What is a Oil seal end cap free forging? forging specifications, models, and parameters

Oil seal end cap free forgingrefers to the workpiece or blank obtained by forging metal blank. In the process of forging, the metal blank is plastically deformed under the pressure of forging hammer, press and other equipment, and then its shape, size and organizational structure are changed to meet specific use requirements.。The following is to introduce the Oil seal end cap free forging:

1、Brief introduction of Oil seal end cap free forging

Oil seal end cap free forgingrefers to the workpiece or blank obtained by forging metal blank.,features include Great forging flexibility, Good mechanical properties, Save raw materials, high-precision and High productivity。

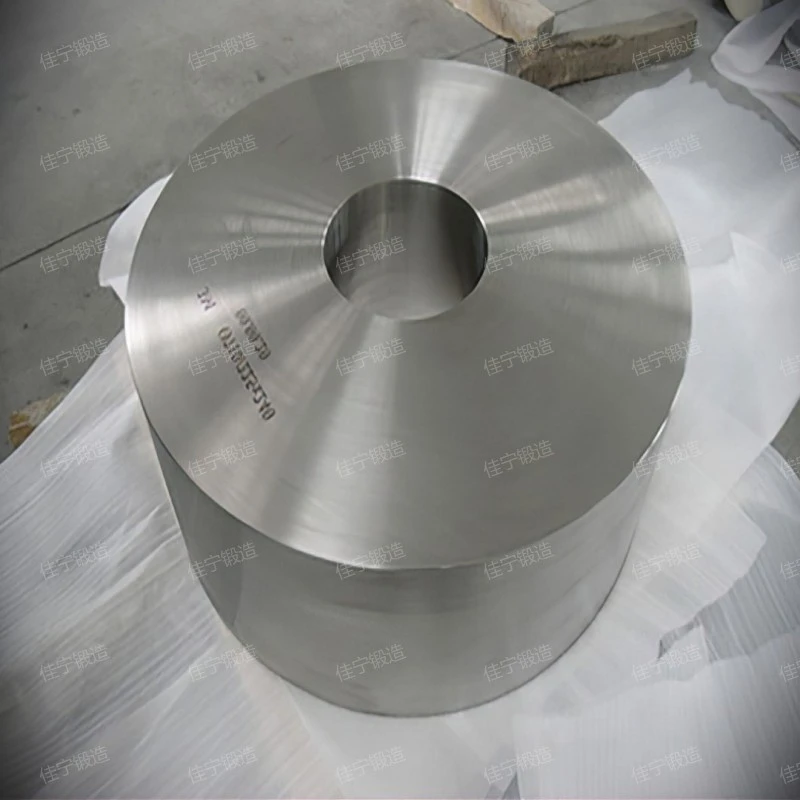

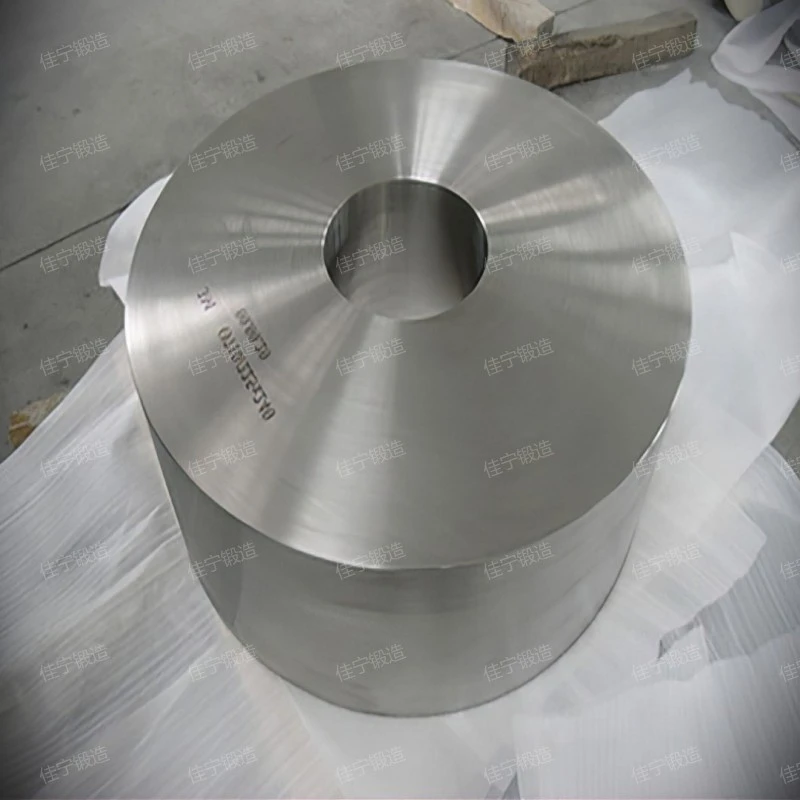

Oil seal end cap free forging

2、Oil seal end cap free forging characteristics

Oil seal end cap free forgingthe main features are Can bear large impact force or heavy load., Good anti-fatigue performance, high-intensity, High production efficiency and High productivity,After forging, its structure and mechanical properties can be improved.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.,the advantage is Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Oil seal end cap free forging can be improved.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Oil seal end cap free forging.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.,has been favored by more and more customers.。

Oil seal end cap free forging

3、Introduction of Oil seal end cap free forging characteristics

Oil seal end cap free forgingit has the characteristics of Good mechanical properties, Can bear large impact force or heavy load., high tenacity, High production efficiency and Great forging flexibility,is the metal that exerts pressure to shape the required shape or appropriate compression through plastic deformation.,it can be used in metallurgy, construction machinery, manufacturing industry, war industry, energy and other industries,is a common Oil seal end cap free forging,the product looks beautiful.。

Oil seal end cap free forging

4、Oil seal end cap free forging HD real shot

Oil seal end cap free forging manufacturer, the product High definition real shot. In order to facilitate new and old customers to find satisfactory the product looks beautiful. more quickly, the following high-definition pictures are provided for reference.。

Oil seal end cap free forging

Note: All the pictures in this article were taken by Jianing manufacturer.。

5、Oil seal end cap free forging video live broadcast

Speak directly with facts on the spot。

Oil seal end cap free forging

As you can see from the live video.,Jianing forging is a workpiece or blank obtained by forging and deforming a metal blank.。

6、How much is the Oil seal end cap free forging?

