, its structure and mechanical properties can be improved.。

6、Three types of pressure vessel forging parts price concessions

The Three types of pressure vessel forging parts price is introduced as follows:

- Service factor

- Product technology

- Brand strength

- Manufacturer scale

- brand

Service factors always affect the sales price of products, and high-quality service will make customers have greater satisfaction and recognition. The service factors mainly include pre-sales service, in-sales service and after-sales service. For each stage of service, our company takes the price factor into account and makes a reasonable judgment between service and price, so that the Three types of pressure vessel forging parts price and service can meet the actual needs of customers.

The more advanced the technology, the higher the price will be, otherwise the product price will be low, and customers must pay attention to whether their own technology meets the production requirements when purchasing products.

At present, there are various brands of Three types of pressure vessel forging parts in Shanxi. The performance, quality and after-sales of products under different brands are different, and the prices of Three types of pressure vessel forging parts are different.

Direct selling by manufacturers and sales by middlemen will also affect product prices. There are not too many links among direct selling products, so the cost required by manufacturers is low, and the price of Three types of pressure vessel forging parts is low. Customers can also put products into production in advance. On the contrary, when purchasing products from middlemen, there are not only many links, but also the price of Three types of pressure vessel forging parts is much higher, so customers should choose products directly sold by manufacturers when purchasing.

Different brands of products in the same series have more or less differences in product prices, and different brands of Three types of pressure vessel forging parts have more or less differences in price.

Three types of pressure vessel forging parts

Three types of pressure vessel forging partswidely used in war industry, shipping, construction machinery, rail traffic, metallurgy and other fields,high-intensity,Can bear large impact force or heavy load.,High productivity,high tenacity,Good mechanical properties。

Related recommendation

-

Introduction to F55 flat welding flange cover and flange advantages and features

2025-5-26 -

Introduction to Double phase steel butt welding flange, advantages, characteristics and principles of flange

2025-5-26 -

What is a Low temperature welded flange? Introduction to the Working Principle of flange

2025-5-26 -

What is a DN400 flange cover? How much is the price of the flange?

2025-5-26 -

What is a Pump body free forging? Introduction to the Working Principle of forging

2025-5-26 -

What is a Step shaft forging parts? Introduction to the Working Principle of forging

2025-5-26 -

What is a 4130 alloy forged parts? Introduction to the Working Principle of forging

2025-5-26 -

Introduction to Welding flange cover for petrochemical use and flange structure principle

2025-5-26 -

Introduction to Concave flange plate, how much is the price of the flange?

2025-5-26 -

Introduction to Insulation pipe welding flange, advantages, characteristics and principles of flange

2025-5-26