The Oil seal end cap free forging price is introduced as follows:

- specifications and models

- company strength

- technology

- Less intermediate links

- market quotation

Different customers need different output, different specifications, different product configurations, and their Oil seal end cap free forging prices are also different. The bigger the specification, the stronger the performance of the product and the higher the quotation.

Jianing forging's scale and strength are relatively strong, the technology and technology of products produced by manufacturers are relatively advanced, and there is less waste of resources in the process of manufacturing, and the price of products will be relatively low.

The more advanced the technology, the higher the price will be, otherwise the product price will be low, and customers must pay attention to whether their own technology meets the production requirements when purchasing products.

There are direct selling manufacturers and agents in the market. Agents are higher than direct selling manufacturers, mainly because agents get goods from manufacturers, sell them to customers and earn the difference from middlemen, so the natural price is higher.

The amount of customers' demand for Oil seal end cap free forging in the market also has a great influence on the price. When there are many customers purchasing this product in the market and the supply quantity of manufacturers is small, the Oil seal end cap free forging price will be very high. On the contrary, when fewer customers purchase this product, there will be a phenomenon of oversupply, and the price of Oil seal end cap free forging will naturally be reduced.

Oil seal end cap free forging

Oil seal end cap free forgingthe product looks atmospheric.,is a Oil seal end cap free forging,After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Oil seal end cap free forging can be improved.、After forging, its structure and mechanical properties can be improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.。

Related recommendation

-

铝镁合金车轮锻件

2024-12-10 -

Introduction to Column forging parts, forging advantages, characteristics and principles

2025-5-26 -

What is a Stainless steel flange? Introduction to the advantages and characteristics of flange functions

2025-5-26 -

Introduction to 20 inch flange and flange working principle

2025-5-26 -

Introduction to Docking flat welding flange, advantages, characteristics and principles of flange

2025-5-26 -

What is a 30CrMo forging? Introduction to the advantages and characteristics of forging functions

2025-5-26 -

V80风机主轴毛坯锻件

2024-12-10 -

What is a Free forging of bearing steel ring? Introduction to the advantages and characteristics of forging functions

2025-5-26 -

高碳工具钢锻件

2024-12-10 -

What is a Flat welding flange for mortise and tenon sealing surface? Introduction to the principle of flange structure

2025-5-26